Preparation method of monoammonium glycyrrhizinate

A technology of glycyrrhizic acid monoammonium salt and glycyrrhizic acid is applied in the directions of steroids, organic chemistry, etc., can solve the problems of complex method, low yield, insufficient purity of finished products, etc., and achieves simplified preparation process, high purity and yield, The effect of reducing the generation of alkali-soluble impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of monoammonium glycyrrhizinate, comprising:

[0026] A) extracting licorice with an organic solvent, acid precipitation, and obtaining crude glycyrrhizic acid;

[0027] B) extracting the crude product glycyrrhizic acid with an organic solvent, decolorizing and ammoniating to obtain an ammoniated solution;

[0028] C) ultrafiltering the ammoniated solution to obtain monoammonium glycyrrhizinate.

[0029] In the invention, firstly, the licorice is extracted with an organic solvent and acid-precipitated to obtain crude glycyrrhizic acid. In the present invention, firstly, the licorice is extracted with an organic solvent. The licorice in the present invention is preferably extracted after being pulverized. The method of pulverization is not limited in the present invention, it can be pulverized into grass silk, and the pulverization method well known to those skilled in the art can be used. The organic solvent is pref...

Embodiment 1

[0066] Weigh 200g of crushed licorice, add 1.6L of 91% ethanol, ultrasonically extract at 60°C for 1h, and filter; The pH was 2.1, and 20.0 g of crude glycyrrhizic acid was obtained. Through measurement and calculation, the extraction rate of glycyrrhizic acid was 92.8%, and the content of glycyrrhizic acid in the crude glycyrrhizic acid was 31.2%.

[0067] The crude glycyrrhizic acid was extracted twice with 150 ml of 91% ethanol. After the ethanol extract was decolorized with activated carbon, ammonia water was added to adjust the pH value to 4.8, and ammoniated to obtain an ammoniated solution.

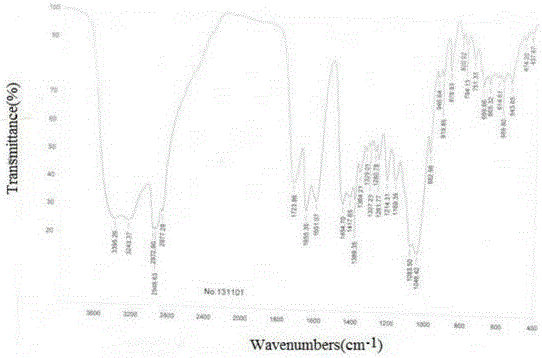

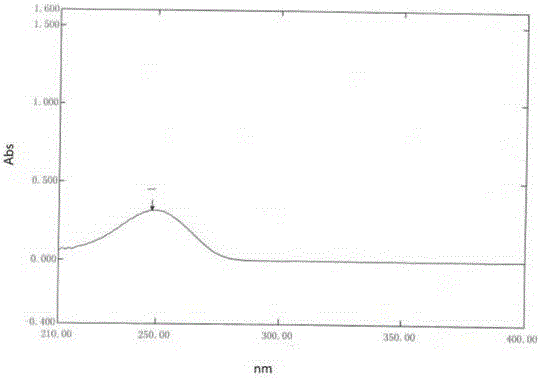

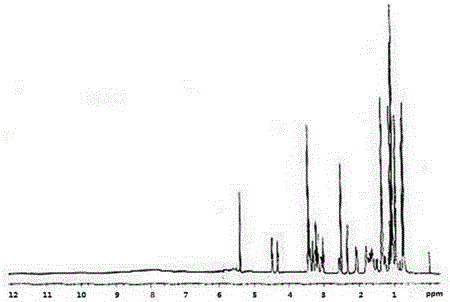

[0068] The ammoniated solution is ultrafiltered with a polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 2500-3000. The temperature is 30°C, the pressure is 0.05Mpa, and the feed concentration is 30g / L. The filtrate is crystallized, filtered, dried, and pulverized to obtain the product . Using ultraviolet absorption spectroscopy, infrared absorption spec...

Embodiment 2

[0070] Weigh 200 g of crushed licorice, add 2.0 L of acetone, ultrasonically extract at 50 ° C for 1 h, and filter; add 2.0 L of acetone to the filter residue, ultrasonically extract at 50 ° C for 1 h, filter, combine the filtrates, and use 5% hydrochloric acid to precipitate until the pH is 1.9, to obtain Crude glycyrrhizic acid is 19.8g, the extraction rate of glycyrrhizic acid is 90.5%, and the content of glycyrrhizic acid in crude glycyrrhizic acid is 30.5%.

[0071] The crude glycyrrhizic acid was extracted twice with 160 mL of 93% ethanol. After the ethanol extract was decolorized with activated carbon, ammonia water was added to adjust the pH value to 5.0, and ammoniated to obtain an ammoniated solution.

[0072] The ammoniated liquid is subjected to membrane ultrafiltration using a polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 2500-3000. The temperature is 30°C, the pressure is 0.10Mpa, and the feed concentration is 40g / L. The filtrate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com