Phase type liquid crystal grating with electrically-controlled continuous tuning diffraction spot positions and manufacturing method of phase type liquid crystal grating

A liquid crystal grating and phase type technology, applied in the grating field, can solve the problems of low diffraction efficiency and high driving voltage, and achieve the effect of mature technology, low driving voltage and compatible manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing:

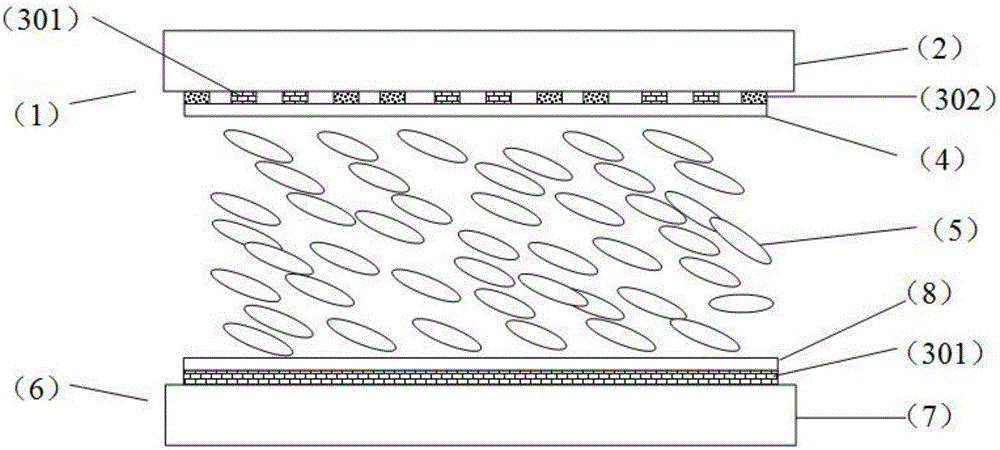

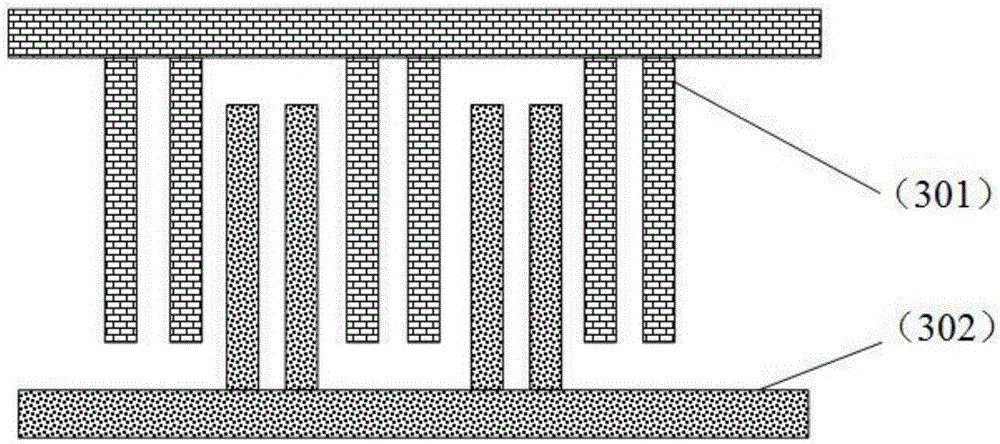

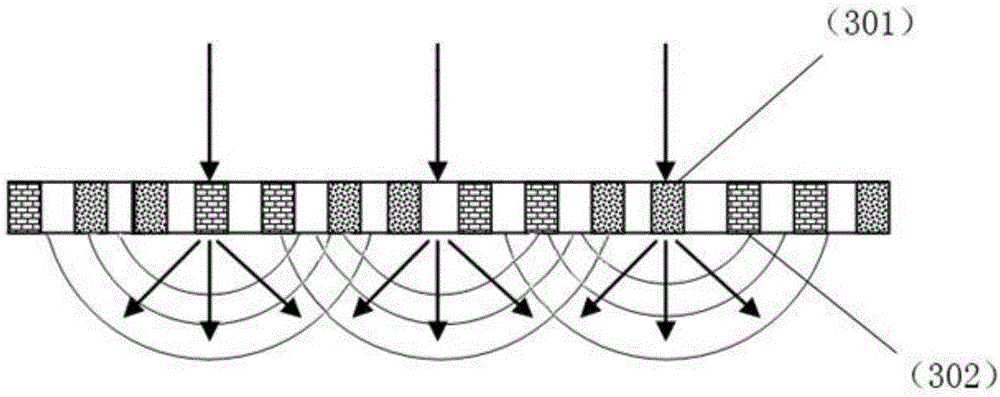

[0015] The invention provides an electronically controlled phase type liquid crystal grating for continuously tuning the position of a diffraction spot and a manufacturing method thereof, and relates to the technical field of gratings. The invention includes an upper substrate, a lower substrate and a liquid crystal which are arranged oppositely. The upper substrate includes an upper substrate glass, a comb-shaped electrode layer, and an upper alignment layer arranged in sequence, and the lower substrate includes a lower substrate glass, a comb-shaped electrode layer, and a lower alignment layer. A nematic liquid crystal layer is contained between the upper alignment layer and the lower alignment layer of the substrate. The present invention can control the continuous deflection of the liquid crystal molecules by continuously changing the voltage of the comb electrode, and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com