Power battery module with disaster prevention system

A technology for power batteries and battery modules, applied to battery pack components, secondary batteries, circuits, etc., can solve problems such as easy temperature rise, temperature imbalance, internal short circuit of the battery, etc., and achieve long cycle life, light weight and durability , Realize the effect of battery disaster prevention and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

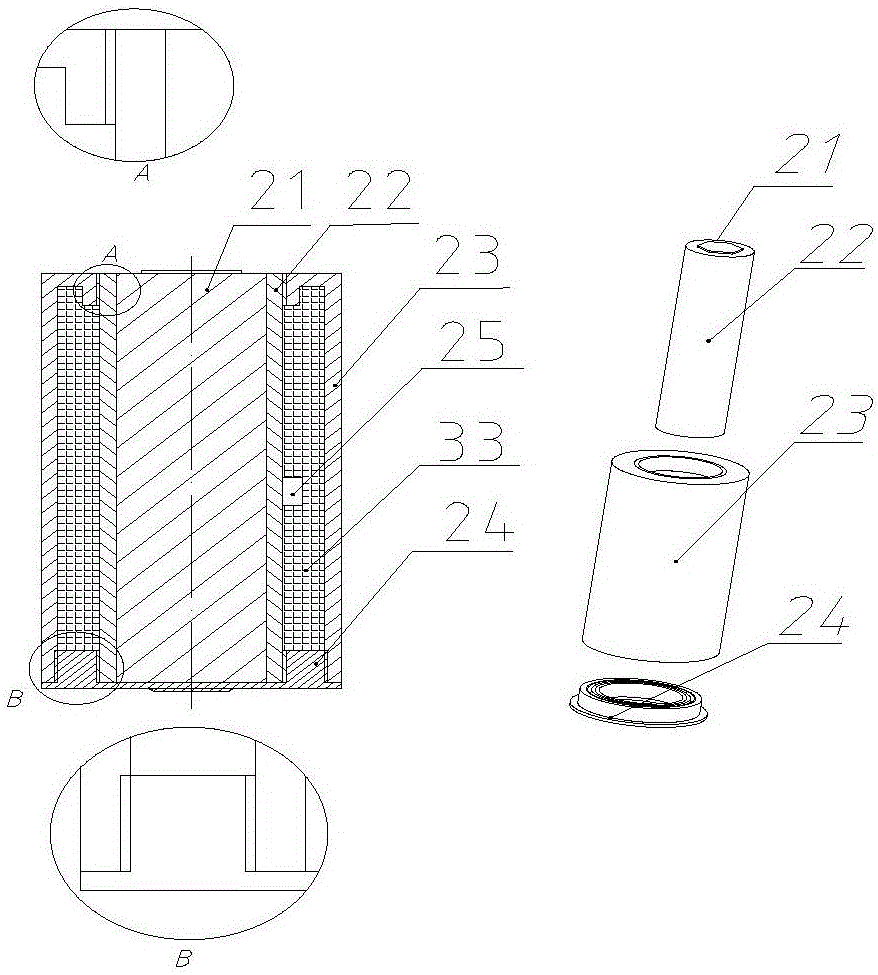

[0028] The present invention fills the phase change material between the frame body and the battery unit, first stores heat through the phase change material, performs heat buffering, and then conducts heat exchange with the external environment through the ventilation channel to achieve the purpose of heat dissipation. The glass fiber that can withstand the external pressure, the shell made of carbon fiber and the phase change material act as a pressure buffer during the acupuncture test and the collision test. The phase change material is integrated with the battery cell, which can enable the power battery to achieve the optimal temperature in an extremely harsh environment, and can maintain the temperature balance of the battery cell.

[0029] Carry out following specific description for the embodiment of the present invention:

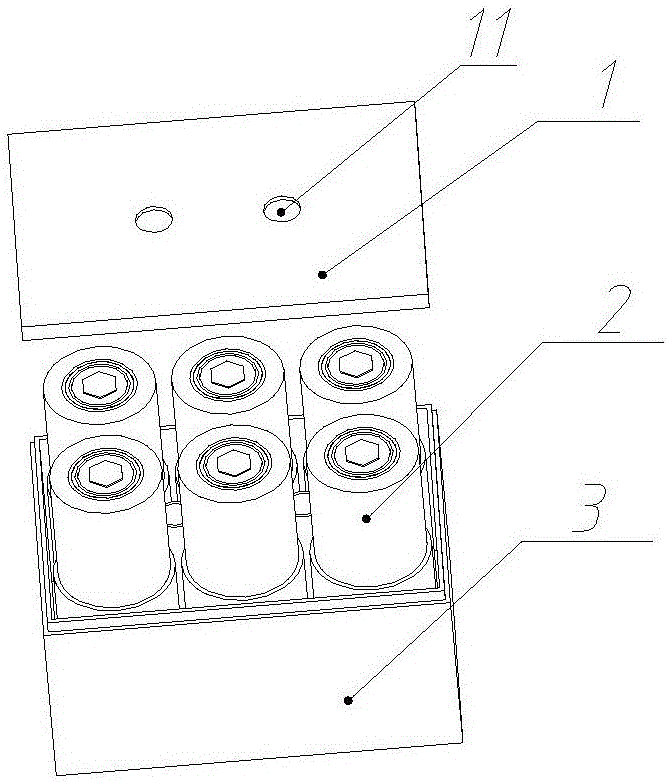

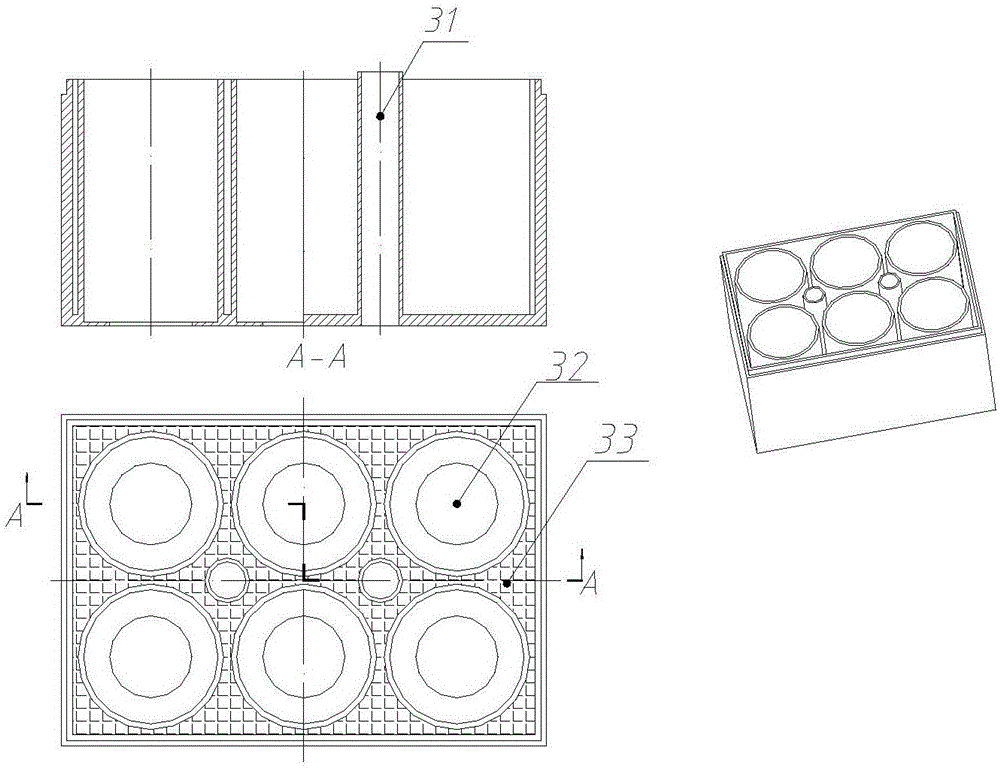

[0030] figure 1 It is an overall view of the power battery with the disaster prevention system of the present invention. figure 2 It is a plan ...

Embodiment 2

[0040]The battery acupuncture testing machine is used, product model: GT-BT-3104, and the relevant parameters of the battery acupuncture testing machine are as follows: ①High temperature-resistant steel needle of Φ2~8mm; ②The distance between the needle tip and the lower part: the plane where the battery is placed is 150mm; 150MM; ④At a speed of 10-40mm / s, penetrate from the direction perpendicular to the battery plate (the steel needle stays in the battery); ⑤The penetration force is 150-200KG; ⑥The stroke is 150mm. Experiments were carried out according to the parameters of the acupuncture testing machine mentioned above. A steel needle with a diameter of Φ2-8mm vertically penetrated a single battery with a phase change material inside at a speed of 30mm / s and a penetration force of 180KG. The test results show that the temperature of the battery rises rapidly to 150°C in the early stage of needle penetration, but drops rapidly to 30°C. The results show that this is due to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com