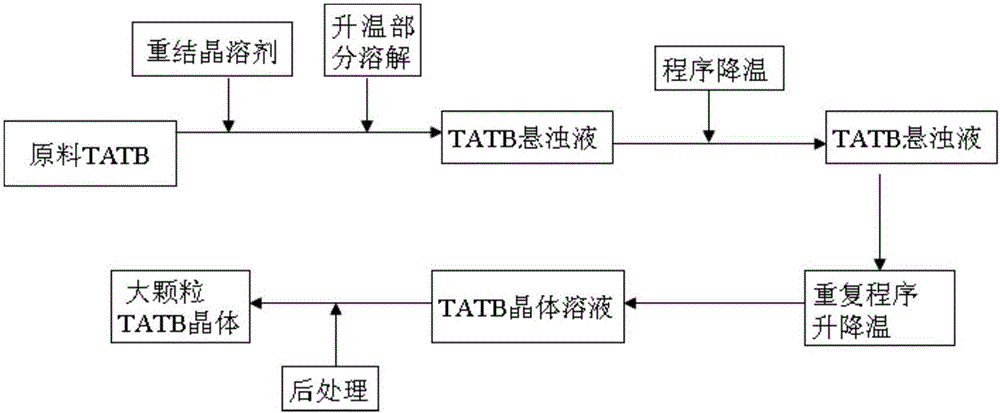

Method for preparing large-granule triaminotrinitrobenzene through circular heating and cooling

A technology of triaminotrinitrobenzene and large particles, which is applied in organic chemical methods, purification/separation of amino compounds, organic chemistry, etc., can solve problems such as large safety risks, limited production scale, and failure to meet application requirements, and achieve safety Good performance, increased mechanical strength, and improved charge fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

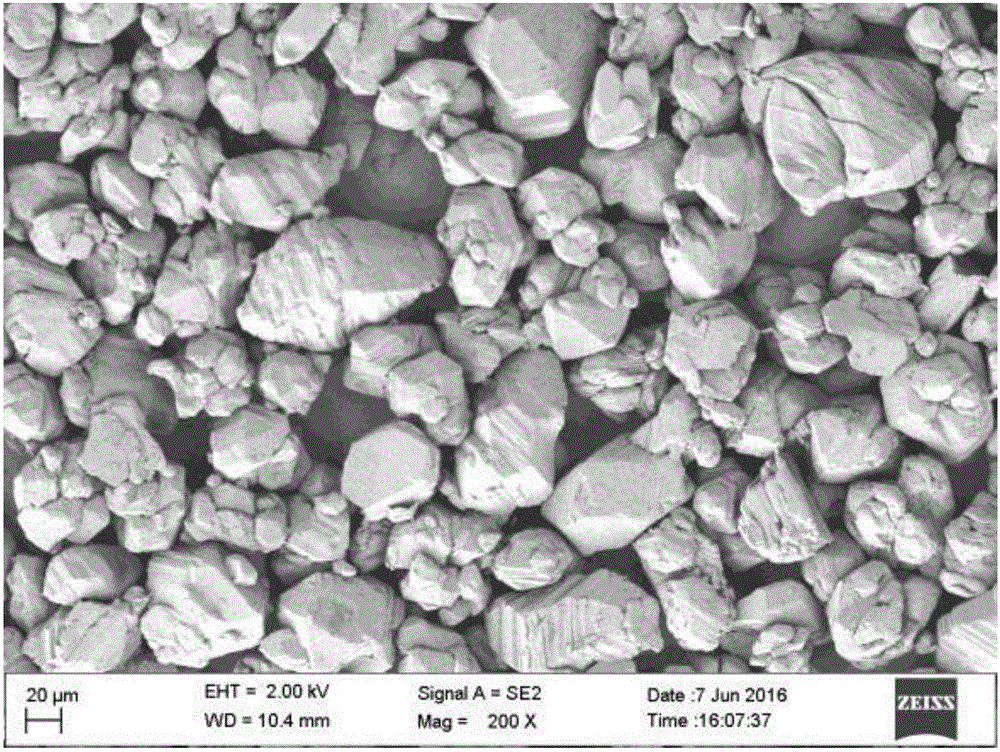

[0025] At room temperature, the raw material TATB (5g) with an average particle size of 10μm was added to dimethyl sulfoxide (100ml), the stirring speed was 100-300rpm, the temperature was raised to 120°C at a speed of 3°C / min and kept for 30 minutes, the TATB part Dissolve to obtain a TATB suspension, then lower the temperature to 20°C at a rate of 3°C / min according to the temperature control program, and keep at this temperature for 10 minutes to obtain a larger particle TATB suspension, filter, wash with water, and dry. TATB crystal particles with an average particle size of about 60 μm were obtained, and the appearance of large TATB particles was as follows figure 2 shown.

Embodiment 2

[0027] At room temperature, the submicron TATB (5g) with an average particle size of 500nm was added to dimethyl sulfoxide (300ml), the stirring speed was 200-400rpm, and the temperature was raised to 120°C at a speed of 3°C / min and maintained for 30 minutes. TATB is partially dissolved to obtain a TATB suspension, and then the temperature is lowered to 20°C at a rate of 1°C / min according to the temperature control program, and kept at this temperature for 10 minutes to obtain a larger particle TATB suspension, and then repeat the temperature rise and fall for 1 times, filtered, washed with water, and dried to obtain TATB crystal particles with an average particle size of about 80 μm.

Embodiment 3

[0029] At room temperature, TATB (5 g) with an average particle size of 10 μm was added to N,N-dimethylformamide (500 ml), the stirring speed was 100-300 rpm, and the temperature was raised to 100 ° C at a speed of 3 ° C / min and kept After 10 minutes, TATB was partially dissolved to obtain a TATB suspension, and then the temperature was lowered to 20°C at a rate of 1°C / min according to the temperature control program, and kept at this temperature for 10 minutes to obtain a larger particle TATB suspension, and then repeat The temperature was raised and lowered twice, filtered, washed with water, and dried to obtain TATB crystal particles with an average particle size of about 60 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com