Method for continuously producing 5-chlorine-2-pentanone

A pentanone and production system technology, applied in chemical instruments and methods, preparation of organic compounds, carbon-based compounds, etc., can solve the problems of poor economy of chlorine atoms, unstable product quality, difficult post-processing, etc., and achieve product The effect of stable quality, escape prevention and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

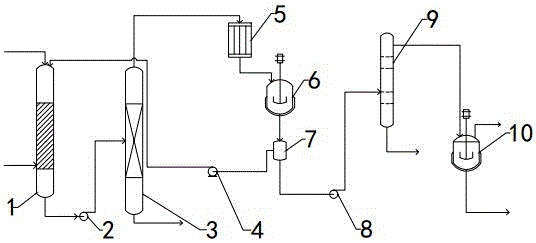

[0021] The used reactor 1 of the chlorination reaction operation is a tower reactor or a tank reactor with a steaming column; hydrogen chloride gas enters from the bottom of the reactor 1 at a speed of 38kg / h, and 2000kg3-acetylpropanol enters at the bottom of the reactor 1 at a rate of 200kg / h. The speed enters from the top of the reactor 1, the reaction temperature in the reactor 1 is 50°C, the reaction pressure is 0.4MPa, and the material mixing reaction time is 172min; after the materials are fully mixed and reacted, the material at the bottom of the reactor 1 is transported into the azeotropic distillation tower 3 ;

[0022] In the azeotropic distillation process, the mixture containing material and water from the reactor 1 is distilled through the azeotropic distillation tower 3; The distillate enters the water separation tank 7 after being condensed by the condenser 5 to carry out the oil-water phase process, and the aqueous solution rich in hydrogen chloride in the upp...

Embodiment 2

[0025] The used reactor 1 of the chlorination reaction operation is a tower reactor or a tank reactor with a steaming column; hydrogen chloride gas enters from the bottom of the reactor 1 at a speed of 38kg / h, and 2000kg3-acetylpropanol enters at the bottom of the reactor 1 at a rate of 200kg / h. The speed enters from the top of the reactor 1, the reaction temperature in the reactor 1 is 52°C, the reaction pressure is 0.35MPa, and the material mixing reaction time is 176min; after the materials are fully mixed and reacted, the material at the bottom of the reactor 1 is transported into the azeotropic distillation tower 3 ;

[0026] In the azeotropic distillation process, the mixture containing material and water from the reactor 1 is distilled through the azeotropic distillation tower 3; The distillate enters the water separation tank 7 after being condensed by the condenser 5 to carry out the oil-water phase process, and the aqueous solution rich in hydrogen chloride in the up...

Embodiment 3

[0029]The used reactor 1 of the chlorination reaction operation is a tower reactor or a tank reactor with a steaming column; hydrogen chloride gas enters from the bottom of the reactor 1 at a speed of 38kg / h, and 2000kg3-acetylpropanol enters at the bottom of the reactor 1 at a rate of 200kg / h. The speed enters from the top of the reactor 1, the reaction temperature in the reactor 1 is 49°C, the reaction pressure is 0.45MPa, and the material mixing reaction time is 168min; after the materials are fully mixed and reacted, the material at the bottom of the reactor 1 is transported into the azeotropic distillation tower 3 ;

[0030] In the azeotropic distillation process, the mixture containing material and water from the reactor 1 is distilled through the azeotropic distillation tower 3; The distillate enters the water separation tank 7 after being condensed by the condenser 5 to carry out the oil-water phase process, and the aqueous solution rich in hydrogen chloride in the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com