An air separation cold box panel enclosure structure

An enclosure structure and cold box technology, applied in pipeline protection, cold treatment separation, refrigeration and liquefaction, etc., can solve problems such as unreliable structural safety and economics, inconvenient calculation results, and damage to the stress system of the main structure. Review, simple and accurate calculation, and the effect of reducing steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

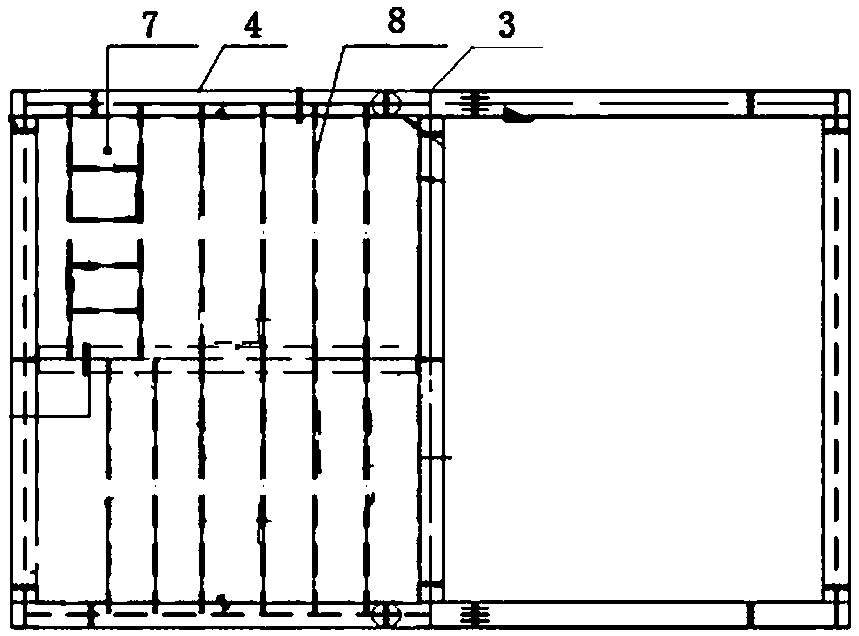

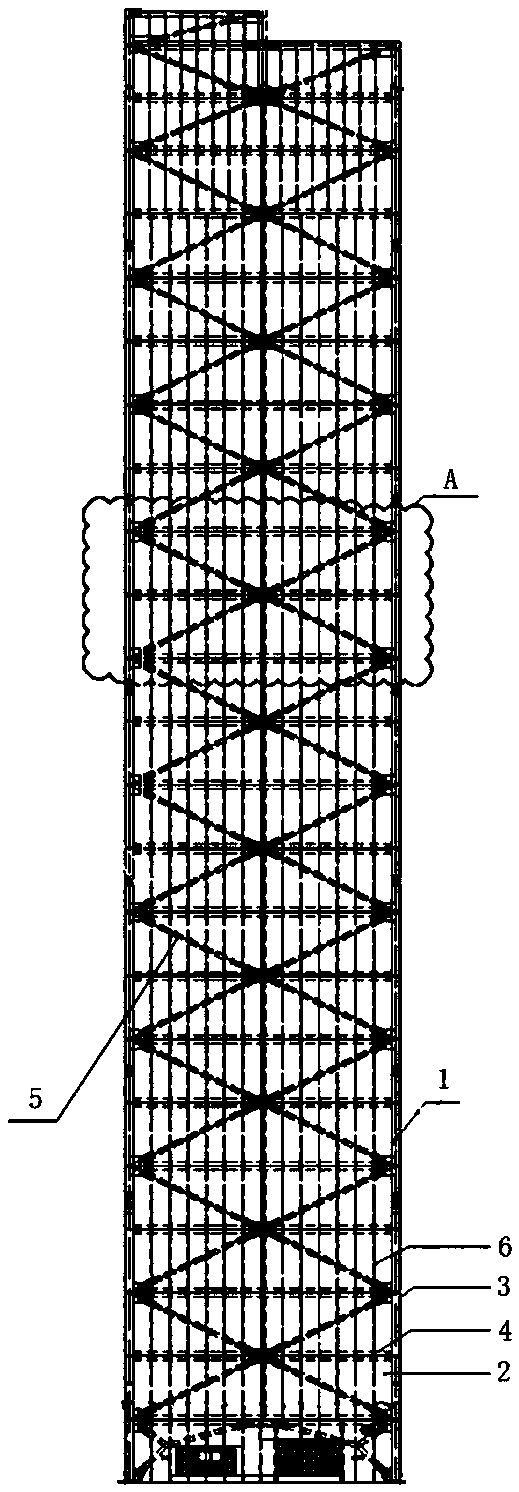

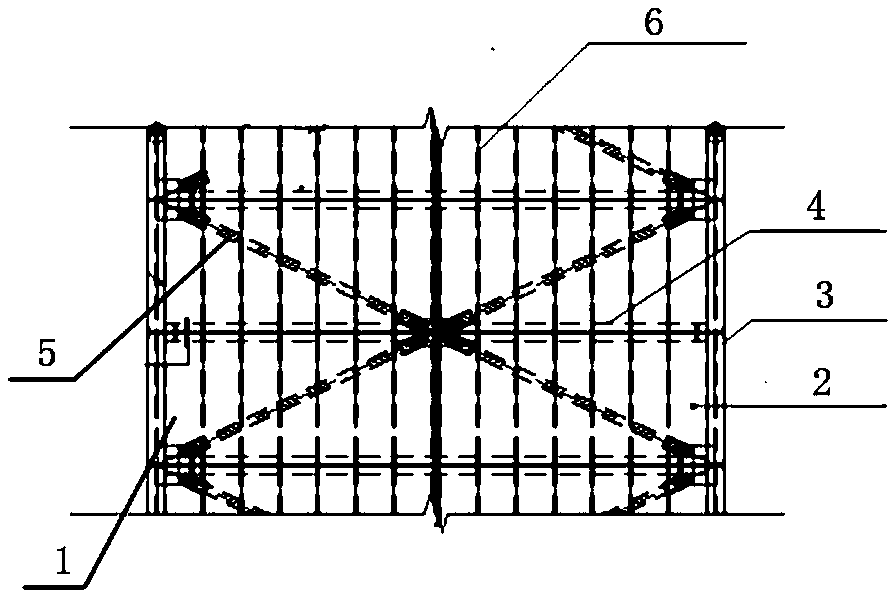

[0016] The present invention will be described in detail below in conjunction with the drawings: Figure 1-3 As shown, an air separation cold box panel enclosure structure according to the present invention is mainly composed of a surrounding truss structure 1 and a cold box panel 2 enclosed on the surrounding truss structure 1, so The truss structure 1 described is composed of long cold box columns 3 on both sides, a plurality of cold box beams 4 fixed on the cold box columns 3 on both sides in turn, and three cold box beams 4 cross-fixed from top to bottom. The box beam 4 is composed of two diagonal braces 5 with the middle of the middle cold box beam as the crossing point. The truss structure 1 is vertically fixed on the cold box beam 4 and horizontally distributed on the cold box beam 4 A plurality of stiffening ribs 6 extending from the bottom to the top; the truss structure 1 is respectively sealed and welded with cold box panels 2 for wrapping the entire cold box.

[0017...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com