Centrifugal dewatering type potato cleaning device with cutting treatment function

A centrifugal dehydration and cleaning device technology, applied in food processing, application, metal processing, etc., can solve the problems of inconvenient maintenance, etc., and achieve the effect of convenient operation, convenient operation, simple structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

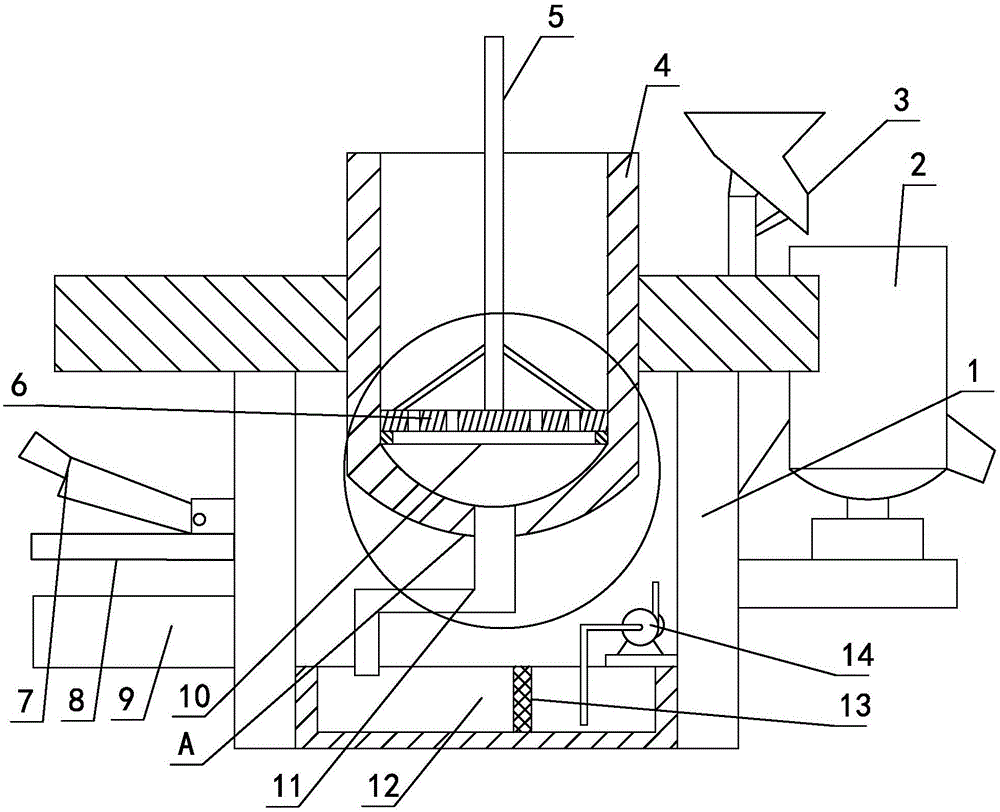

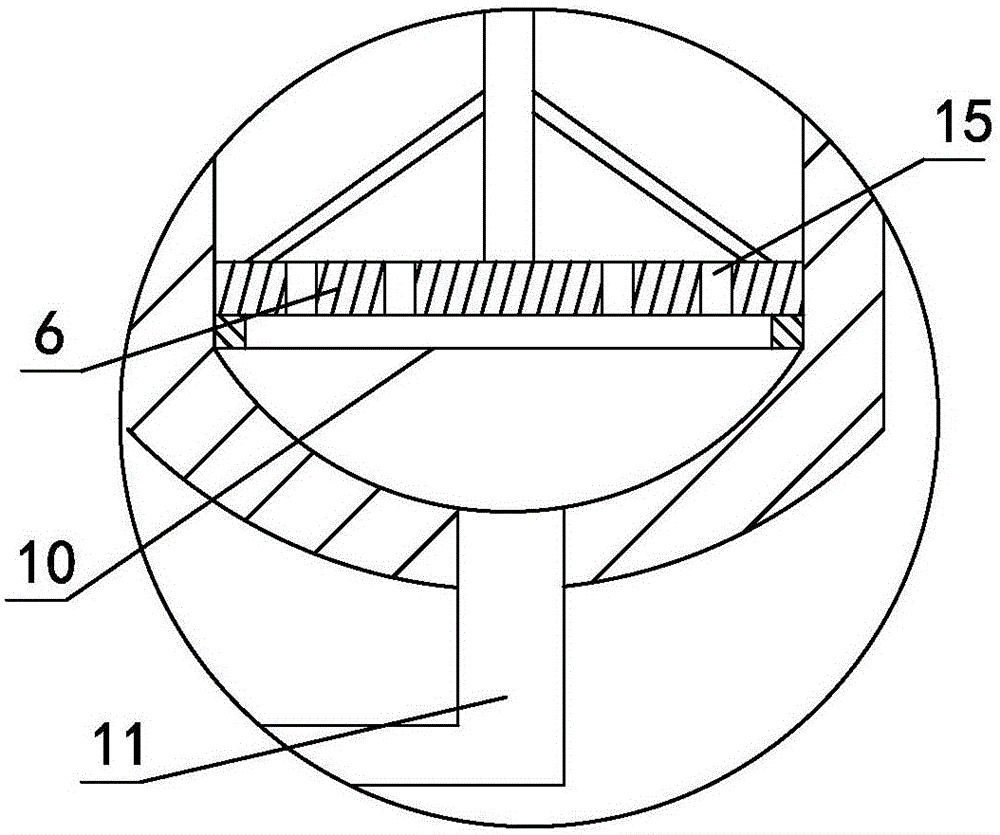

[0026] like figure 1 , figure 2 As shown, the centrifugal dehydration potato cleaning device with cutting process includes a workbench 1, on which a cleaning bucket 4 is vertically installed, and the bottom of the cleaning bucket 4 is provided with a drainage pipeline 11, and the horizontal in the cleaning bucket 4 A lifting plate 6 that moves up and down is provided, and the top of the lifting plate 6 is provided with a lifting rod 5 for moving the lifting plate 6 up and down. Several drainage holes 15 are provided on the lifting plate 6, and the drain end of the drainage pipeline 11 is provided with waste water. The processing mechanism is horizontally provided with a cutting knife 7 and a cutting plate 8 for mutual cutting and matching on the lower left half of the workbench 1, a waste collection tank 9 is arranged on the workbench 1 below the cutting plate 8, and a waste collection tank 9 is arranged on the workbench on the right side of the cleaning bucket 4. 1 is verti...

Embodiment 2

[0031] On the basis of Embodiment 1, the gap between the lifting plate 6 and the cleaning bucket 4 is changed to 20mm; the diameter of the drainage hole 15 is changed to 30mm; the power mechanism includes a hoist, and the hoist is installed through a bracket Above the workbench 1, the rope of the winch is connected with the lifting rod 5.

[0032] Others are the same as embodiment one.

Embodiment 3

[0034] On the basis of the first embodiment, the gap between the lifting plate 6 and the cleaning bucket 4 is changed to 15mm; the diameter of the drainage hole 15 is changed to 20mm.

[0035] Others are the same as embodiment one.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap