Method for preparing formaldehyde-free non-ironing resin

A non-ironing resin and formaldehyde technology, applied in textiles and papermaking, fiber treatment, plant fiber, etc., can solve the problems of uneasy reaction, poor crosslinking, and low activity, and achieve good effect, small loss of fabric strength, and good use effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0026] (1) Add 72.5g glyoxal (40%) aqueous solution to a 250mL round-bottomed flask, adjust the pH value of the sodium hydroxide aqueous solution to 5-5.5, add 32g urea, stir and heat up to 45°C, keep the reaction for 4 hours, drop to 20°C, let stand for 12 hours, filter the solid, and dry in vacuum.

[0027] (2) Add 150g of absolute ethanol to a 500mL round-bottomed flask, add the above dried solid into ethanol, add 100g of epichlorohydrin after dissolving, adjust the pH value of the sodium hydroxide solution and maintain it at 11-12,45 ℃ heat preservation reaction for 5 hours, hydrochloric acid aqueous solution to adjust the pH = about 7, vacuum distillation to remove ethanol, add 150mL of water to obtain a formaldehyde-free non-iron resin solution.

preparation Embodiment 2

[0029] (1) Add 200g of glyoxal (40%) aqueous solution to a 500mL round bottom flask, adjust the pH value of the sodium carbonate aqueous solution to 5-5.5, add 85g of urea, heat up to 50°C, keep the reaction for 3 hours, and drop to 15°C , let stand for 8h, filter the solid, and dry in vacuum.

[0030] (2) Add 500g of absolute ethanol to a 1L round-bottomed flask, add the above-mentioned dried solids into ethanol, add 306g of glycidol after dissolving, adjust the pH value of the sodium hydroxide solution and maintain it at 10-11, and keep it warm at 50°C After reacting for 4 hours, adjust the pH of the aqueous hydrochloric acid solution to 6-7, distill off the ethanol under reduced pressure, and add 450 mL of water to obtain a formaldehyde-free, easy-care resin aqueous solution.

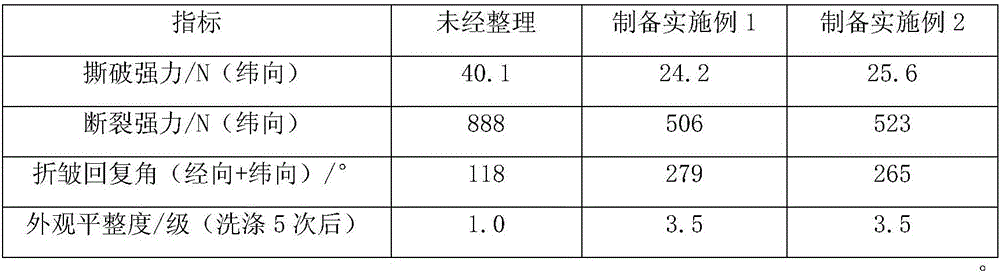

[0031] product testing:

[0032] The formaldehyde-free and easy-care resin solution prepared in Example 1-2 has an appearance of light yellow to brown transparent liquid without unpleasant odor, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com