Nickel cobalt lithium manganate material and preparation method thereof

A technology of nickel-cobalt lithium manganese oxide and nickel-cobalt-manganese hydroxide, which is applied in the field of preparation of lithium-ion battery cathode materials, can solve the problems of high labor intensity, long reaction process steps, and unautomatic control of the reaction process, achieving excellent safety Performance, high temperature performance long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 The mixture described in this example is also a mixture of nickel hydroxide, cobalt manganese and lithium carbonate. The mixture is packed in a sagger, that is, in the bowl, and the inside of the sagger is in the bowl, the same below.

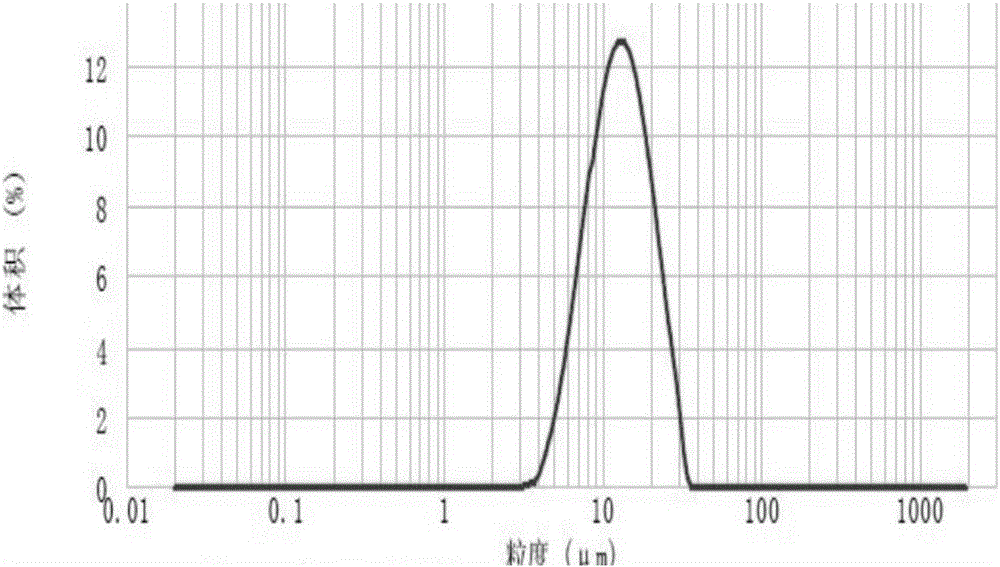

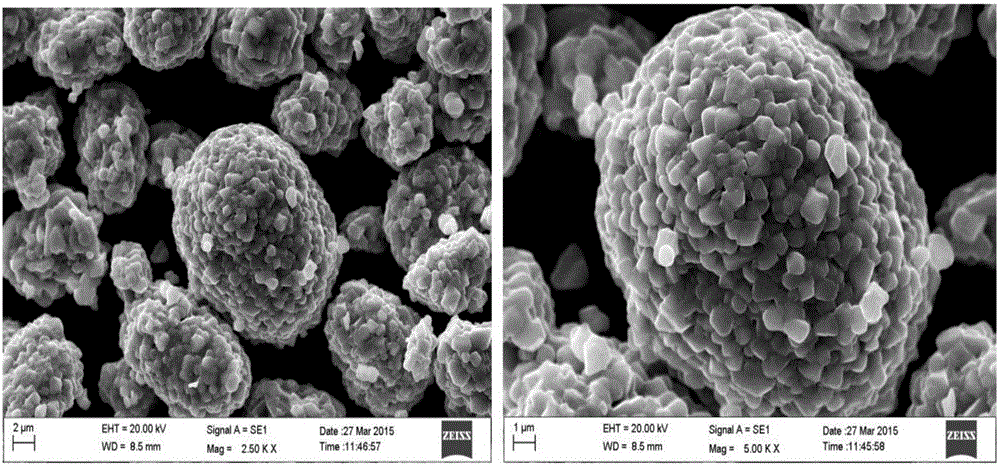

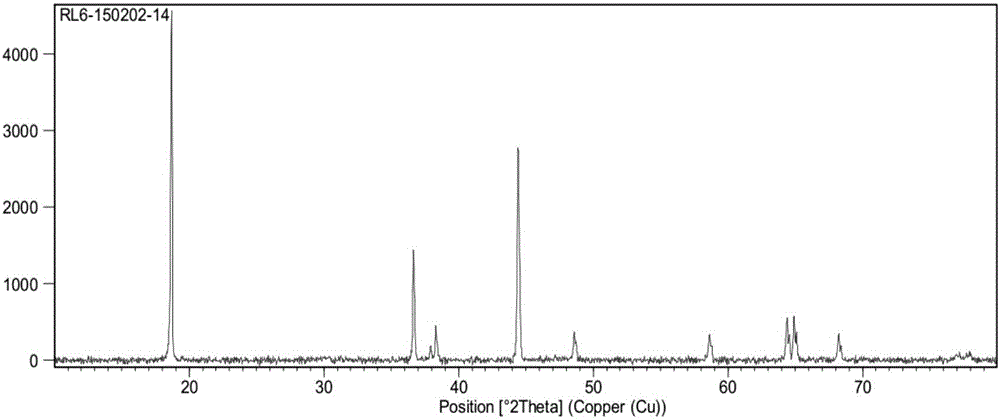

[0032] The present embodiment 1 adopts the method of the present invention to prepare a kind of nickel-cobalt lithium manganate material, and the stoichiometric ratio of nickel-cobalt-manganese of this material is 8:1:1, and chemical formula is LiNi 0.8 co 0.1 mn 0.1 o 2 , with soluble nickel, cobalt, and manganese salts as raw materials, the specific process steps are as follows, 1) Co-precipitation reaction to prepare the precursor of nickel-cobalt lithium manganese oxide, using soluble nickel, cobalt sulfate, and manganese chloride as raw materials, and adding water to make it separately The mixed aqueous solution of nickel, cobalt and manganese salts is added with sodium hydroxide aqueous solution as a precipitating agent...

Embodiment 2

[0047] The product LiNi that present embodiment 2 prepares 0.5 co 0.2 mn 0.3 o 2 The performances described for it are shown in Table 1, and the molecular formula of its prepared product is nickel cobalt lithium manganate material LiNi 0.5 co 0.2 mn 0.3 o 2 , the stoichiometric ratio of controlling nickel-cobalt-manganese is 5:2:3, and its preparation method and steps are implemented with step 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com