Fiber composite material/metal laminated structure low-temperature hole production device and method

A fiber composite material, metal lamination technology, used in boring/drilling, metal processing equipment, maintenance and safety accessories, etc. The effect of increased material brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

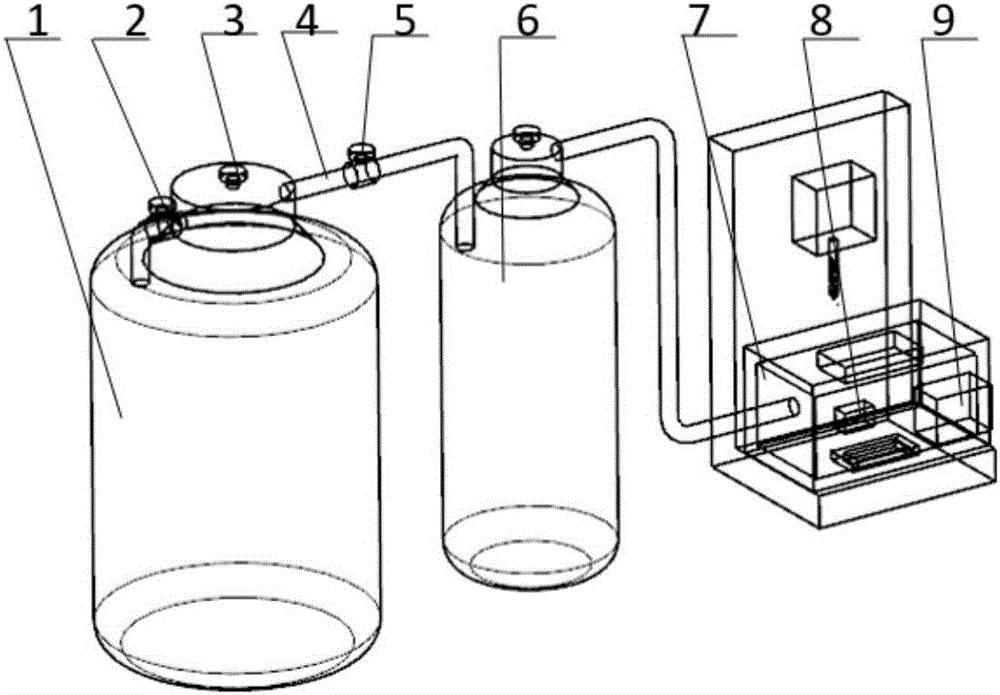

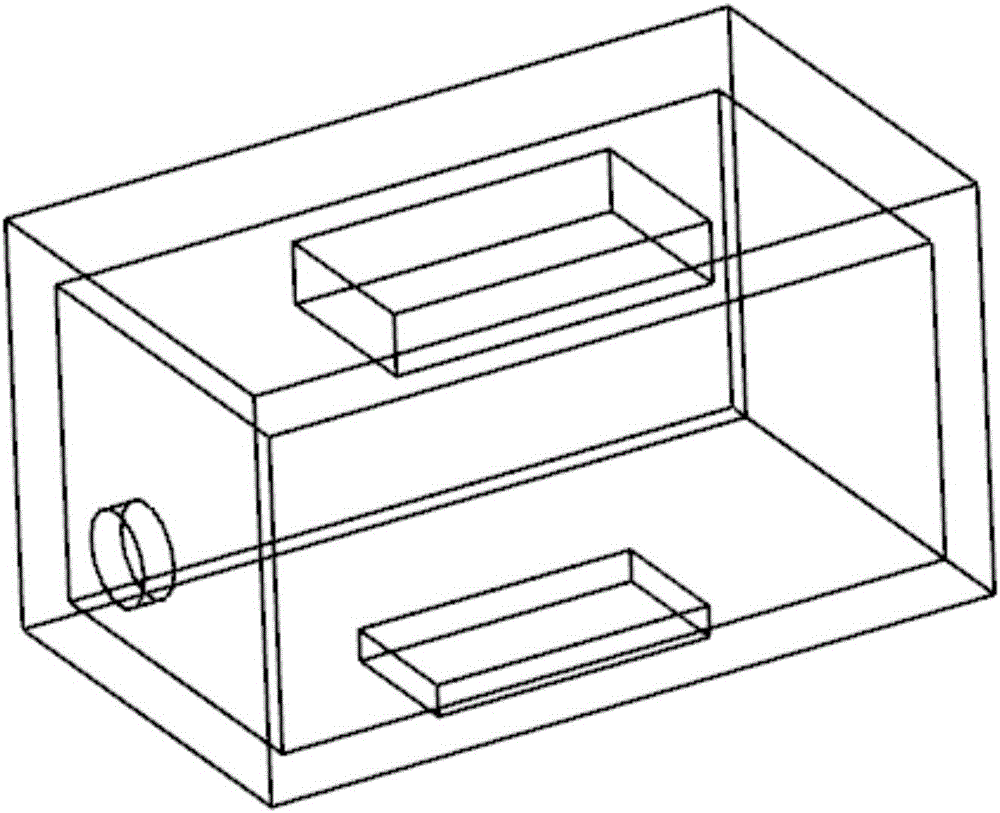

[0024] Reference Figure 1-3 . The fiber composite material / metal laminated structure low-temperature hole making device of the present invention includes a self-pressurized liquid nitrogen tank 1, a booster valve 2, an air valve 3, a heat insulation pipe 4, an electric proportional regulating valve 5, a liquid storage tank 6, and a heat insulation Device 7, temperature sensor 8 and digital display temperature controller 9. The self-pressurized liquid nitrogen tank 1 has a capacity of 50L. When the empty valve 3 on the self-pressurized liquid nitrogen tank 1 is closed, the booster valve 2 is opened, and the internal pressure reaches 0.05Mpa to start continuous infusion; heat insulation pipe 4 The inner diameter is 10mm and the outer diameter is 15mm. It is wrapped by insulation material and used for the transportation of low-temperature medium; the liquid storage tank 6 has a capacity of 5L and is used to store the liquid nitrogen transported by the self-pressurized liquid nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com