Preparation method of coating of grapheme modified polyphenylene sulfide

A technology of graphene modification and polyphenylene sulfide, applied in the direction of anti-corrosion coatings, coatings, etc., can solve problems such as complex methods, harsh conditions, and difficult operation, and achieve good compatibility, improve accuracy, and increase wear resistance The effect of damage ability and corrosion resistance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method for a coating of graphene-modified polyphenylene sulfide, the coating comprises the following components in parts by weight: 46 parts of acrylic resin emulsion, 39 parts of modified polyphenylene sulfide, and 10 parts of polytetrafluoroethylene , 6 parts of industrial flavor (apple flavor), 7 parts of filler (chrome yellow), 9 parts of filler (iron blue), 1 part of dispersant (titanate coupling agent); the filler is mixed xylene, mass number 15 parts; 6 parts of graphene;

[0035] The coating is obtained through the following steps:

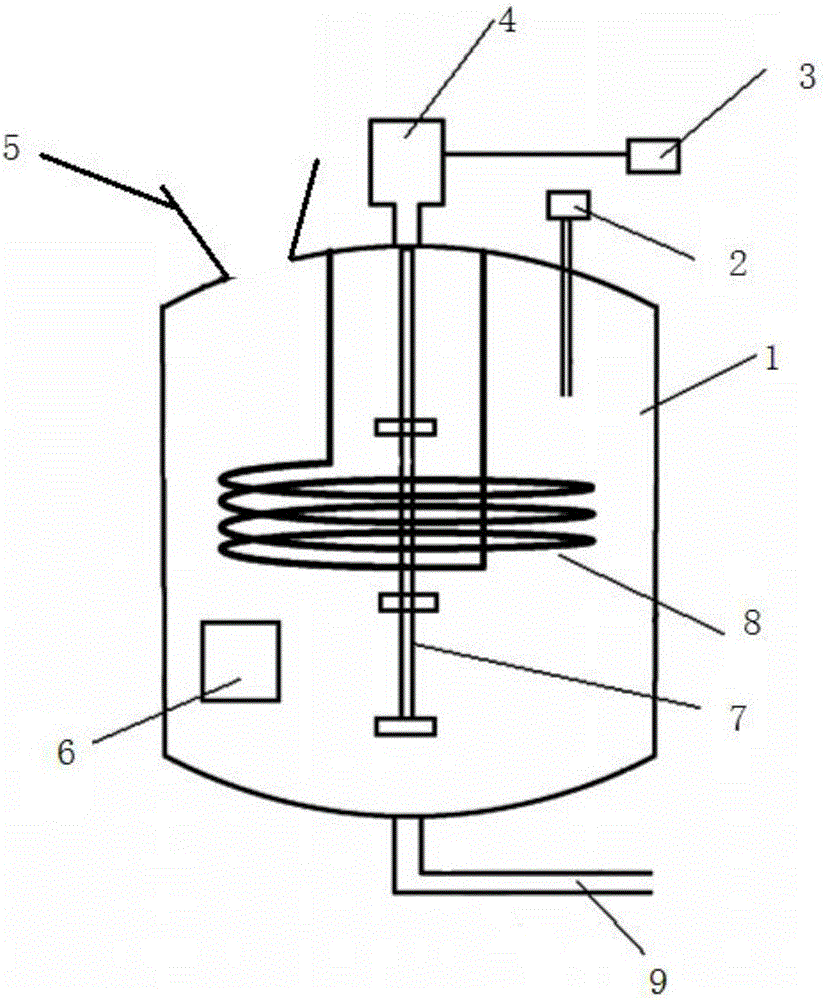

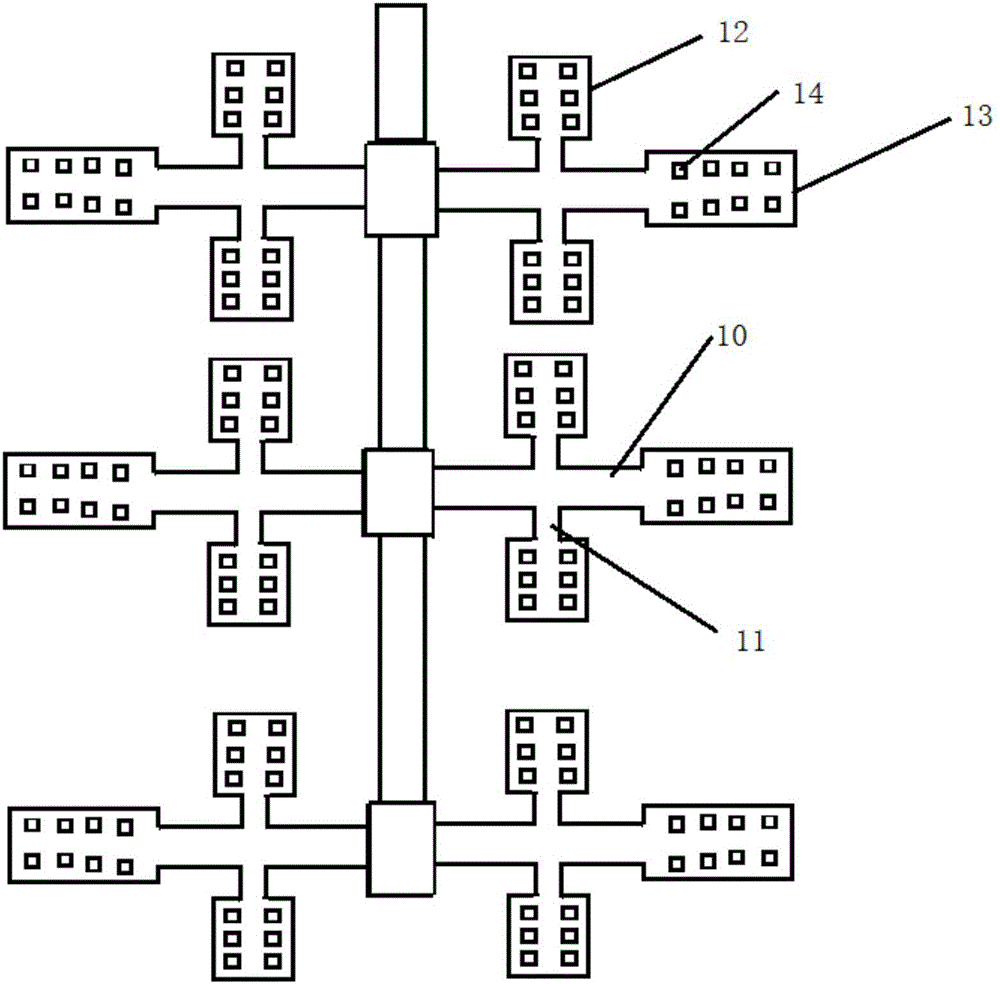

[0036] Step (1) Preparation of modified polyphenylene sulfide:

[0037] A) Take polyphenylene sulfide and graphene and place them in a grinding device to grind them into fine powder;

[0038] B) Pour the mixed fine powder in step A) into a beaker, add ethanol to prepare a suspension with a suspension concentration of 1:25, and disperse it by ultrasonic for 10 minutes;

[0039] C) Pour the concentration of the suspen...

Embodiment 2

[0048] A preparation method of a graphene-modified polyphenylene sulfide coating, the coating comprises the following components in parts by weight: 85 parts of acrylic resin emulsion, 15 parts of modified polyphenylene sulfide, 40 parts of polytetrafluoroethylene , 18 parts of industrial essence (almond essence), 2 parts of filler (toluidine blue), 4 parts of dispersant (titanate coupling agent), 6 parts of dispersant (vinyl bisstearamide); the filler is Mixed xylene, the mass number is 3 parts; Graphene 29 parts;

[0049] The coating is obtained through the following steps:

[0050] Step (1) Preparation of modified polyphenylene sulfide:

[0051] A) Take polyphenylene sulfide and graphene and place them in a grinding device to grind them into fine powder;

[0052] B) Pour the mixed fine powder in step A) into a beaker, add ethanol to prepare a suspension with a suspension concentration of 1:30, and disperse it by ultrasonic for 15 minutes;

[0053] C) Pour the concentrati...

Embodiment 3

[0062] A preparation method for a coating of graphene-modified polyphenylene sulfide, the coating comprises the following components in parts by weight: 55 parts of acrylic resin emulsion, 32 parts of modified polyphenylene sulfide, and 15 parts of polytetrafluoroethylene , 8 parts of industrial flavor (peach flavor), 7 parts of filler (iron red), 7 parts of filler (loess), 2 parts of dispersant (polyvinylpyrrolidone); the filler is mixed xylene, the mass number is 12 parts; 12 parts of graphene;

[0063] The coating is obtained through the following steps:

[0064] Step (1) Preparation of modified polyphenylene sulfide:

[0065] A) Take polyphenylene sulfide and graphene and place them in a grinding device to grind them into fine powder;

[0066] B) Pour the mixed fine powder in step A) into a beaker, add ethanol to prepare a suspension with a suspension concentration of 1:45, and disperse it by ultrasonic for 15 minutes;

[0067] C) Pour the concentration of the suspensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com