Ceramic glass base material heat radiation unit system with thick film circuit chip for heat supply

A thick-film circuit and glass-ceramic technology, which is applied in the field of heat-dissipating unit systems for thick-film circuit chips and glass-ceramic substrates, can solve problems such as waste of power resources, short supply, and shortage of urban power supply, and achieve simple structure, strong practicability, The effect of heat dissipation power density dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

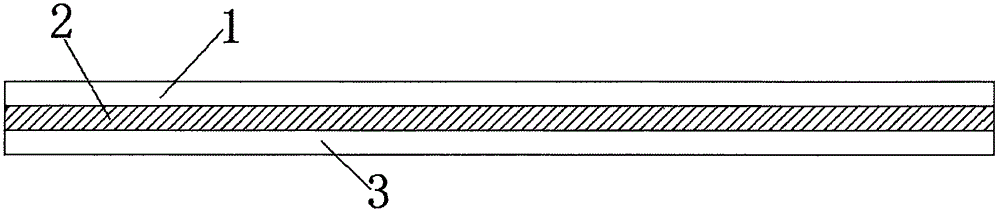

[0018] Such as figure 1 and combine figure 2 As shown, a thick-film circuit chip glass-ceramic substrate cooling unit system for heating, including a first glass layer 1, a second glass layer 3 and a thick-film circuit chip 2, the rear film circuit chip 2 clamps Between the first glass layer 1 and the second glass layer 3, both of the first glass layer 1 and the second glass layer 3 are tempered glass, and the rear film circuit chip 2 includes a rear film circuit and a control chip, the The rear film circuit is connected to the control chip, the film thickness of the rear film circuit is greater than 10um, and the rear film circuit chips 2 are sintered on the first glass layer 1 and the second glass layer 3 respectively.

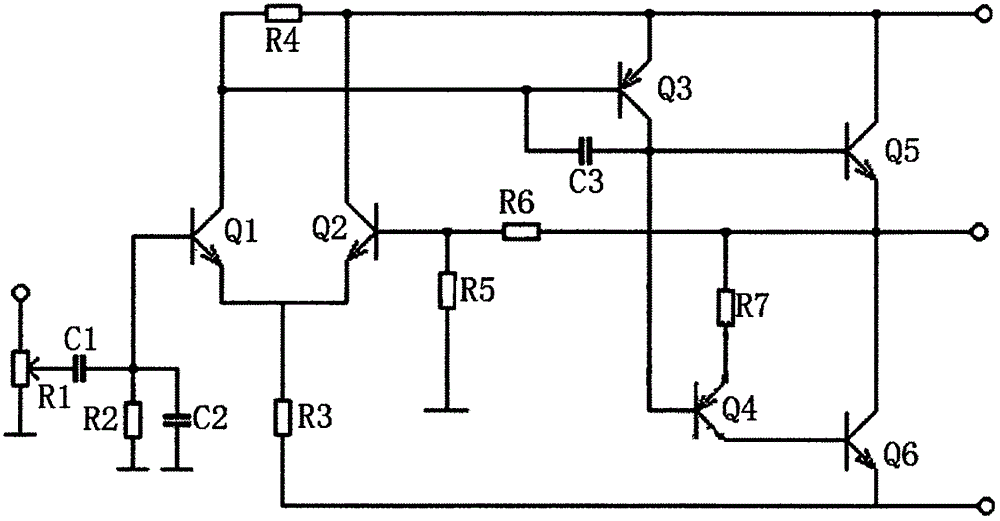

[0019] Further, the rear membrane circuit includes a first triode Q1, a second triode Q2, a third triode Q3, a fourth triode Q4, a fifth triode Q5, a sixth triode Q6, The first capacitor C1, the second capacitor C2, the third capacitor C3, the first resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com