Glass fiber/epoxy resin composite material substrate type fiber bragg grating sensor

A technology of epoxy resin and glass fiber, which is applied in the fields of optical fiber communication, sensing and measurement, to achieve the effects of small strain transmission loss, improved performance stability, high strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

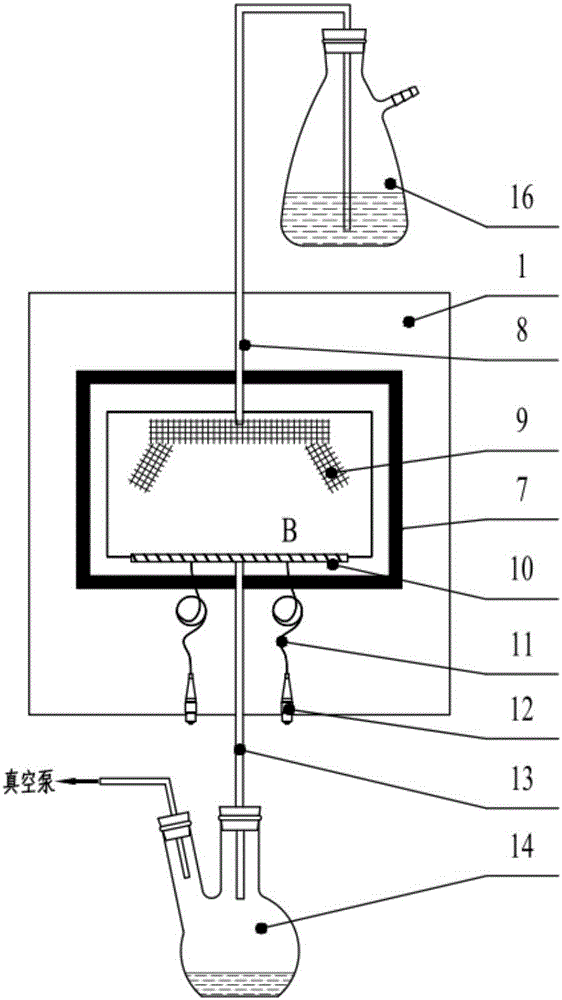

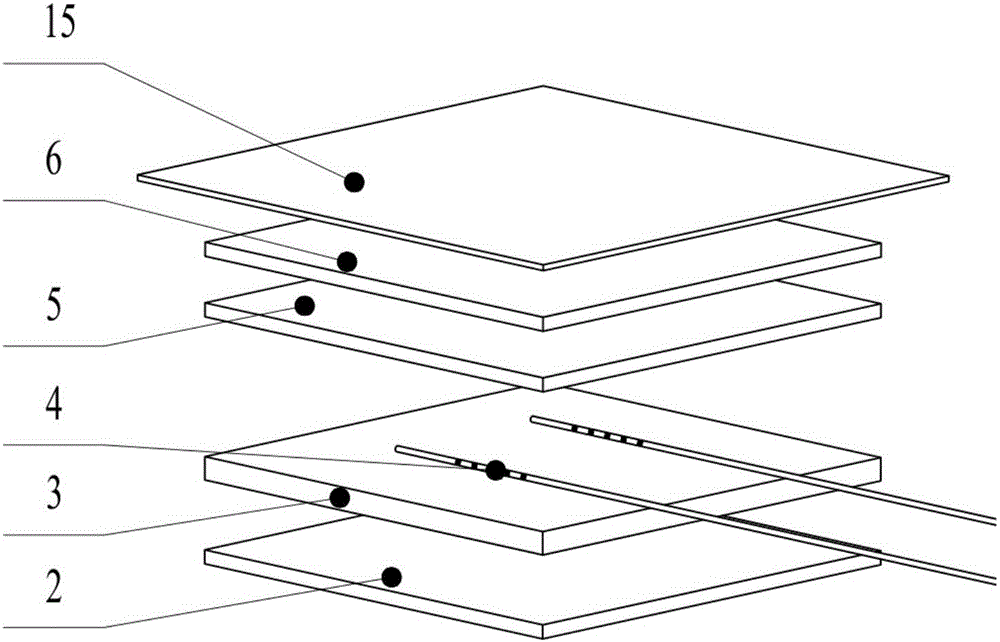

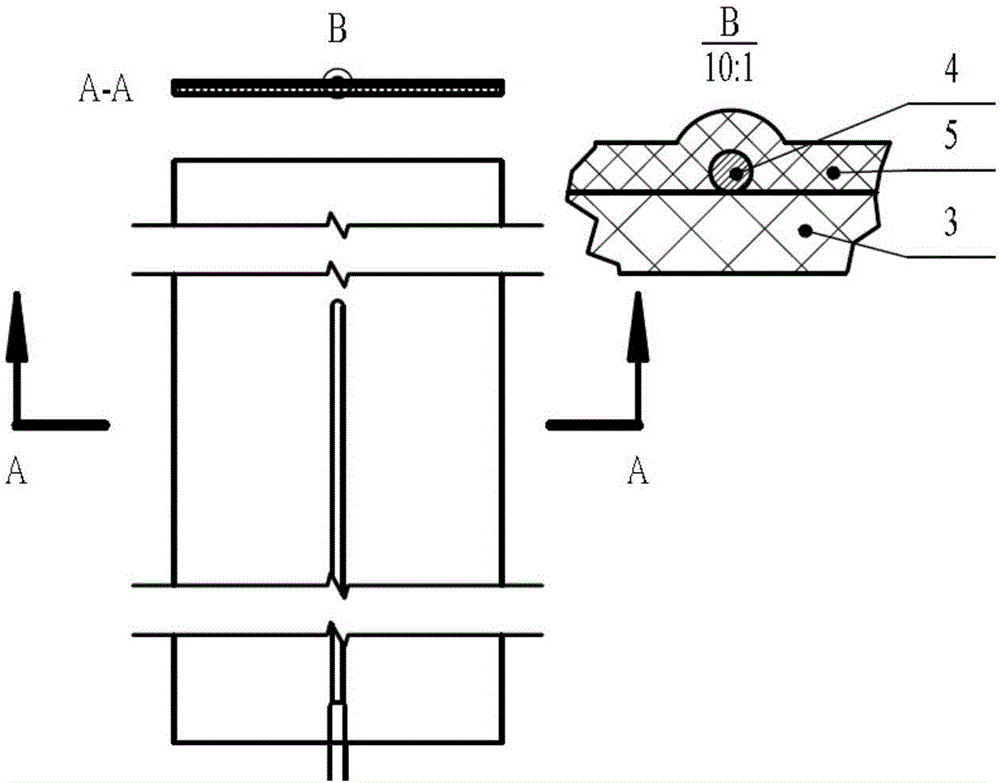

[0045] A glass fiber / epoxy resin composite substrate type fiber grating sensor, its structure is as follows Figure 1a , Figure 1b and figure 2 As shown, it includes: a glass fiber / epoxy resin composite material substrate 3; an optical fiber grating 4 loaded on the upper surface of the glass fiber / epoxy resin composite material substrate 3; and a dry glass fiber cloth 5 covered above the optical fiber grating 4;

[0046] The dry glass fiber cloth 5 is infiltrated with the liquid epoxy resin assisted by vacuum infusion, and the liquid epoxy resin is poured between the dry glass fiber cloth 5 and the glass fiber / epoxy resin composite material substrate 3, and the cohesion in the cured resin is The valence bonds are firmly combined to form a complete fiber grating sensor.

[0047] Specifically:

[0048] The glass fiber / epoxy resin composite substrate 3 is located at the bottom of the entire fiber grating sensor, its upper surface is used to load the fiber grating 4, and its l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com