A kind of low-shrinkage micro-foamed polypropylene and preparation method thereof

A foamed polypropylene, low-shrinkage micro technology, applied in the field of modified plastics, can solve problems such as pressure drop, and achieve the effect of eliminating air marks and reducing the weight of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

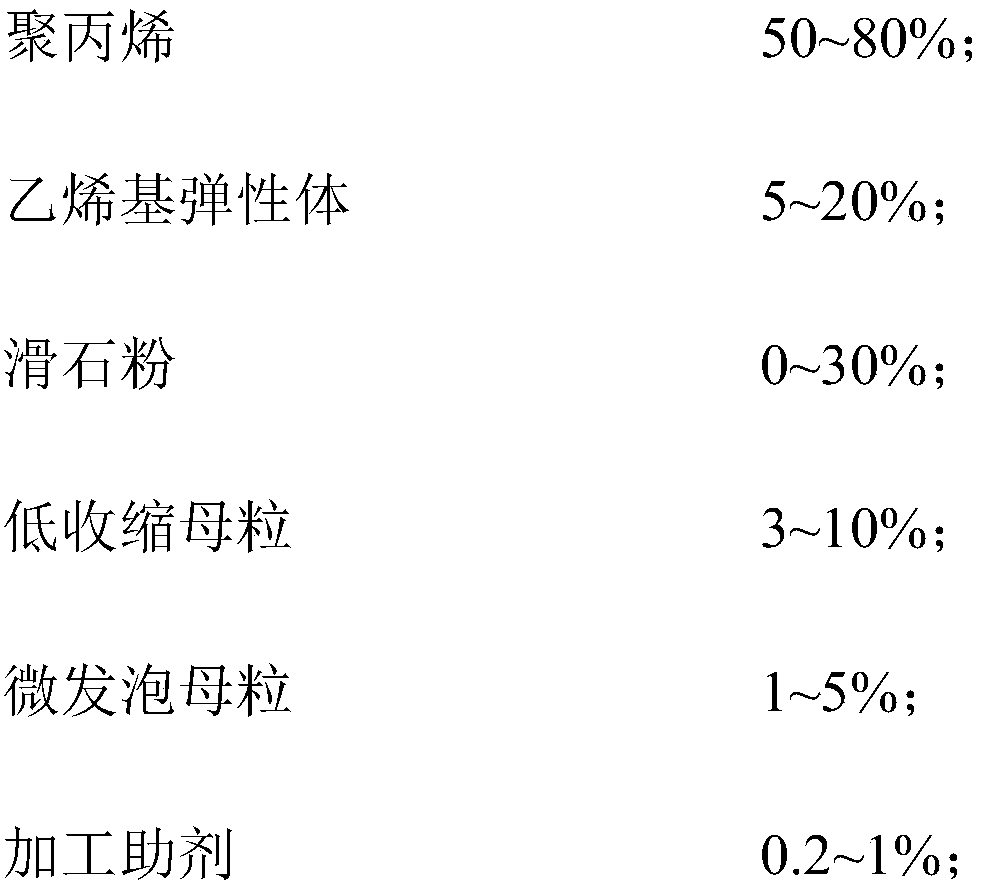

Method used

Image

Examples

Embodiment 1

[0026] A low-shrinkage micro-foamed polypropylene, which is composed of the following raw material components by weight percentage: 63% polypropylene, 10% vinyl elastomer, 10% talcum powder, 5% low-shrinkage masterbatch, micro-foamed masterbatch Granules 2%, processing aid 0.6%.

[0027] The polypropylene is copolymerized polypropylene BX3920. The said vinyl elastomer is ethylene-octene copolymer (POE 8842). The mesh number of described talcum powder is 3000 mesh. The low-shrinkage masterbatch is a reaction extrusion product of 50% copolymerized polypropylene EP548R, 50% high-impact polystyrene (PH88) and 0.8% peroxide (double 25). The micro-foaming masterbatch is an extrusion product of 30% sodium bicarbonate foaming agent, 20% linear low-density polyethylene (LLDPE 7144) and 50% EPDM rubber (EPDM 4770R). The processing aid is composed of an antioxidant and a weather-resistant agent, wherein the antioxidant is composed of two compounds of 0.2% hindered phenolic antioxidant...

Embodiment 2

[0044] A low-shrinkage micro-foamed polypropylene, which is composed of the following raw material components by weight percentage: 55% polypropylene, 10% vinyl elastomer, 20% talcum powder, 10% low-shrinkage masterbatch, micro-foamed masterbatch Granules 5%, processing aid 0.6%.

[0045] The polypropylene is copolymerized polypropylene BX3920. The said vinyl elastomer is ethylene-octene copolymer (POE 8842). The mesh number of described talcum powder is 3000 mesh. The low-shrinkage masterbatch is a reaction extrusion product of 50% copolymerized polypropylene EP548R, 50% high-impact polystyrene (PH88) and 0.8% peroxide (double 25). The micro-foaming masterbatch is an extrusion product of 20% sodium bicarbonate foaming agent, 20% linear low-density polyethylene (LLDPE 7144) and 60% EPDM rubber (EPDM4770R). The processing aid is composed of an antioxidant and a weather-resistant agent, wherein the antioxidant is composed of two compounds of 0.2% hindered phenolic antioxidant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com