Coking wastewater oil displacing demulsifier as well as preparation technology and application thereof

A demulsifier and oil displacement technology, which is applied in the control of water treatment parameters, water treatment of special compounds, water pollutants, etc., can solve the problems of poor treatment effect of coking wastewater, and achieve the effects of environmental friendliness, simple formula and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

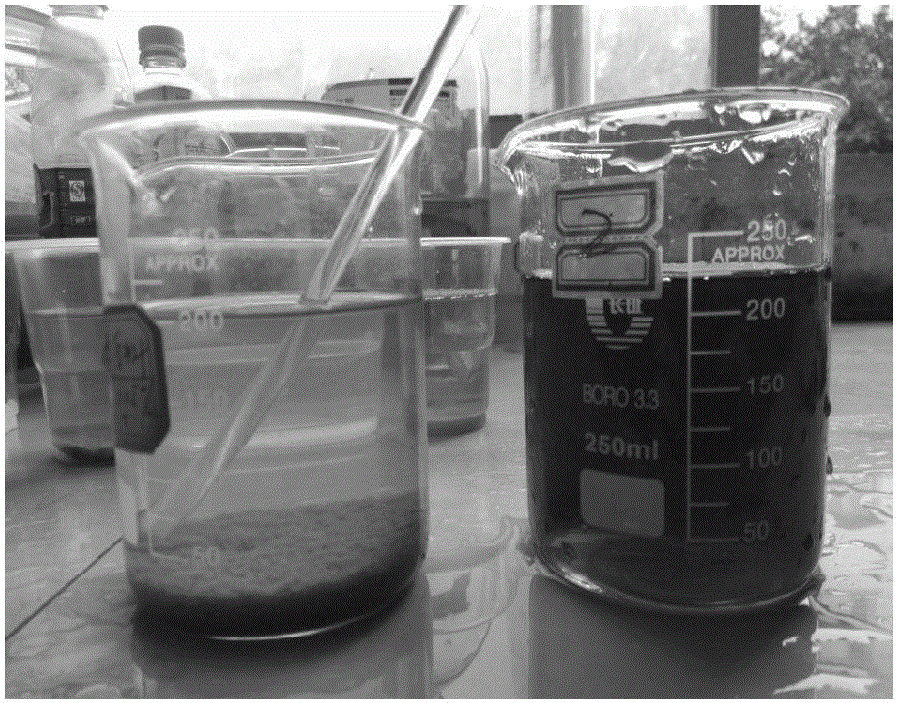

Image

Examples

Embodiment 1

[0032] Embodiment 1 The oil displacement demulsifier that this embodiment enumerates has the following composition (volume percentage):

[0033]

[0034]

[0035] The mass percentage concentration of above-mentioned dodecyl dimethyl benzyl ammonium chloride is 44%, the mass percentage concentration of tetradecyl dimethyl benzyl ammonium chloride is 50%, and the ionicity of cationic polyacrylamide is 40 %.

[0036] Preparation process: First, add cationic polyacrylamide to the reaction kettle in proportion; add 50% of the water consumption under continuous stirring, and continue stirring for 10 minutes, then add dodecyl dimethyl benzyl chloride in proportion Add ammonium chloride, tetradecyldimethylbenzyl ammonium chloride and vinyl polysiloxane emulsion, stir while adding, and slowly raise the temperature to 35 ° C, after stirring for 50 minutes, finally add the remaining water in proportion, stir Stop heating after 20 minutes, stir while cooling, and cool to room tempe...

Embodiment 2

[0037] Embodiment 2 The oil displacement demulsifier that this embodiment enumerates has the following composition (volume percentage):

[0038]

[0039]The mass percentage concentration of above-mentioned dodecyl dimethyl benzyl ammonium chloride is 44%, the mass percentage concentration of tetradecyl dimethyl benzyl ammonium chloride is 50%, and the ionicity of cationic polyacrylamide is 50 %.

[0040] Preparation process: First, add cationic polyacrylamide to the reaction kettle in proportion; add 60% of the water consumption under continuous stirring, and continue stirring for 20 minutes, then add dodecyl dimethyl benzyl chloride in proportion Add ammonium chloride, tetradecyldimethylbenzyl ammonium chloride and vinyl polysiloxane emulsion, stir while adding, and slowly raise the temperature to 40 ° C, stir for 55 minutes, finally add the remaining water in proportion, stir Stop heating after 25 minutes, stir while cooling, and cool to room temperature to obtain the oi...

Embodiment 3

[0041] Embodiment 3 The oil displacement demulsifier that this embodiment enumerates has the following composition (volume percentage):

[0042]

[0043] Wherein the mass percentage concentration of dodecyl dimethyl benzyl ammonium chloride is 44%, the mass percentage concentration of tetradecyl dimethyl benzyl ammonium chloride is 50%, and the ionicity of cationic polyacrylamide is 45% %.

[0044] Preparation process: First, add cationic polyacrylamide to the reaction kettle in proportion; add 55% of the water consumption under continuous stirring, and continue stirring for 15 minutes, then add dodecyl dimethyl benzyl chloride in proportion Ammonium chloride, tetradecyl dimethyl benzyl ammonium chloride and methoxypolysiloxane emulsion, stirring while adding, and slowly raising the temperature to 38 ° C, stirring for 55 minutes, and finally adding the remaining water in proportion, After stirring for 25 minutes, stop heating, stir while cooling, and cool to room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com