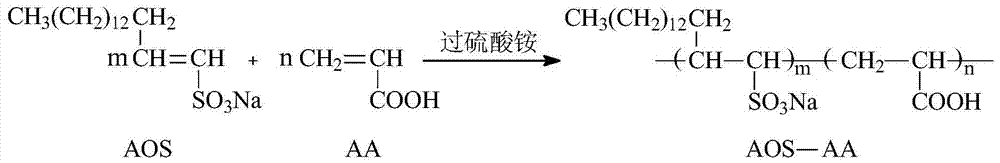

A kind of aos-aa binary copolymer surfactant and its preparation method and application

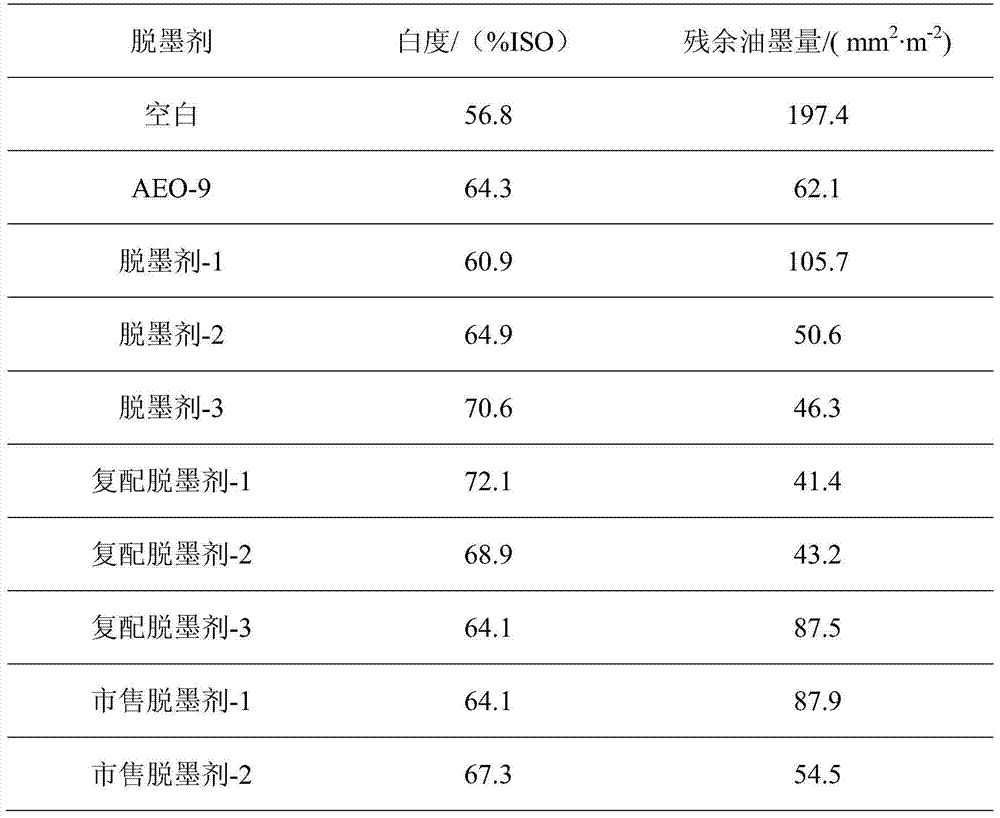

A technology of surfactant and binary copolymer, which is applied in the field of waste paper deinking, can solve the problem of less copolymer deinking agent, and achieve the effects of less residual ink, good deinking effect and high whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Reaction raw material: the initiator ammonium persulfate of 3.0% of the initiator ammonium persulfate that is the monomer α-olefin sulfonate of 1:1 and monomer acrylic acid, the monomer gross mass in molar ratio, and the balance is deionized water (reaction medium), wherein reaction The mass percentage concentration of monomer sodium α-olefin sulfonate in the system is 12%.

[0029] Steps: first filter the monomer α-olefin sulfonate sodium to remove impurities, and adjust to neutrality with a 20% NaOH solution, then use deionized water as the reaction medium, and deionized water, half of the monomer α- Sodium olefin sulfonate (AOS) and half of the monomeric acrylic acid (AA) were put into a three-necked flask at 85°C, and the rest of the AOS and AA were added after 1 hour, and when AOS and AA were added to the three-necked flask for the first time, it started Continuously and slowly add the initiator ammonium persulfate into the three-necked flask dropwise for 1.5 hours...

Embodiment 2

[0036] Reaction raw material: the initiator ammonium persulfate of 1.5% of the initiator ammonium persulfate that is the monomer α-olefin sulfonate of 1:2 and monomer acrylic acid, monomer gross mass, the balance is deionized water (reaction medium), wherein reaction The mass percentage concentration of monomer sodium α-olefin sulfonate in the system is 12%.

[0037] Steps: first filter the monomer α-olefin sulfonate sodium to remove impurities, and adjust to neutrality with a 20% NaOH solution, then use deionized water as the reaction medium, and deionized water, half of the monomer α- Sodium olefin sulfonate (AOS) and half of the monomeric acrylic acid (AA) were put into a three-necked flask at 85°C, and the rest of the AOS and AA were added after 1 hour, and when AOS and AA were added to the three-necked flask for the first time, it started Continuously and slowly add the initiator ammonium persulfate into the three-necked flask dropwise for 1.5 hours, and stir the reaction...

Embodiment 3

[0039] Reaction raw material: the initiator ammonium persulfate of 3.0% initiator ammonium persulfate that is the monomer α-olefin sulfonate of 1:2 and monomer acrylic acid, the monomer gross mass in molar ratio, and the remainder is deionized water (reaction medium), wherein reaction The mass percentage concentration of monomer sodium α-olefin sulfonate in the system is 12%.

[0040] Steps: first filter the monomer α-olefin sulfonate sodium to remove impurities, and adjust to neutrality with a 20% NaOH solution, then use deionized water as the reaction medium, and deionized water, half of the monomer α- Sodium olefin sulfonate (AOS) and half of the monomeric acrylic acid (AA) were put into a three-necked flask at 85°C, and the rest of the AOS and AA were added after 1 hour, and when AOS and AA were added to the three-necked flask for the first time, it started Continuously and slowly add the initiator ammonium persulfate into the three-necked flask dropwise for 1.5 hours, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com