Antistatic low-VOC (volatile organic compound) polyamide 6 composite material and method for preparing same

A composite material and polyamide technology, applied in the field of antistatic low-VOC polyamide 6 composite material and its preparation, can solve the problem of high VOC and achieve the effect of reducing VOC value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

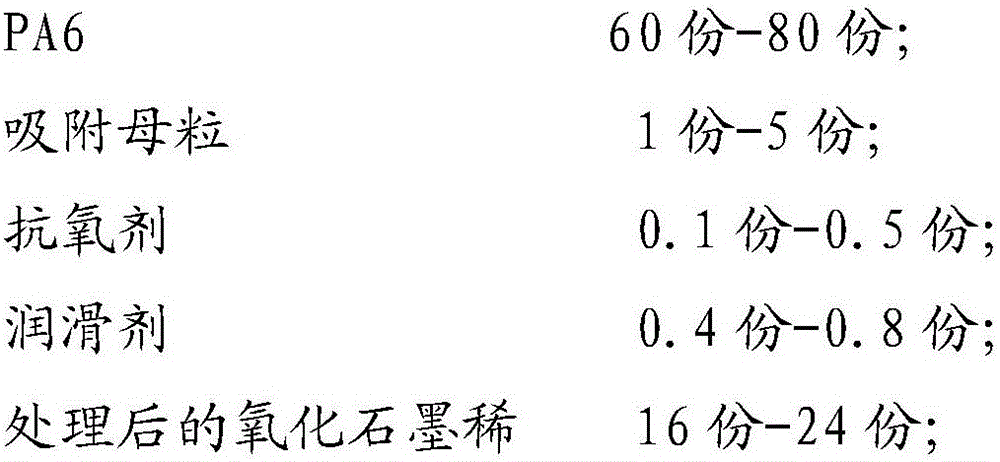

Method used

Image

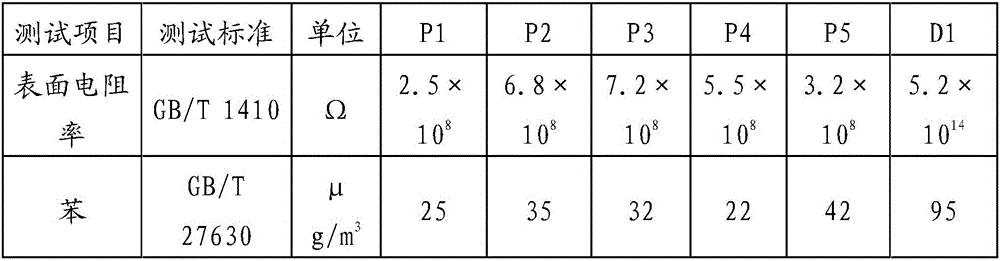

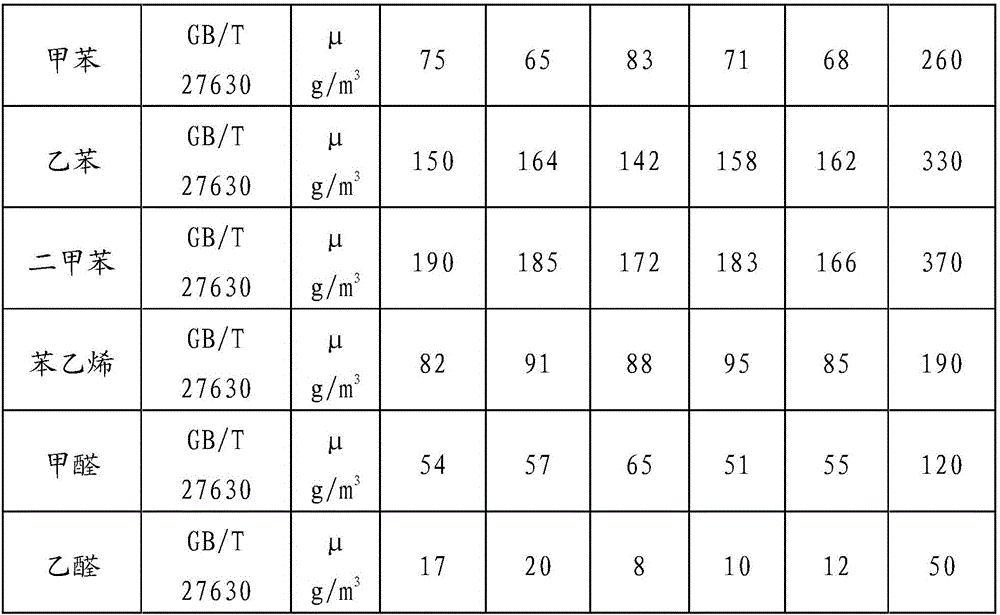

Examples

preparation example 1

[0040] The preparation method of described adsorption masterbatch, comprises the following steps:

[0041] 1) Fully mix polypropylene and mica according to the proportioning ratio, and extrude polypropylene pre-expanded particles in the extruder; the mass ratio of polypropylene and mica is 40:6;

[0042] 2) with n-heptane as blowing agent, the polypropylene pre-expanded particles prepared in step 1) are foamed to obtain expanded polypropylene; the mass ratio of said n-heptane to polypropylene pre-expanded particles is 50:60;

[0043] 3) Mix foamed polypropylene and water in a high-speed mixer for 5-10 minutes to prepare adsorption masterbatch.

preparation example 2

[0045] The preparation method of described adsorption masterbatch, comprises the following steps:

[0046] 1) Fully mix polypropylene and mica according to the proportioning ratio, and extrude polypropylene pre-expanded particles in the extruder; the mass ratio of polypropylene and mica is 40:10;

[0047] 2) take n-heptane as blowing agent, the polypropylene pre-expanded particle that step 1) is obtained is foamed, makes expanded polypropylene; The mass ratio of described n-heptane and polypropylene pre-expanded particle is 50:80;

[0048] 3) Mix foamed polypropylene and water in a high-speed mixer for 5-10 minutes to prepare adsorption masterbatch.

preparation example 3

[0050] The preparation method of described adsorption masterbatch, comprises the following steps:

[0051] 1) Fully mix polypropylene and mica according to the proportion, and extrude polypropylene pre-expanded particles in the extruder; the mass ratio of polypropylene and mica is 40:8;

[0052] 2) with n-heptane as blowing agent, the polypropylene pre-expanded particles prepared in step 1) are foamed to obtain expanded polypropylene; the mass ratio of said n-heptane to polypropylene pre-expanded particles is 50:70;

[0053] 3) Mix foamed polypropylene and water in a high-speed mixer for 5-10 minutes to prepare adsorption masterbatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com