Preparation method for temperature-sensitive heavy-metal capturing agent

A heavy metal scavenger, heat-sensitive technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of incomplete precipitation, secondary pollution, low removal efficiency, etc. To achieve the effect of strong capture and sedimentation ability, not easy to secondary pollution, not easy to decompose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] It is a heat-sensitive polymer molecular brush prepared by the following steps:

[0032] Step 1 P(GMA-N 3 ) Synthesis of polymer backbone A

[0033] Take 1 part of ethyl 2-bromoisobutyrate initiator, 1000 parts of glycidyl methacrylate (GMA), 1000 parts of diphenyl ether, 5 parts of CuBr and 5 parts of N, N, N', N',N"-pentamethyldiethylenetriamine (PMDETA), ATRP reaction was carried out at 30°C under nitrogen protection for 9 hours to obtain polyglycidyl methacrylate (PGMA) with a degree of polymerization (DP) of 900;

[0034] Take 100 parts of PGMA (DP=900), 200 parts of NaN 3 and 300 parts of dimethylformamide (DMF), reacted at 60°C for 50 hours to obtain P(GMA-N 3 ), as polymer backbone A;

[0035] Step 2 Synthesis of two side chains

[0036] Synthesis of heat-sensitive polymer side chain C: take 1 part of propynyl bromoisobutyrate initiator, 300 parts of N-isopropylacrylamide (NIPAM), 100 parts of isopropanol and water (v / v,16 / 1), 2 parts of CuBr and 2 parts ...

Embodiment 2

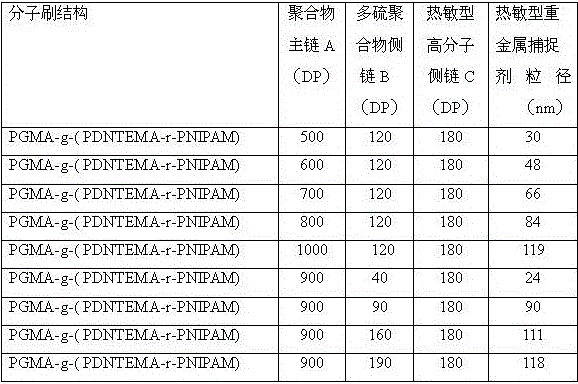

[0044] Preparation method and raw material composition are all the same as embodiment one, only for the polymer main chain A and polysulfide polymer side chain B of the thermosensitive polymer molecular brush PGMA-g-(PDNTEMA-r-PNIPAM) of embodiment one By adjusting the degree of polymerization, heat-sensitive heavy metal scavenger with different particle sizes can be prepared. The degree of polymerization of the polymer main chain A and the side chain B of the polysulfide polymer, and the particle size of the heat-sensitive heavy metal scavenger are shown in Table 1.

[0045] Polymers with a degree of polymerization of the polymer main chain A of 500, 600, 700, 800, 1000 and polymers with a degree of polymerization of the polysulfide polymer side chain B of 40, 90, 160, 190 and heat-sensitive polymer side chains C The degree of polymerization was 180. It can be prepared according to the method of Example 1 by controlling the raw materials or the polymerization reaction time. ...

Embodiment 3

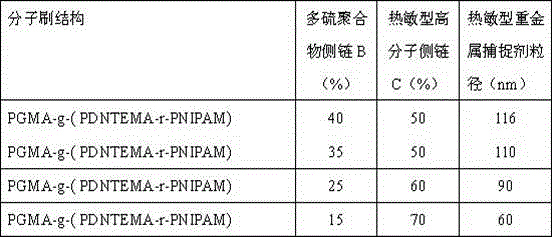

[0050] The preparation method and raw material composition are the same as in Example 1, only changing the grafting rate of the side chains of the thermosensitive polymer molecular brushes in Example 1, that is, the relative molar percentage of each side chain, can produce thermosensitive brushes with different particle sizes. heavy metal scavenger. See Table 2 for particle size variation.

[0051] Table 2: Effect of molecular brush side chain composition on the particle size of heat-sensitive heavy metal scavenger

[0052]

[0053] It can be seen from Table 2 that heat-sensitive heavy metal scavenger with different particle sizes can be prepared by changing the molar percentage of the grafting ratio of the side chain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com