Magnetic powdered activated carbon adsorbent and preparation method and application thereof

A technology of powder activated carbon and adsorbent, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxide/hydroxide, etc., can solve the problem of insufficient adsorption capacity, achieve effective desorption regeneration, and facilitate separation , the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

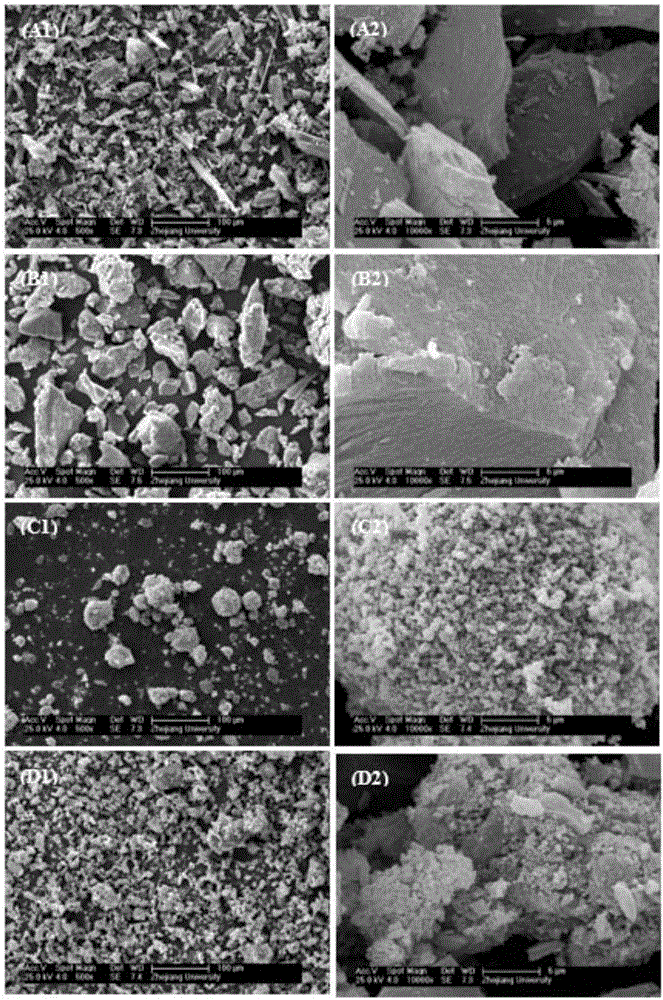

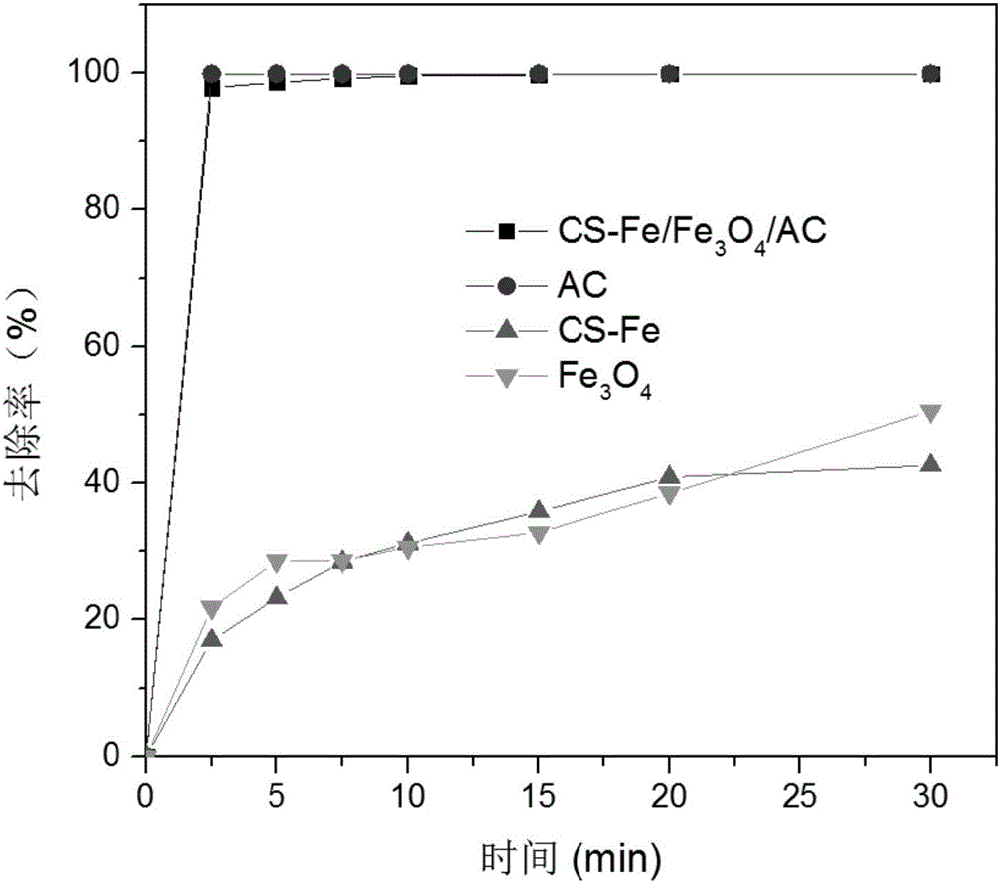

[0034] Add 100mL of deionized water into a 250mL beaker, add 1.352g of hexahydrate and ferric chloride, stir until completely dissolved with an electromagnetic stirrer, slowly add 2g of chitosan, and continue stirring for 2 hours to make chitosan and Fe 3+ Fully react, then add a certain amount of powdered activated carbon and Fe according to the data in Table 1 3 o 4 , continue stirring for 2 hours. Use a magnet to separate the precipitate and supernatant, wash the precipitate 4 times with deionized water, dry it in an oven at 80°C, and grind it a little to obtain Examples 1-3, which are recorded as CS-Fe / Fe 3 o 4 / AC.

[0035] The preparation conditions of table 1 embodiment 1~7

[0036] Example The amount of activated carbon added (g) Join Fe 3 o 4 Amount (g)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com