Prefabricated intelligent traction substation

A traction substation, prefabricated technology, applied in distribution substation, substation/distribution device housing, substation/switch layout details, etc., can solve the problems of signal transmission interference, long construction period of substation, long construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

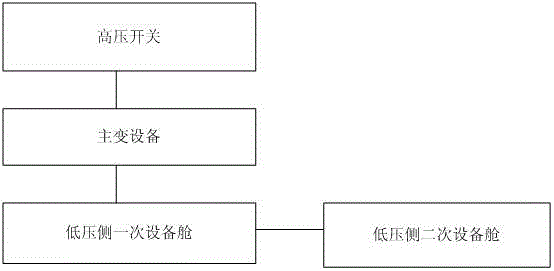

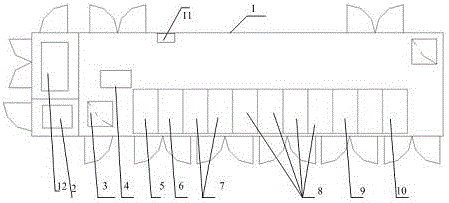

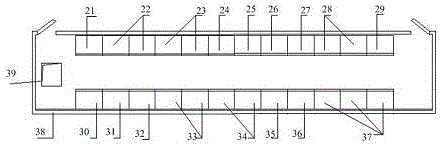

[0025] Such as Figure 1-Figure 3 As shown, the pre-installed intelligent traction substation includes high-voltage switches connected to the high-voltage network, main transformer equipment connected to the high-voltage switches for transformation, low-voltage side primary equipment connected to the main transformer equipment, and protection, measurement and control low-voltage side primary equipment Low-voltage side secondary equipment, of which the low-voltage side primary equipment is integrated in the low-voltage side primary equipment compartment 1, the low-voltage side secondary equipment is integrated in the low-voltage side secondary equipment compartment 38, the low-voltage side primary equipment compartment 1 and the low-voltage side secondary equipment compartment The equipment cabin 38 adopts a prefabricated cabin structure made of non-metallic high-corrosion composite materials. The low-voltage side primary equipment cabin 1 and the low-voltage side secondary equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com