Two-stage type flue gas cleaning system for garbage incinerator

A flue gas purification system and waste incinerator technology, applied in gas treatment, chemical instruments and methods, dispersed particle filtration, etc., can solve problems such as heat loss and increased energy consumption, and achieve the effect of reducing energy loss and improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

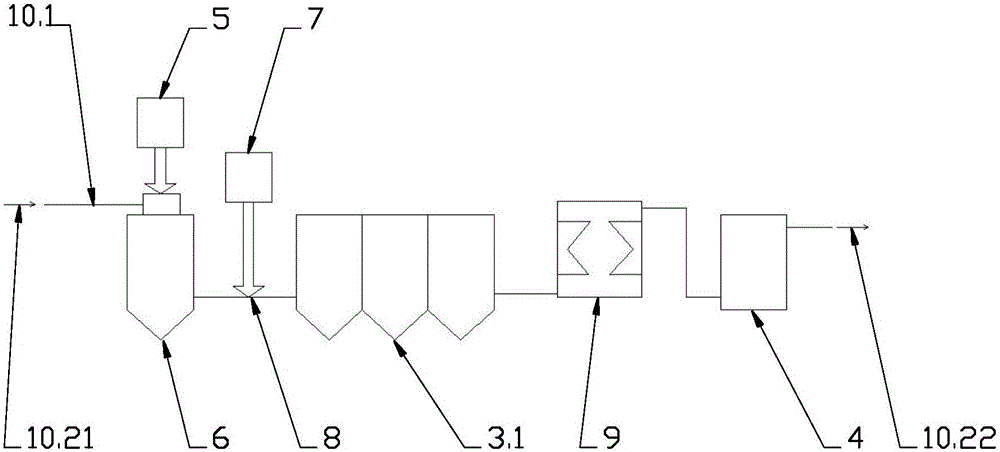

[0022] figure 1 It is a device layout diagram of an embodiment of the prior art. The figure shows that in the prior art, the flue gas purification system installed in the flue gas pipeline of the waste incinerator is sequentially composed of a lime slurry preparation system 5 and a semi-dry reaction tower (rotary atomizer) according to the direction of flue gas flow. 6. Activated carbon storage and delivery system 7. Activated carbon injection system 8. First-stage bag filter 3.1. Heat exchanger 9. Selective catalytic reduction device (SCR) 4. As shown in the figure, the waste incinerator flue gas purification system needs to install a heat exchanger 9 at the front end of the selective catalytic reduction (SCR) 4. The reason is that since the working temperature of the SCR is about 200°C, After flowing in from the flue gas pipe 10.1 according to the flue gas inflow direction 10.21, it enters the semi-dry reaction tower 6 and passes through the lime slurry rotary sprayer. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com