Low-temperature hole-making device and method for fiber composite material and metal laminated structure

A technology of fiber composite materials and metal lamination, which is applied in the direction of metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of low processing efficiency of devices, and achieve the improvement of hole making efficiency, increase of material brittleness, cutting tools Effect of life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

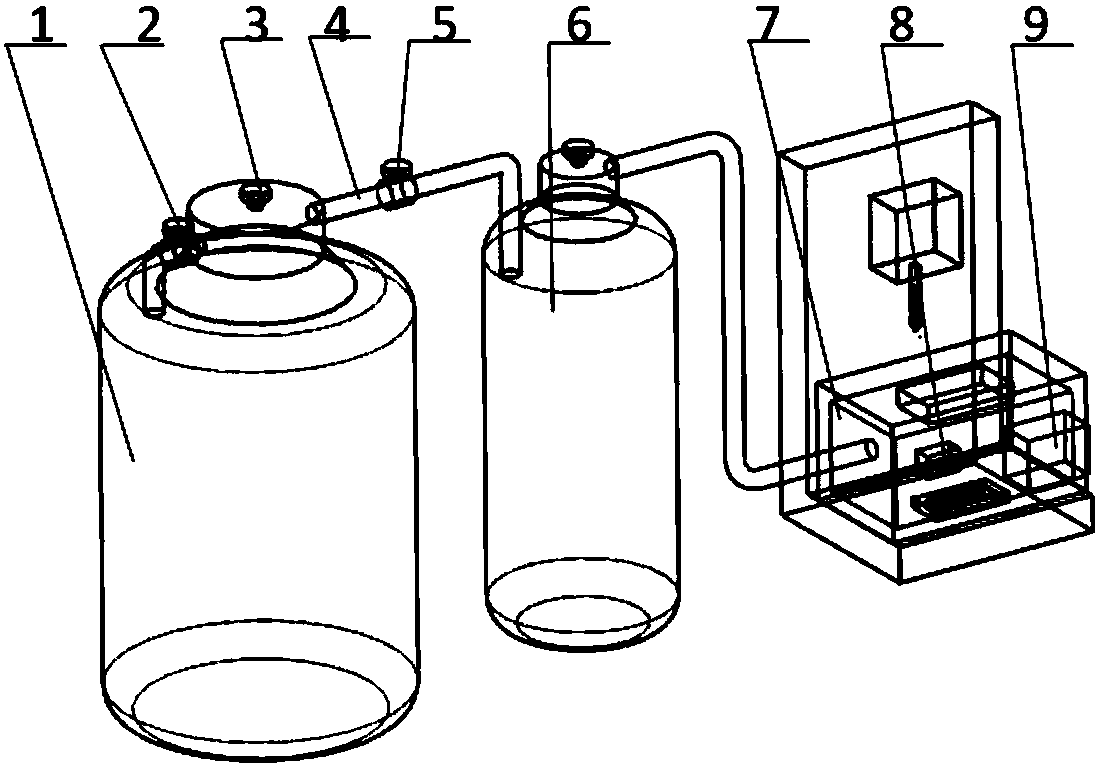

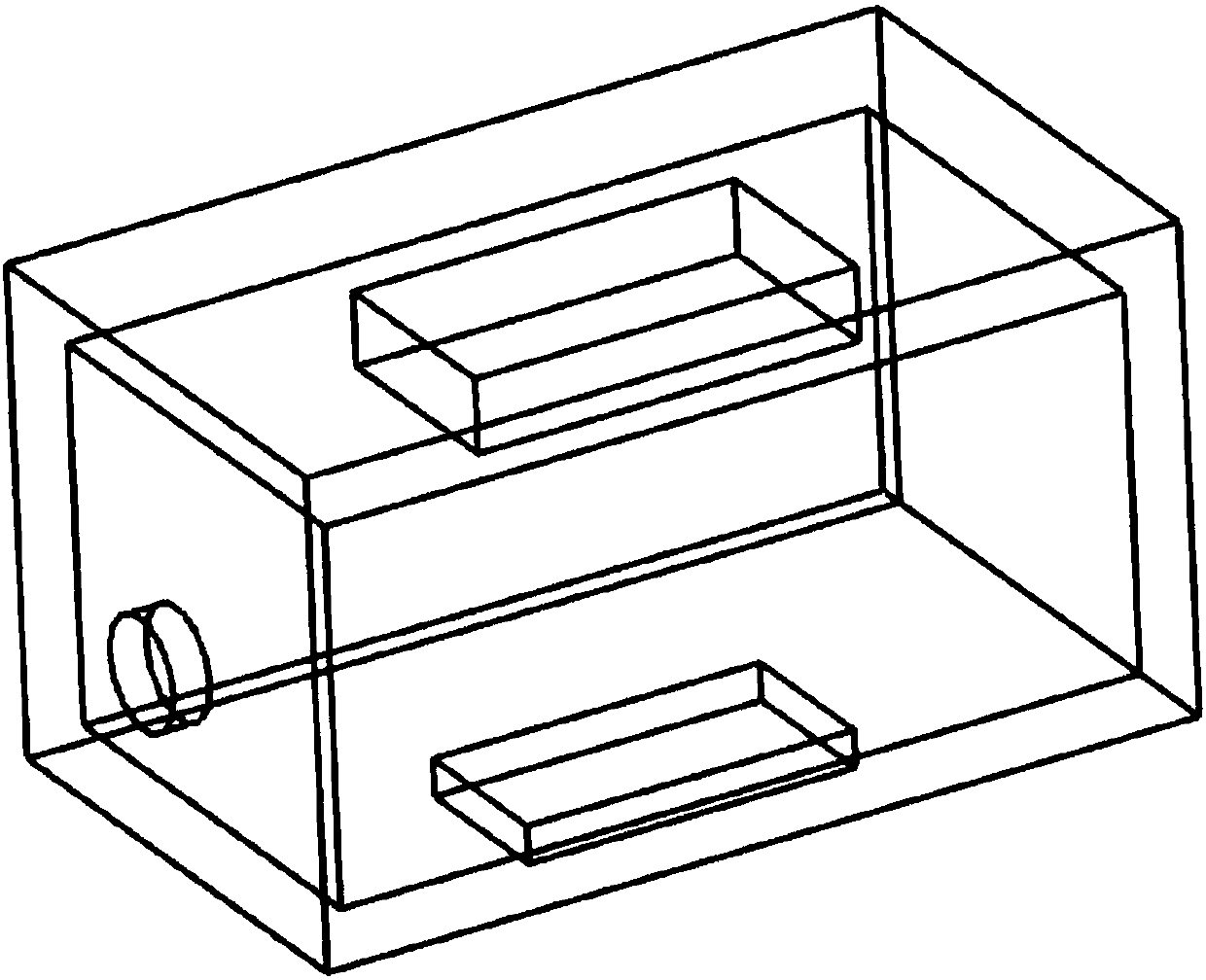

[0024] refer to Figure 1-3 . The low-temperature pore-making device of the fiber composite material / metal laminated structure of the present invention includes a self-pressurized liquid nitrogen tank 1, a booster valve 2, an empty valve 3, a heat-insulating pipe 4, an electric proportional regulating valve 5, a liquid storage tank 6, a heat-insulating Device 7, temperature sensor 8 and digital display temperature controller 9. The capacity of the self-pressurized liquid nitrogen tank 1 is 50L, when the empty valve 3 on the self-pressurized liquid nitrogen tank 1 is closed, the booster valve 2 is opened, and the continuous infusion starts when the internal pressure reaches 0.05Mpa; the heat-insulated pipe 4 The inner diameter is 10mm, the outer diameter is 15mm, it is wrapped by heat insulation material, and it is used for the transportation of low-temperature medium; the liquid storage tank 6 has a capacity of 5L, and is used to store the liquid nitrogen transported by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com