LIP type nonionic surfactant, preparation method and applications thereof

A non-ionic surface and active agent technology, applied in the direction of chemical paint/ink remover, coating, etc., to achieve the effect of good appearance, strong capture and emulsification ability, and high whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) First add 2mol of isophorone diisocyanate (IPDI) into the reactor, and heat to 50°C at a stirring speed of 200r / min;

[0040] 2) Then slowly add 1 mol of lauric acid diethanolamide (LDEA) into the reactor at a drop rate of 6d / min at a stirring speed of 400r / min, and add 10mL of chloroform for viscosity reduction, and continue to Stir and keep warm for 60 minutes;

[0041] 3) Add 2mol PEG-400 into the reactor quickly within 5s at a stirring speed of 200r / min, continue to react at a reaction temperature of 60°C for 90min until the end of the reaction, and then cool down to room temperature to obtain a LIP type nonionic Surfactant (n=9 in molecular formula).

[0042] The LIP type nonionic surfactant prepared in Example 1 is used alone as a deinking agent for waste paper deinking, and is denoted as LIP-1.

Embodiment 2

[0044] 1) First add 2mol of isophorone diisocyanate (IPDI) into the reactor, and heat to 55°C at a stirring speed of 250r / min;

[0045] 2) Then slowly add 1 mol of lauric acid diethanolamide (LDEA) into the reactor at a drop rate of 10d / min at a stirring speed of 450r / min, and add 12mL of chloroform for viscosity reduction, and continue to Stir and keep warm for 90min;

[0046] 3) Add 2mol PEG-600 into the reactor quickly within 20s at a stirring speed of 250r / min, continue the reaction at a reaction temperature of 70°C for 120min until the end of the reaction, and then lower it to room temperature to obtain a LIP type nonionic Surfactant.

[0047] The LIP type nonionic surfactant prepared in Example 2 is used alone as a deinking agent for waste paper deinking, and is denoted as LIP-2.

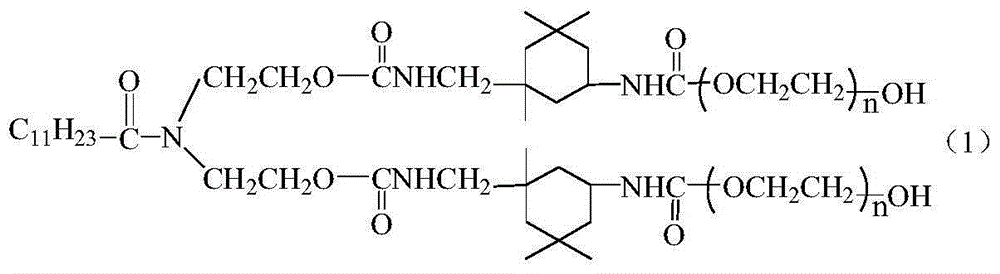

[0048] The molecular structural formula of LIP-2 is shown in formula (1),

[0049]

[0050] where n=13.

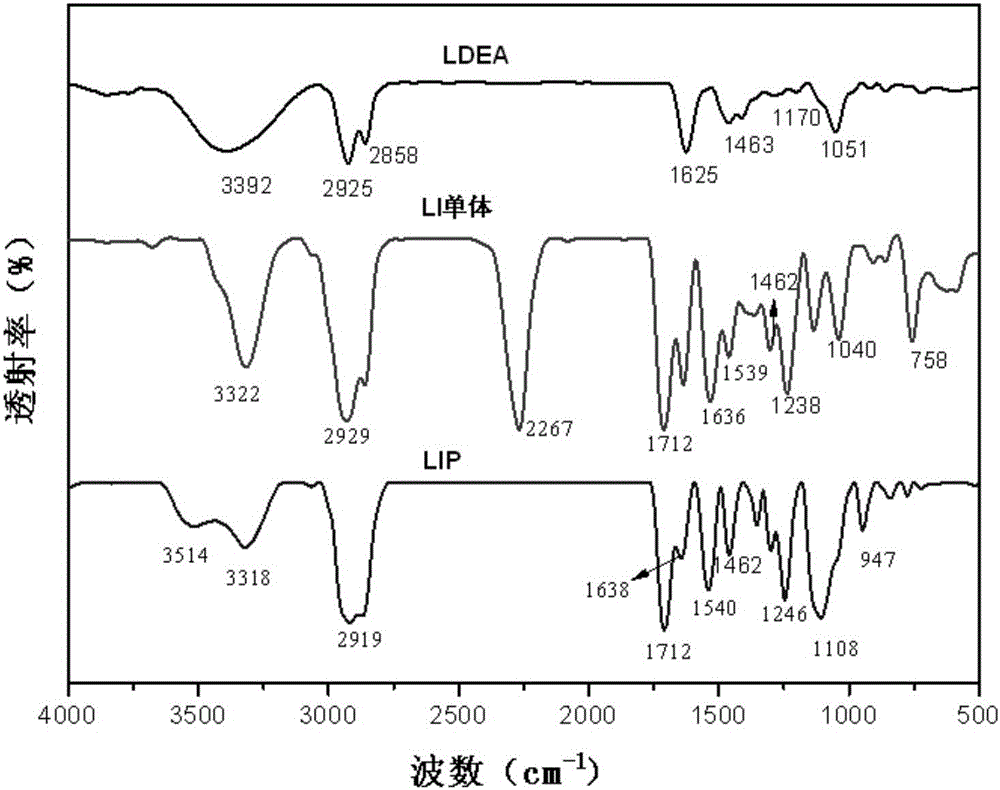

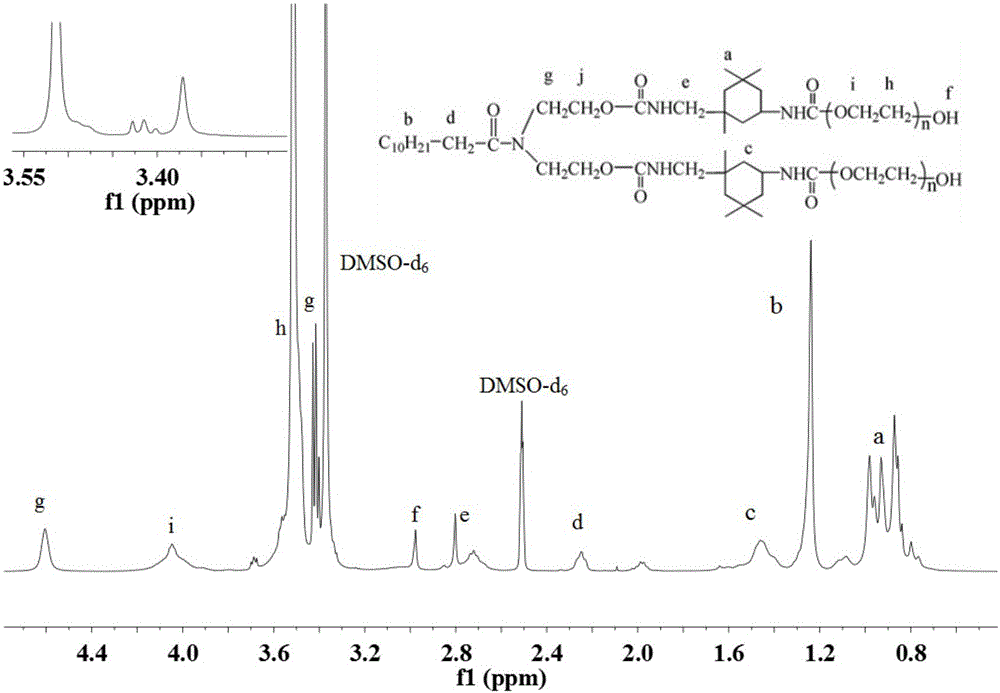

[0051] IR and 1 H-NMR analysis

[0052] 1. The infrared spectrum of LIP-2

...

Embodiment 3

[0057] 1) First add 2mol of isophorone diisocyanate (IPDI) into the reactor, and heat to 55°C at a stirring speed of 300r / min;

[0058] 2) Then at a stirring speed of 500r / min, slowly add 1 mol of lauric acid diethanolamide into the reactor at a dropping speed of 6d / min, and add 15mL of chloroform to reduce the viscosity, continue to stir and keep warm after the dropping Reaction 120min;

[0059] 3) Add 2mol PEG-600 into the reactor quickly within 5s at a stirring speed of 300r / min, continue the reaction at a reaction temperature of 90°C for 150min until the end of the reaction, and then lower it to room temperature to obtain a LIP-type nonionic Surfactant.

[0060] The LIP type nonionic surfactant prepared in Example 3 is used alone as a deinking agent for waste paper deinking, and is denoted as LIP-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com