Device and method for measuring rotating speed of rotating shaft based on variable density sine fringe

A technology for measuring sinusoidal fringes and rotating speed, which is applied to measuring devices, devices using optical methods, radio wave measuring systems, etc., can solve the problems of increased burden on the acquisition system, achieve increased computing speed, reduced sampled data, and improved image transmission Effect of Rate and System Sampling Frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

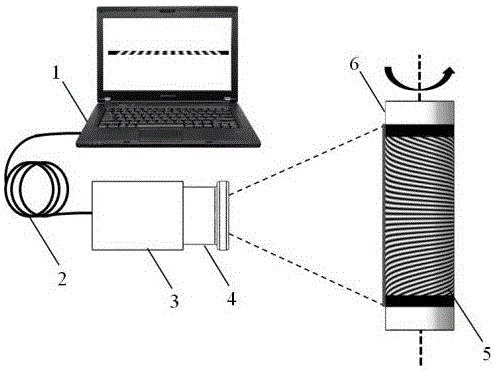

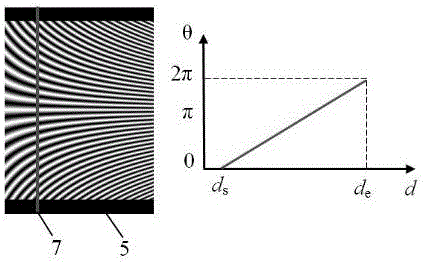

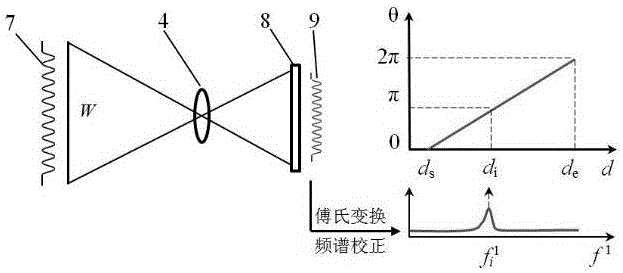

[0043] figure 1 It is a schematic diagram of the device structure of the embodiment of the present invention. like figure 1 As shown, this embodiment provides a rotating shaft rotational speed measurement device based on variable density sinusoidal fringes, including a variable density sinusoidal fringe sensor 5, a high-speed image acquisition module 3, a data transmission module 2, a computer 1, an image processing software module and the measured rotating shaft 6. The variable density sinusoidal fringe sensor 5 is arranged on the circumferential surface of the rotating shaft 6 to be measured, and is used for encoding the rotation angle information of the rotating shaft 6 to be measured. The high-speed image acquisition module 3 is used for continuous imaging and recording of the variable-density sinusoidal fringe sensor 5 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com