Blank high-molecular microspheres and preparation method thereof

A technology of polymer microspheres and polymer carriers, which is applied in the direction of non-active components of polymer compounds, medical preparations of non-effective components, and pharmaceutical formulas, and can solve problems such as complex production conditions and difficulty in large-scale production. Simple, high repeatability, well-defined effect of microsphere structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1300

[0023] Embodiment 1 makes blank PEG-PLA microspheres with 300gPEG-PLA (molecular weight 150,000)

[0024] The preparation steps of the blank PEG-PLA microspheres: Take 300g of PEG-PLA and dissolve it in 1000ml of dichloromethane, spray dry it with a spray dryer, the inlet temperature is 40°C, the feed rate is 100ml / h, the atomization pressure is 0.1KPa, the power is 40Hz, Prepare blank PLGA microspheres.

Embodiment 2

[0025] Example 2 Prepare blank PLA microspheres with 100g PLA (molecular weight: 700,000).

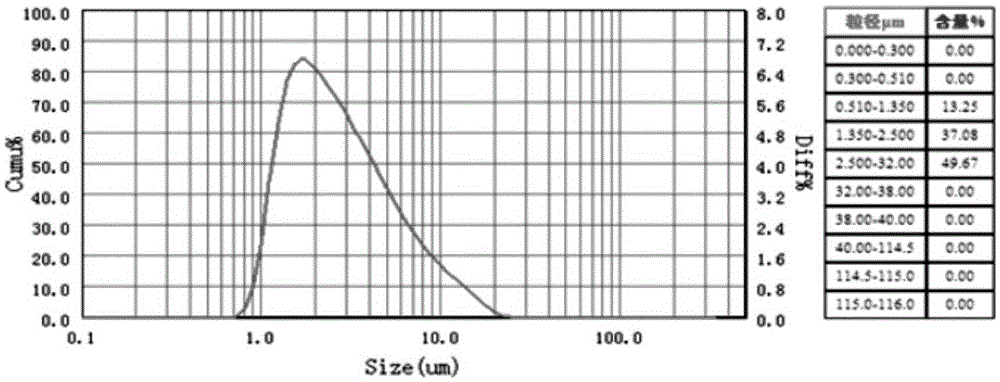

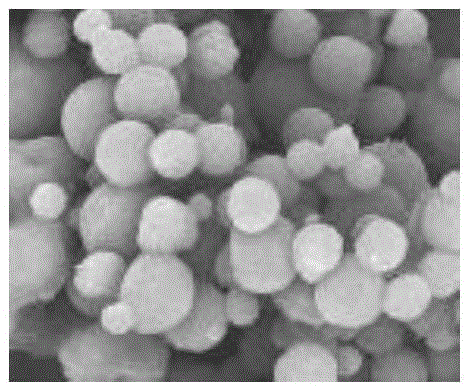

[0026] The preparation steps of the blank PLA microspheres: PLA (100g) was dissolved in 20L ethyl acetate, spray-dried using a spray dryer, the inlet temperature was 70°C, the feed rate was 1000ml / h, the atomization pressure was 0.4KPa, and the power was 15Hz. Blank PLA microspheres. (Refer to the morphology under SEM figure 1 , see particle size diagram figure 2 )

Embodiment 3

[0027] Example 3 Blank silk fibroin microspheres were prepared with 100 g of silk fibroin.

[0028] The preparation steps of the blank silk fibroin microspheres are as follows: dissolve silk fibroin in 100ml of purified water, use a spray dryer to spray dry, the inlet temperature is 200°C, the feed rate is 700ml / h, the atomization pressure is 0.3KPa, and the power is 20Hz. Blank silk fibroin microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com