Waterway system and water purifier

A waterway system and flow path technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, infiltration/dialysis water/sewage treatment, etc. The effect of prolonging the service life, prolonging the life time, and stable water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

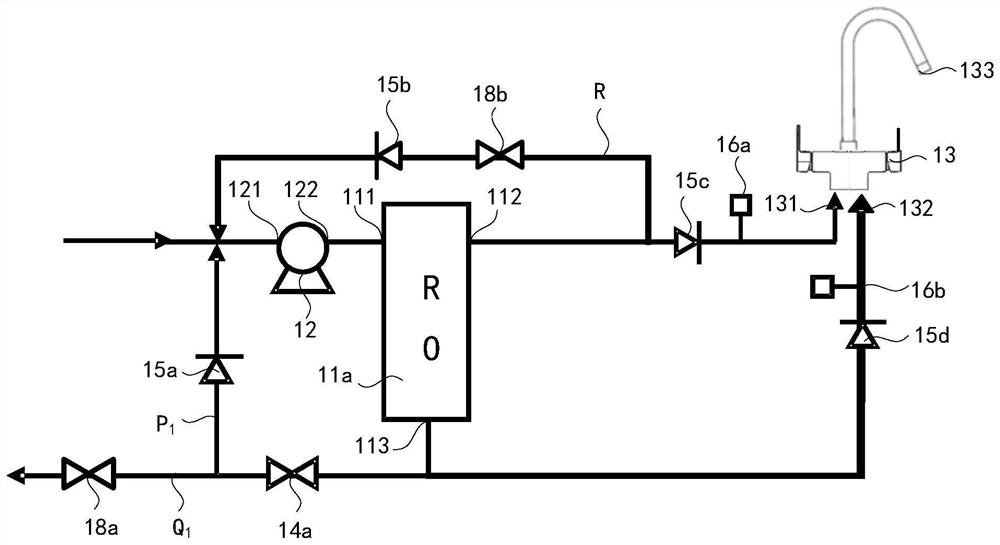

[0067] Example 1: Please refer to figure 1 . A mechanical double faucet is added to the waste water return system. The pure water outlet of the first reverse osmosis filter element 11a is divided into two lines, one of which is directly connected to the drinking water end of the double faucet. A high-voltage switch 16a, and the other is a pure water return pipeline R, which is used to return clean water to the front end of the first reverse osmosis filter element 11a; the waste water outlet of the first reverse osmosis filter element 11a is divided into two lines, and one line is directly connected to the life of the double faucet. The water ends are connected, and the fourth one-way valve 15d and the second high-pressure switch 16b are sequentially added to the pipeline; the other is the wastewater return pipeline, and the wastewater can return to the booster pump 12 through the first flow limiting valve 14a. There is a branch on the pipeline which is the first waste water d...

Embodiment 2

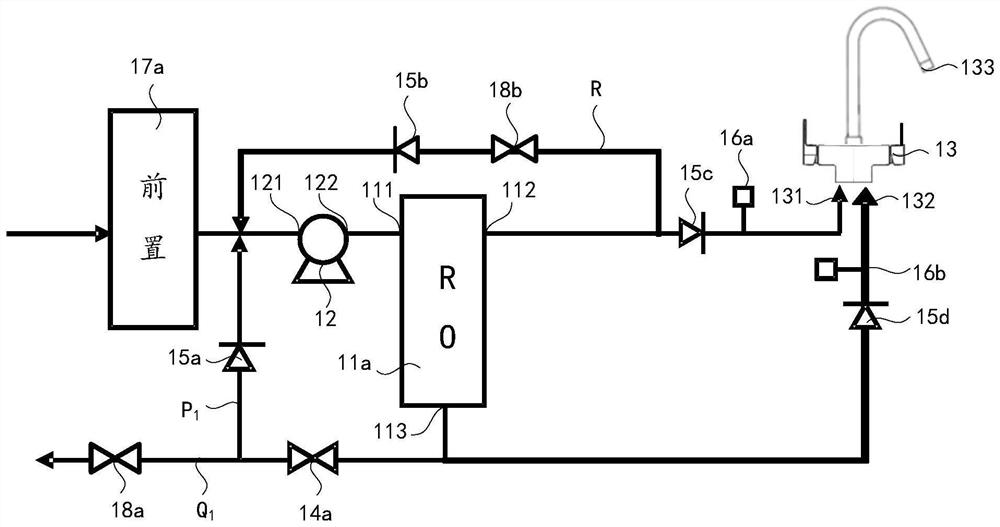

[0072] Example 2: Please refer to figure 2 . In this embodiment, on the basis of Embodiment 1, a pre-filter 17a is added at the front end of the booster pump 12. The type of the pre-filter 17a can be different forms of PP, different forms of activated carbon, ultrafiltration, nanofiltration and the above materials Composite filter elements, etc., the front outlet water flow rate is <8L / min.

[0073] The user opens the drinking water faucet (drinking water inlet 131 is connected to the outlet 133): the first high pressure switch 16a detects a pressure change, starts the booster pump 12, and starts water production; After a reverse osmosis filter element 11a, it is divided into one path of pure water and one path of waste water. The pure water is discharged from the drinking water faucet for drinking, and the waste water flows back to the front of the pump through the first flow limiting valve 14a and mixes with the front outlet water to enter the first reverse osmosis filter ...

Embodiment 3

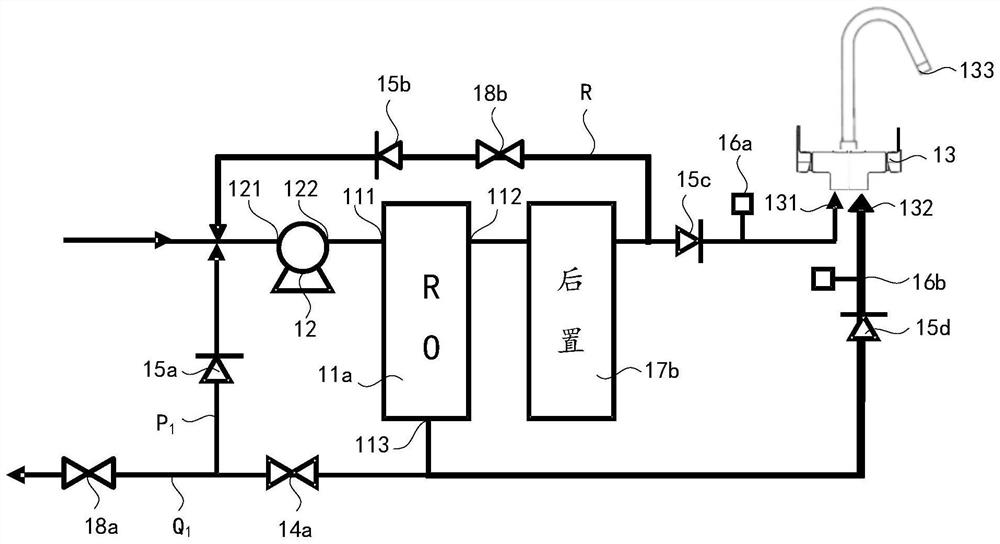

[0077] Example 3: Please refer to image 3 . In this embodiment, on the basis of Embodiment 1, a rear filter element 17b is added to the pure water outlet pipeline of the first reverse osmosis filter element 11a and before the pure water return pipeline. The type of the rear filter element 17b can be activated carbon in different forms.

[0078] The user opens the drinking water faucet (the drinking water inlet 131 is connected to the drain outlet 133): the first high pressure switch 16a detects a pressure change, starts the booster pump 12, and starts water production; after tap water flows into the first reverse osmosis filter element 11a, the One path of pure water and one path of waste water, the pure water passes through the post filter element 17b and is discharged from the drinking water faucet for drinking, the waste water flows back to the pump through the first flow limiting valve 14a, mixes with the tap water and enters the first reverse osmosis filter element 11a a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com