A kind of preparation method of squid ink-alginate composite fiber

An alginate and composite fiber technology is applied in the directions of alginate artificial filament, spinning solution preparation, fiber chemical characteristics, etc., to achieve the effects of simple source of raw materials, more retention, and high dry breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

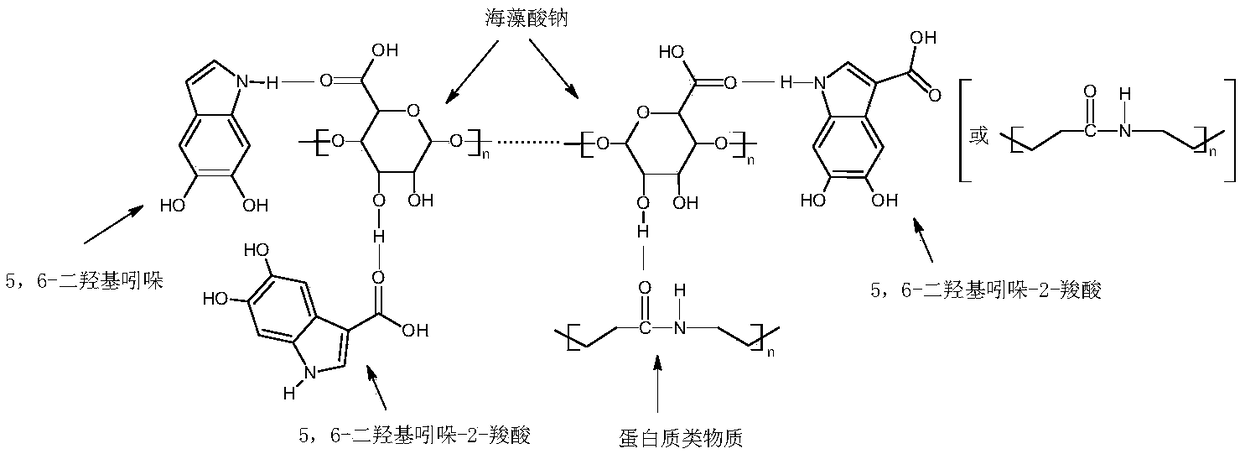

Image

Examples

Embodiment 1

[0050] The preparation method is as follows:

[0051] The first step, the preparation of squid ink extract

[0052] In parts by mass, weigh 60 parts of sodium alginate powder, 5 parts of ink sac (containing ink), and 1 part of emulsifier gum arabic;

[0053] Add the ink sac to the homogenizer, add ice water in equal parts by mass, and homogenize for 10 minutes; filter the obtained mixture through two layers of gauze to obtain the crude squid ink extract.

[0054] After freezing the crude squid ink extract obtained into a solid state, place it in a freeze dryer, freeze-dry it at a cold trap temperature of -40°C for 10 hours, and then use a grinding pump to circulate and grind for 15 minutes to obtain a refined squid ink extract;

[0055] The second step, the preparation of squid ink-sodium alginate spinning solution

[0056] The sodium alginate powder obtained was prepared into a sodium alginate solution with a mass percentage concentration of 8%, an emulsifier was added unde...

Embodiment 2

[0064] The preparation method is as follows:

[0065] The first step, the preparation of squid ink extract

[0066] In parts by mass, weigh 70 parts of sodium alginate powder, 5 parts of ink sac (containing ink), and 1 part of emulsifier (among them, 0.5 parts of gum arabic and 0.5 parts of xanthan gum);

[0067] Add the ink sac to the homogenizer, add ice water in equal parts by mass, and homogenize for 10 minutes; filter the obtained mixture through two layers of gauze to obtain the crude squid ink extract.

[0068] After freezing the crude squid ink extract obtained into a solid state, place it in a freeze dryer, freeze-dry it at a cold trap temperature of -40°C for 10 hours, and then use a grinding pump to circulate and grind for 15 minutes to obtain a refined squid ink extract; Two steps, preparation of squid ink-sodium alginate spinning solution

[0069] The obtained sodium alginate powder was prepared into a sodium alginate solution with a mass percent concentration o...

Embodiment 3

[0077] The preparation method is as follows:

[0078] The first step, the preparation of squid ink extract

[0079] In parts by mass, weigh 80 parts of sodium alginate powder, 5 parts of ink sacs (containing ink), and 1 part of emulsifier (among them, 0.5 parts of gum arabic, 0.3 parts of xanthan gum, and 0.2 parts of tragacanth gum);

[0080] Add the ink sac to the homogenizer, add ice water in equal parts by mass, and homogenize for 10 minutes; filter the obtained mixture through two layers of gauze to obtain the crude squid ink extract.

[0081] After freezing the crude squid ink extract obtained into a solid state, place it in a freeze dryer, freeze-dry it at a cold trap temperature of -40°C for 10 hours, and then use a grinding pump to circulate and grind for 15 minutes to obtain a refined squid ink extract; Two steps, preparation of squid ink-sodium alginate spinning solution

[0082] The obtained sodium alginate powder was prepared into a sodium alginate solution with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com