Preparation and application of lithium-sulfur battery positive electrode composite material

A technology of lithium-sulfur batteries and composite materials, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., to achieve the effects of good battery cycle performance, good cycle stability, and novel substrate materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing a lithium-sulfur battery cathode composite material, specifically comprising the steps of:

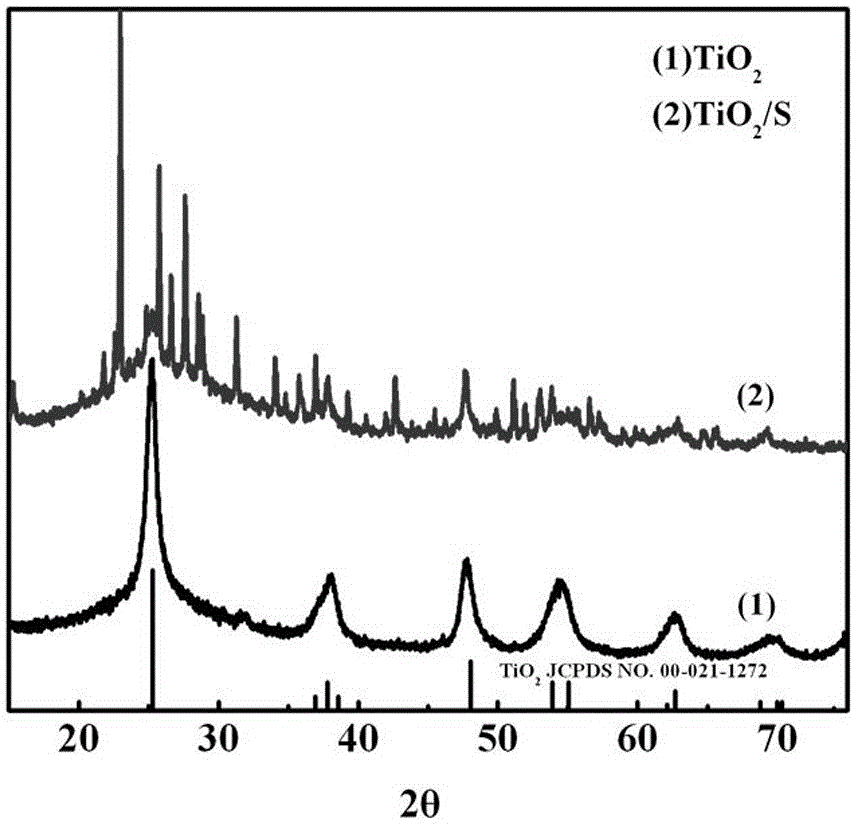

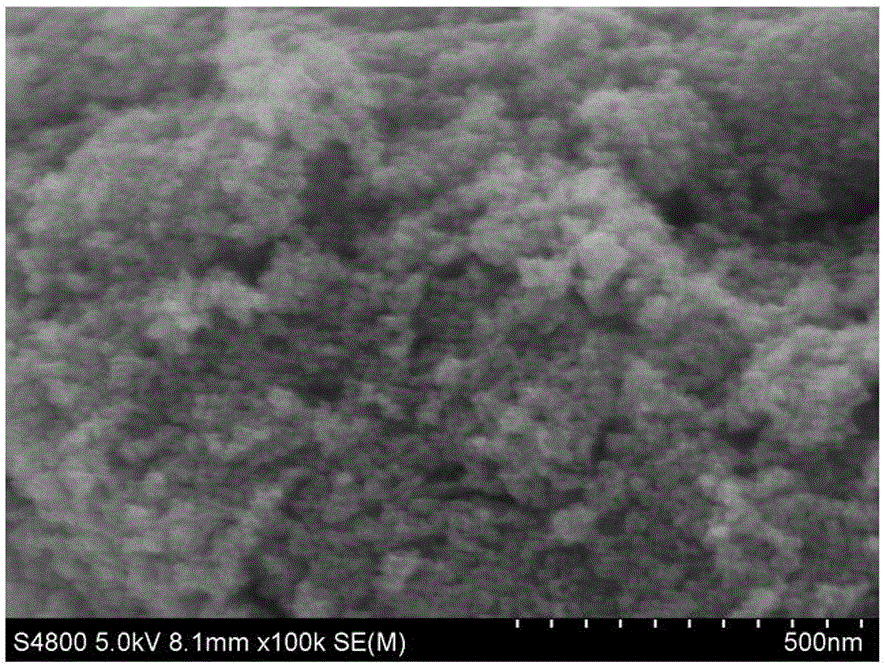

[0022] (1) 0.5 g anatase TiO 2 The powder was dispersed in 50 mL of 15M KOH solution, stirred for 10 minutes and then transferred to a 75 ml polytetrafluoroethylene-lined autoclave at 180 o C for 72 hours, the resulting precipitate was subjected to 0.1 M H 2 SO 4 The solution was washed several times to pH 1-2, and centrifuged, and then at 70 o Dry in C air for 12 hours to get titanate nanowires;

[0023] (2) Disperse 200 mg of titanate nanowires in 1 M H 2 SO 4 solution, at 70 o C, heated and stirred in a water bath for 7 days, and the white precipitate obtained after natural cooling was washed several times with deionized water, then centrifuged and separated, and then placed in the air for 70 o C dried for 12 hours to obtain anatase phase TiO 2 mesomorph;

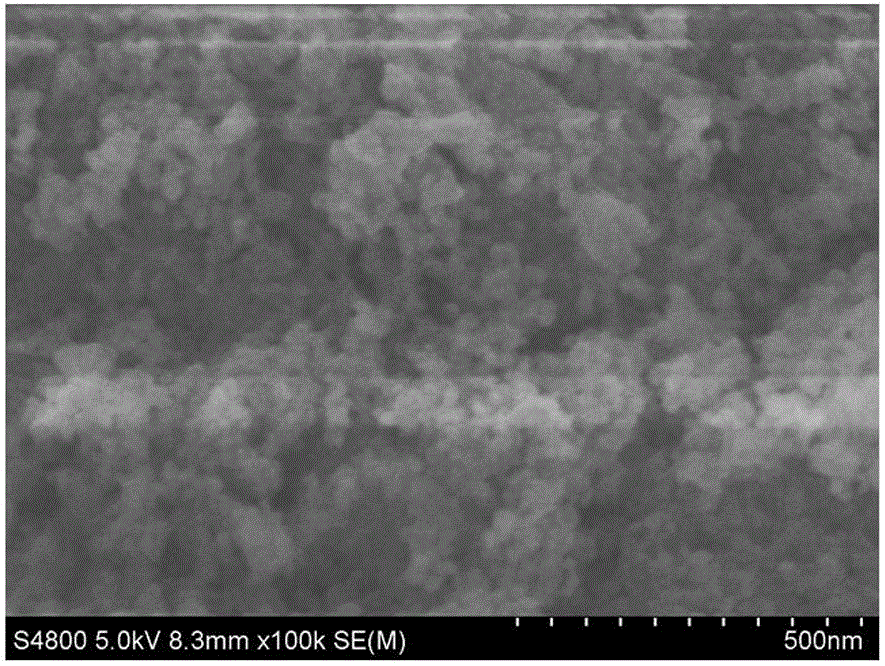

[0024] (3) TiO 2 After compound grinding of mesogen and elemental sulfur at a mass ra...

Embodiment 2

[0028] A method for preparing a lithium-sulfur battery cathode composite material, specifically comprising the steps of:

[0029] (1) Add 0.8g anatase TiO 2 The powder was dispersed in 80 mL of 15M KOH solution, stirred for 12 minutes and then transferred to a 90 ml polytetrafluoroethylene-lined autoclave at 150 o C for 80 hours, the resulting precipitate was subjected to 0.1 M H 2 SO 4 The solution was washed several times to pH 1-2, and centrifuged, and then o Dry in C air for 14 hours to obtain titanate nanowires;

[0030] (2) Disperse 200 mg of titanate nanowires in 1 M H 2 SO 4 solution, at 60 o C, heated and stirred in a water bath for 7 days, and the white precipitate obtained after natural cooling was washed several times with deionized water, then centrifuged and separated, and then placed in the air for 60 o C dried for 14 hours to obtain anatase phase TiO 2 mesomorph;

[0031] (3) TiO 2 After compound grinding of mesogen and elemental sulfur at a mass ra...

Embodiment 3

[0034] A method for preparing a lithium-sulfur battery cathode composite material, specifically comprising the steps of:

[0035] (1) Add 1.0g anatase TiO 2 The powder was dispersed in 100mL of 15M KOH solution, stirred for 15 minutes, then transferred to an autoclave with 100 ml of polytetrafluoroethylene lining, at 200 o C for 84 hours, the resulting precipitate was subjected to 0.1 M H 2 SO 4 The solution was washed several times until the pH reached 1-2, and was separated by centrifugation, and then at 80 o Dry in C air for 16 hours to obtain titanate nanowires;

[0036] (2) Disperse titanate nanowires in 1 M H 2 SO 4 solution, at 80 o C, heated and stirred in a water bath for 8 days, and the white precipitate obtained after natural cooling was washed several times with deionized water, then centrifuged and separated, and then placed in the air for 80 o C dried for 16 hours to obtain anatase phase TiO 2 mesomorph;

[0037] (3) TiO 2 After compound grinding of mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com