wet concrete sprayer

A wet blasting machine and concrete technology, applied in earth-moving drilling, shaft equipment, wellbore lining, etc., can solve the problems of corrosion and damage of electrical components, safety accidents, humidity on the work site, etc., and achieve the effect of avoiding corrosion and damage and preventing safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

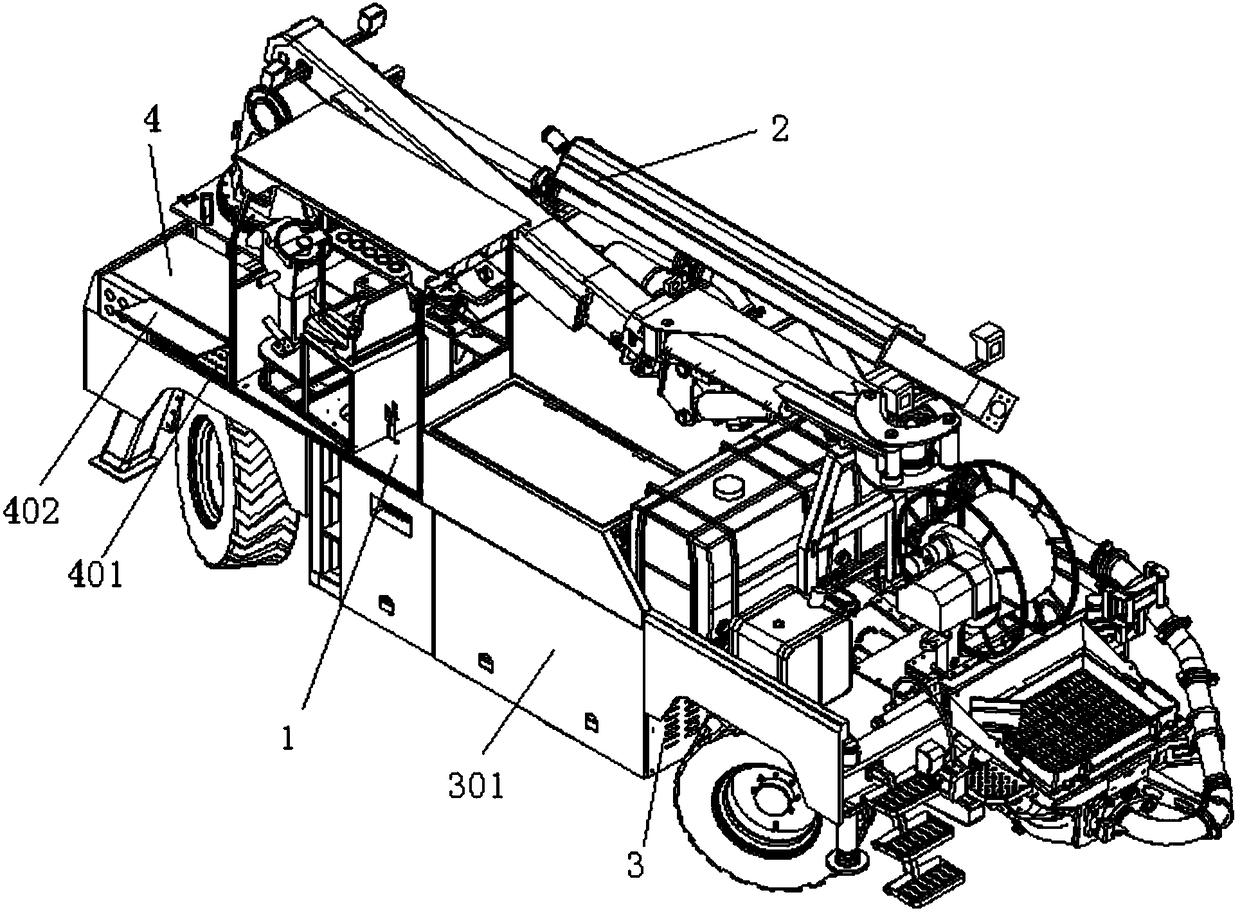

[0023] see figure 1 , figure 1 A concrete embodiment of the wet concrete spraying machine of the present invention is provided, wherein, figure 1 It is a schematic diagram of the overall structure of a concrete wet spraying machine in Embodiment 1 of the present invention.

[0024] The invention provides a concrete wet spraying machine, which includes a car body 1, which is used to provide power for the operation of the concrete wet spraying machine, and at the same time provide a bearing unit for the installation of other mechanisms.

[0025] An arm frame 2 is arranged above the car body 1, and the arm frame 2 is generally used for installing a spraying system, so as to facilitate the control of the spraying area of the concrete wet spraying machine.

[0026] The car body 1 is provided with a main electric control cabinet 3, which is used to provide space for the installation of electrical components. The side wall of the main electric control cabinet 3 is provided with a...

Embodiment 2

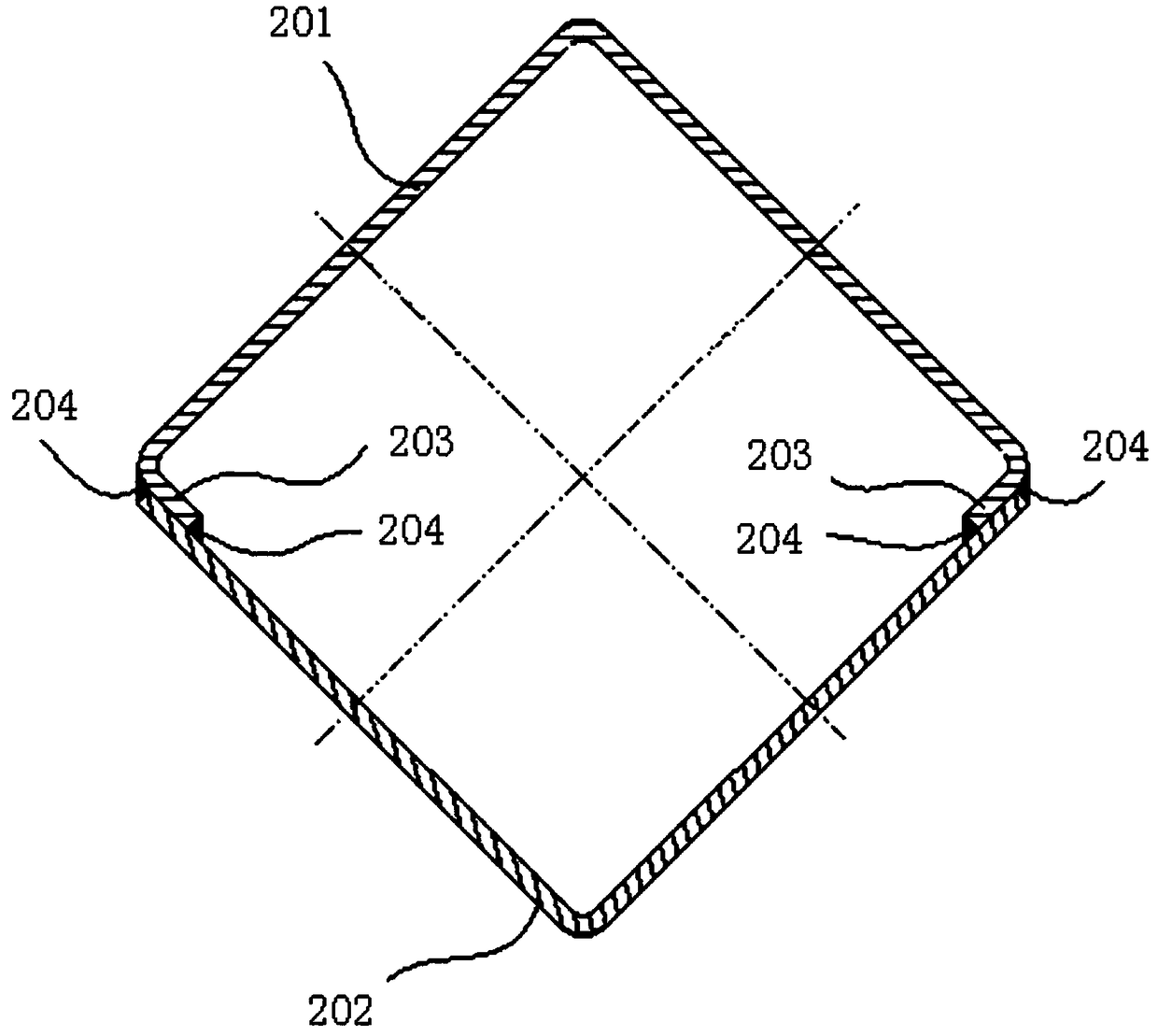

[0033] see figure 2 , figure 2 A specific embodiment of a jib of the present invention is provided, wherein, figure 2 It is a structural schematic diagram of the cross-section of the boom according to Embodiment 2 of the present invention.

[0034] In actual operation, in order to increase the spraying range of the concrete spraying truck, the boom of the existing concrete spraying truck generally uses a telescopic boom. Considering that the overall weight of the boom should not be too large and the telescopic length of the boom needs to be extended, it is generally required The cross-sectional size of the telescopic arm frame is small and has suitable rigidity to meet the requirements of use. Existing booms are generally manufactured in two ways, one is integrally formed by a rectangular tube of a specific specification; the other is tailor-welded by two bent plates, and the welding seam is at a symmetrical position in the center of the boom body. The first method needs...

Embodiment 3

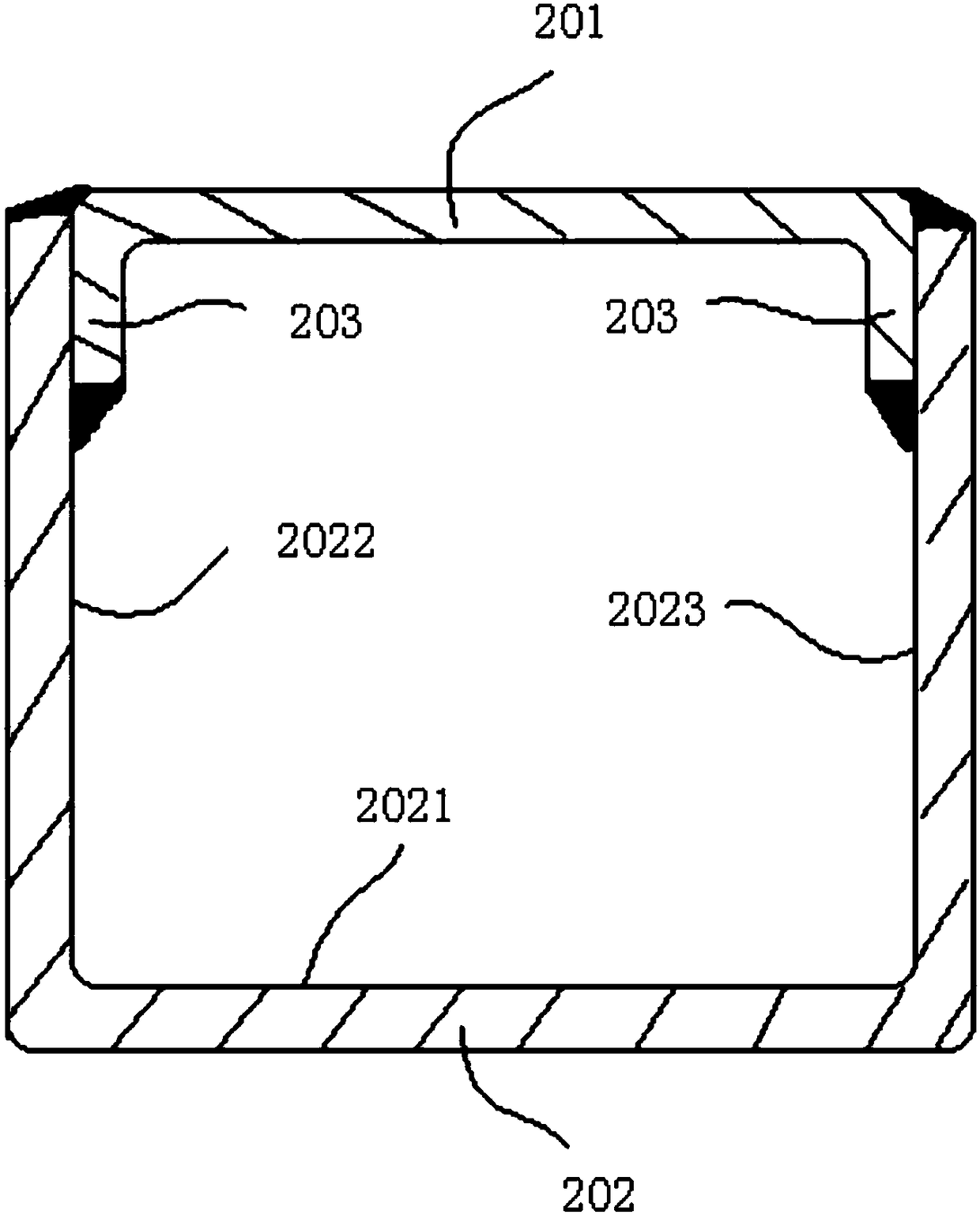

[0048] see image 3 , image 3 A second specific embodiment of a jib of the present invention is provided, wherein, image 3 It is a structural schematic diagram of the cross-section of the boom according to Embodiment 3 of the present invention.

[0049] In this embodiment, the first half frame plate 201 is a flat plate, and the second half frame plate 202 includes a bottom plate 2021, a left side plate 2022 connected to the left side of the bottom plate 2021, and a left side plate 2022 connected to the right side of the bottom plate 2021. The right side panel 2023. Specifically, the overlapping strips 203 can be vertically connected to both sides of the flat first frame half 201 , and the overlapping strips 203 can also be vertically connected to the left side panel 2022 and the right side panel 2023 of the second half frame panel 202 . In this embodiment, the lapping strips 203 are vertically connected to both sides of the first half frame plate 201 which is a flat plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com