Bi-metal water-cooling casting mold for preparing aluminum alloy capable of achieving hydrolytic degradation

A technology for casting molds and aluminum alloys, which is applied in the field of preparing bimetallic water-cooled casting molds for water-degradable aluminum alloys, to achieve the effects of optimizing the microstructure, shortening the casting cycle, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

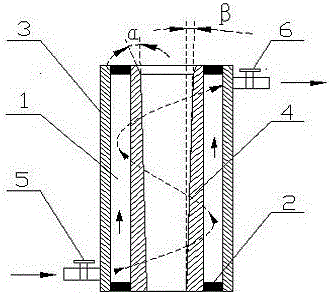

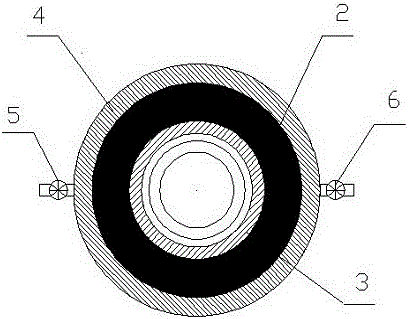

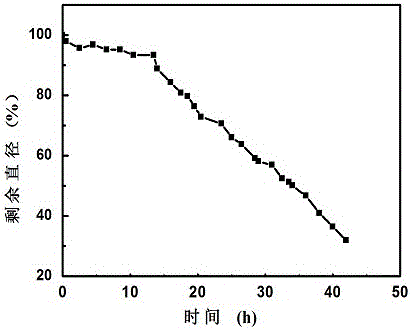

[0013] Example 1: Preparation of a bimetallic water-cooled casting mold for water-degradable aluminum alloys, the structure of which includes: an inner casting mold cavity 4, an outer metal of the casting mold 3, an annular water-cooling cavity 1, a metal ring 2 at the connecting part, and an inlet water flow regulating valve 5 and the water outlet flow regulating valve 6. When working, place the mold on the metal iron block (thickness greater than 10mm) gasket and fix it, connect the pipes to the water inlet and outlet, and connect with tap water, and then pour the molten metal liquid into the inner casting model In cavity 4, adjust the gears of valves 5 and 6 according to the optimum cooling rate required for casting crystallization at the same time as pouring, and control the water flow rate and water flow rate, so as to adjust the cooling rate to achieve the optimum crystallization temperature requirement and obtain the microstructure Small and well-behaved castings. Afte...

Embodiment 2

[0014] Embodiment 2: According to the description of the shape, material and details of the present invention in the specification, a bimetallic water-cooled casting mold meeting the requirements and having a certain size was manufactured. The specific dimensions are: mold height H=330mm, mold outer diameter D=140mm, inner diameter of the upper end of the truncated cone d1=100mm, inner diameter of the lower end of the truncated cone d1=90mm, inclination angle of the truncated cone β=1°.

Embodiment 3

[0015] Embodiment 3: According to the description of the shape, material and details of the present invention in the specification, a bimetallic water-cooled casting mold meeting the requirements and having a certain size was manufactured. The specific dimensions are: mold height H=330mm, mold outer diameter D=140mm, inner diameter of the upper end of the truncated cone d1=59.34mm, inner diameter of the lower end of the truncated cone d1=49.18mm, and the inclination angle of the truncated cone β=2°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com