Preparation method for concrete viscosity regulator

A viscosity regulator and concrete technology, which is applied in the field of concrete admixtures, can solve the problems of uneven internal voids, hardening of the floor, and easy flow of green ecological concrete paste, and achieve the suppression of segregation and bleeding, good compatibility, and inhibition The effect of segregated bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

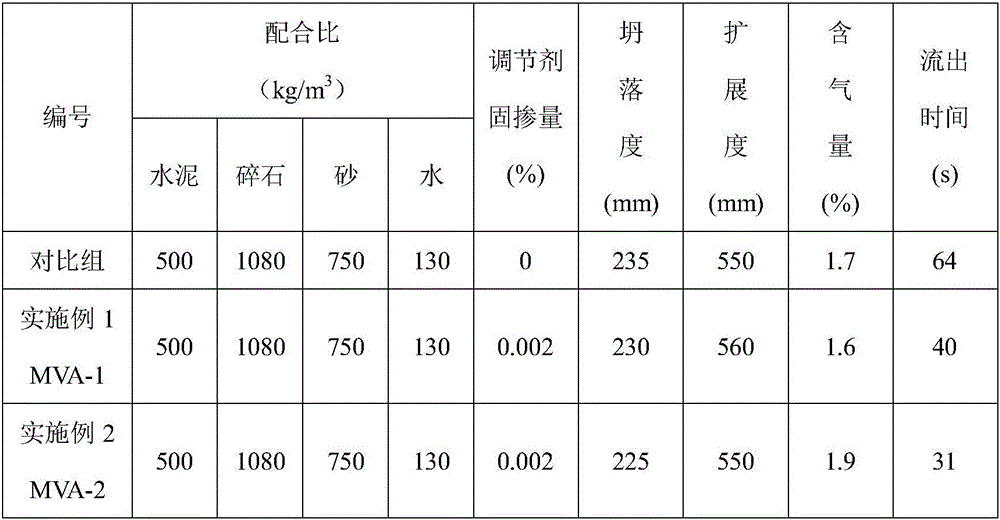

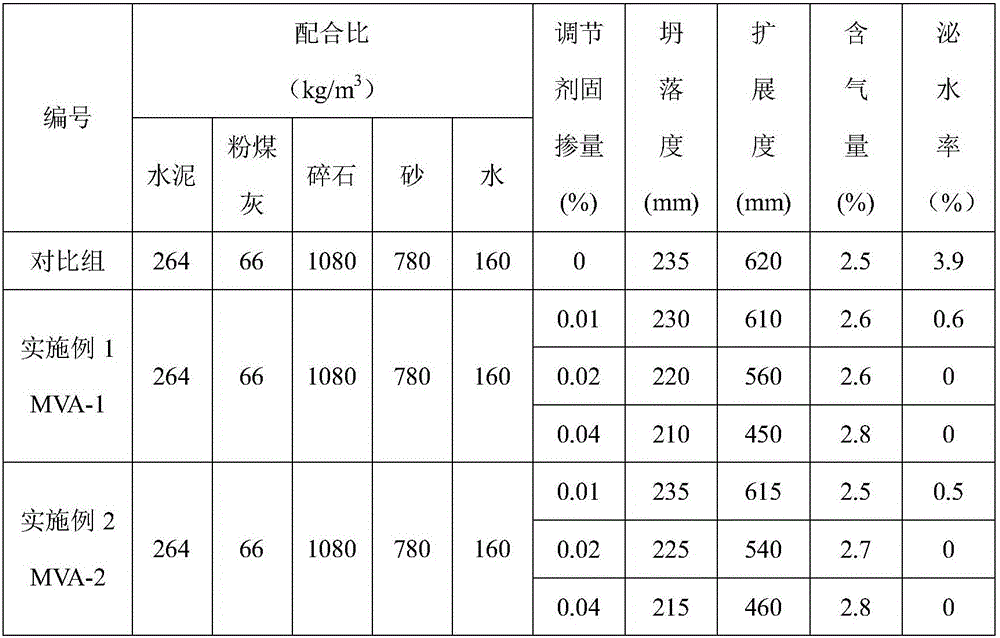

Examples

Embodiment 1

[0027] 1) Put 45 parts of acrylamide, 5 parts of acrylic acid and 100 parts of water into the bottom of the kettle, control the temperature at 30°C to 35°C, stir until the acrylamide is fully dissolved, then put in 3.0 parts of hydrogen peroxide, and stir for 10 minutes;

[0028] 2) Evenly add 70 parts of a mixed aqueous solution containing 0.05 parts of mercaptoethanol and 0.20 parts of L-ascorbic acid dropwise for 30 minutes, and slowly stir;

[0029] 3) Stand at constant temperature for 3 hours under the condition of 30℃~35℃;

[0030] 4) After diluting with water to a concentration of 10%, add 0.10 part of polyethylene glycol bis-itaconate, and raise the temperature to 60°C-65°C;

[0031] 5) Add 15 parts of an aqueous solution containing 1.0 part of persulfate dropwise for 1 hour, and slowly stir;

[0032] 6) Keep the temperature at 60℃~65℃ for 3h;

[0033] 7) Cool down to 40°C, add 30% liquid caustic soda to adjust the pH value to 5-6, and discharge to obtain the product...

Embodiment 2

[0035] 1) Put 40 parts of acrylamide, 10 parts of acrylic acid and 100 parts of water into the bottom of the kettle, control the temperature at 30°C to 35°C, stir until the acrylamide is fully dissolved, then put in 3.0 parts of hydrogen peroxide, and stir for 10 minutes;

[0036] 2) Evenly add 70 parts of a mixed aqueous solution containing 0.10 parts of 3-mercaptopropionic acid and 0.20 parts of L-ascorbic acid dropwise for 30 minutes, and slowly stir;

[0037] 3) Stand at constant temperature for 3 hours under the condition of 30℃~35℃;

[0038] 4) After diluting with water to a concentration of 10%, add 0.20 parts of polyethylene glycol bis-itaconate, and raise the temperature to 60°C-65°C;

[0039] 5) Add 20 parts of an aqueous solution containing 2.0 parts of ammonium persulfate dropwise for 1 hour, and slowly stir;

[0040] 6) Keep the temperature at 60℃~65℃ for 3h;

[0041] 7) Cool down to 40°C, add 30% liquid caustic soda to adjust the pH value to 5-6, and discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com