Graphene pressure sensor array system and preparation method thereof

A pressure sensor and graphene technology, applied in the measurement of the property and force of piezoelectric resistance materials, etc., can solve the problems of unfavorable wide application, complex process, graphene pressure sensor cannot be used for monitoring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

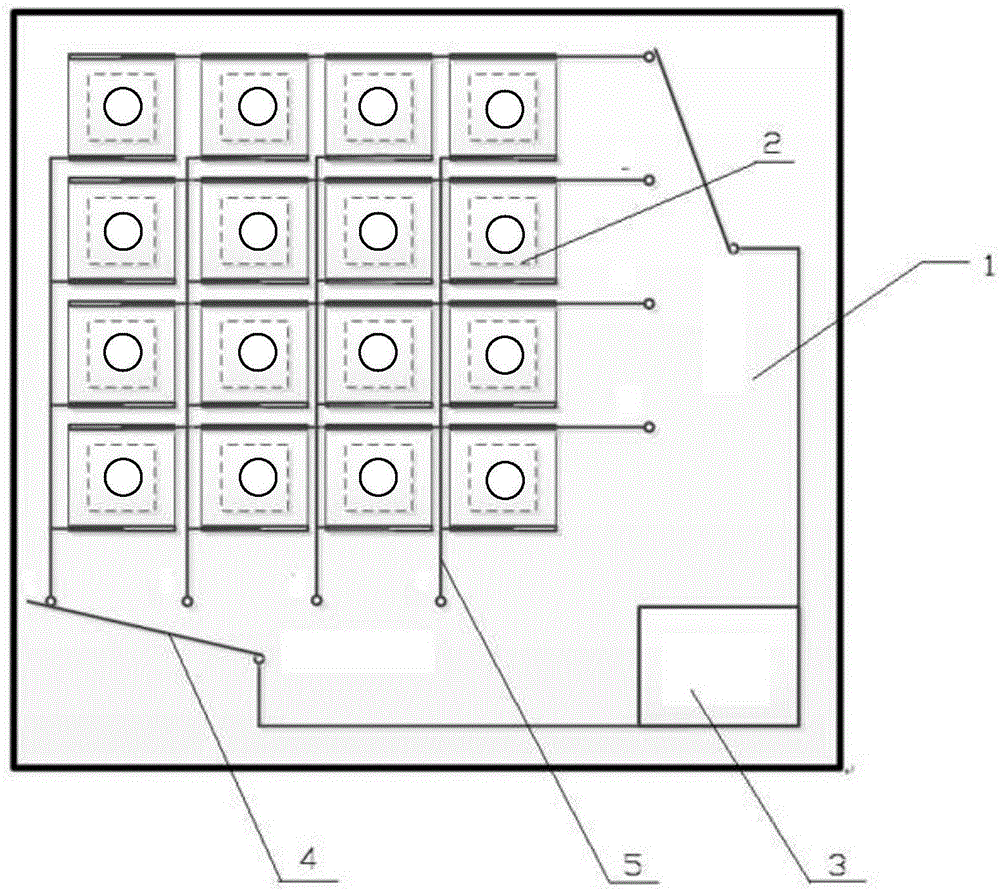

[0039] Embodiment 1 provides a kind of method for preparing graphene pressure sensor array system, and its array is 4 * 4, comprises the following steps:

[0040] Step 1. Engraving several grooves on the array circuit board; engrave a 4×4 groove area array of 0.5mm×0.5mm in size on the upper layer of the rigid circuit board by laser cutting, with an interval of 0.5mm.

[0041] Step 2. Arrange the array circuit on the array circuit board with grooves carved; make the array circuit on the rigid circuit board, the line width is 0.1mm, and correspond to the hollowed out area; the array circuit includes warp (vertical circuit) and weft (horizontal circuit) ), the circuit formed is used to connect the electrodes at both ends of each sensor unit, and controls the gating of the unit device through an analog switch.

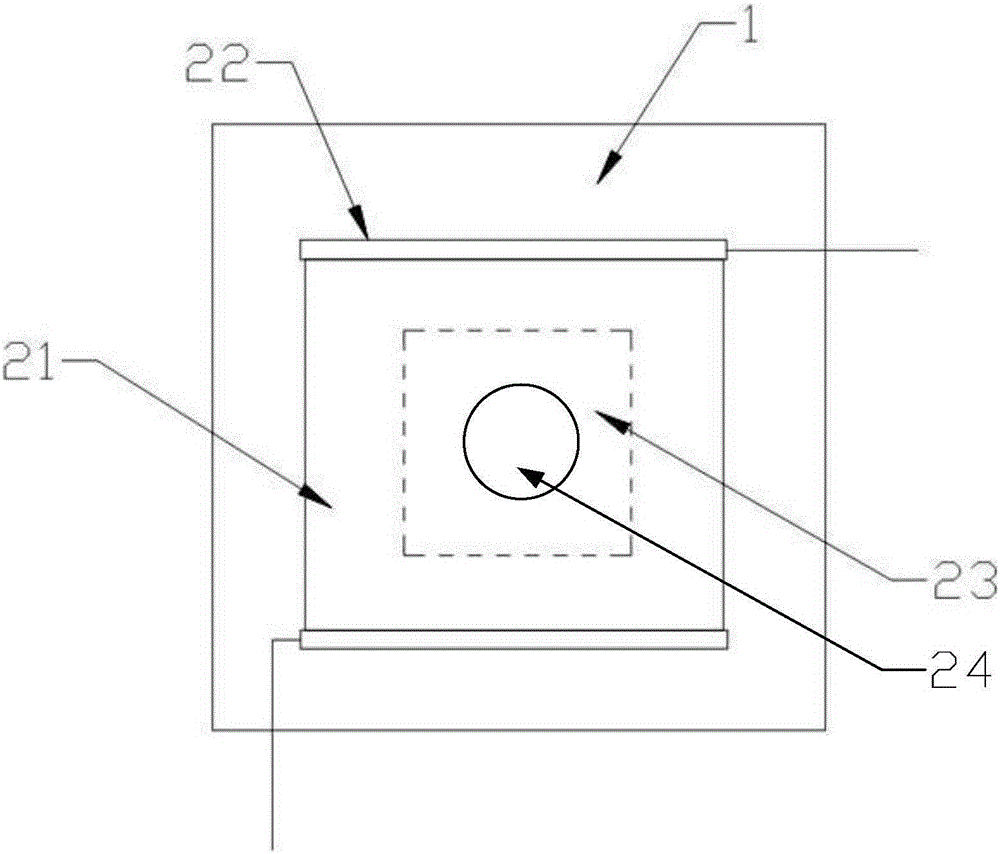

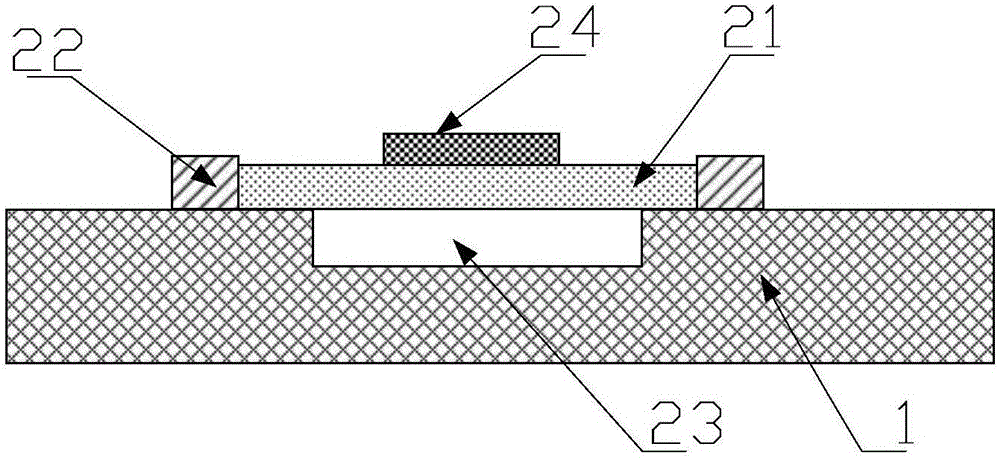

[0042] Step 3. Make a force-sensitive film composed of a graphene layer and a polymer layer. The steps are as Figure 4 Shown, have the following steps again.

[0043]...

Embodiment 2

[0050] Embodiment 2 provides a kind of method for preparing graphene pressure sensor array system, and its array is 9 * 8, comprises the following steps:

[0051] Step 1. Carve a number of grooves on the array circuit board; engrave a 9×8 groove area array of 3.2mm×3.2mm in size on the upper layer of the flexible circuit board by laser cutting, with an interval of 0.8mm.

[0052] Step 2. Arrange the array circuit on the array circuit board with grooves engraved; make the array circuit on the rigid circuit board, the line width is 0.1mm, and correspond to the hollowed out area; the array circuit includes warp (vertical circuit) and weft (horizontal circuit) circuit), the circuit formed is used to connect the two ends of each sensor unit, and controls the gating of the unit device through an analog switch.

[0053] Step 3. make the force-sensitive film that graphene layer and polymer layer are compounded; This step is as follows Figure 5 Shown, have the following steps again. ...

Embodiment 3

[0061] Embodiment 3 provides a kind of method for preparing graphene pressure sensor array system, and its array is 100 * 100, comprises the following steps:

[0062] Step 1. Carve a number of grooves on the array circuit board; engrave an array of 100×100 groove areas with a size of 18mm×18mm on the upper layer of the flexible circuit board by laser cutting, with an interval of 2mm.

[0063] Step 2. Arrange the array circuit on the array circuit board with grooves engraved; make the array circuit on the rigid circuit board, the line width is 0.1mm, and correspond to the hollowed out area; the array circuit includes warp (vertical circuit) and weft (horizontal circuit) circuit), the circuit formed is used to connect the two ends of each sensor unit, and controls the gating of the unit device through an analog switch.

[0064] Step 3. make the force-sensitive film that graphene powder and polymer are compounded; This step is as follows Figure 5 Shown, have the following steps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com