An electrolytic polishing method for complex brass

An electrolytic polishing, complex brass technology, applied in the field of electrolytic polishing solution and electrolytic polishing, can solve the problems of unstable mechanical polishing quality, low efficiency, over-corrosion of complex brass, etc., to reduce the experimental work intensity, simple formula, The effect of a good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

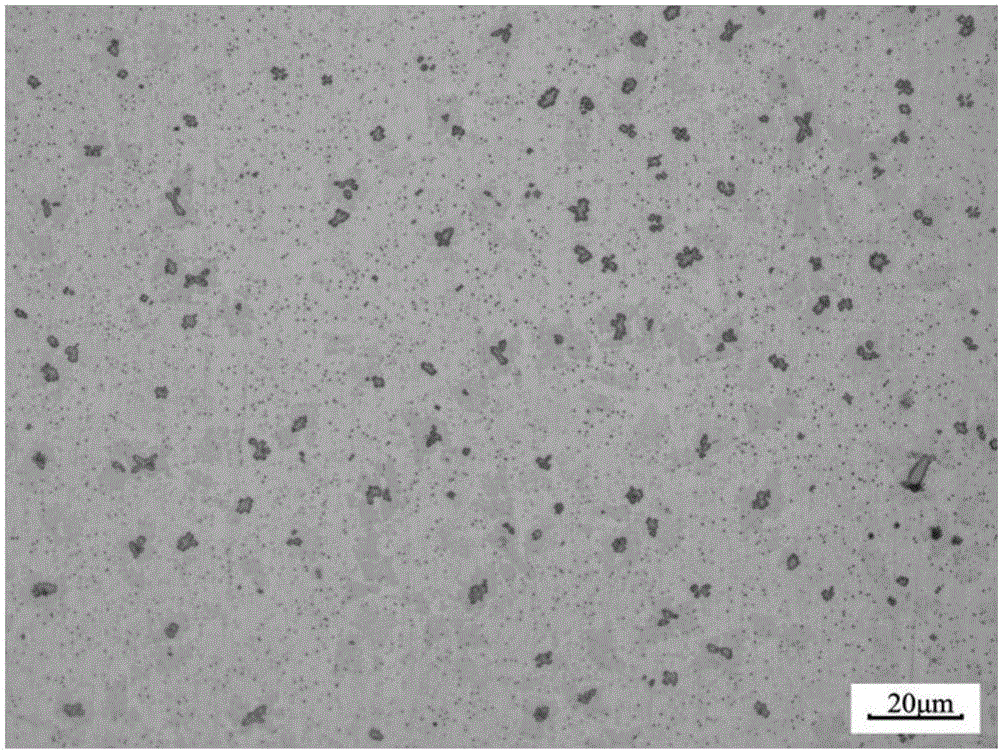

[0046] 1. The selected sample is cast complex aluminum brass, the chemical composition (mass percentage) is: 64.76% Cu, 22.27% Zn, 1.92% Fe, 7.49% Al, 2.51% Mn, 0.22% Pb, 0.52% Ni;

[0047] 2. Grind the metallographic sample in the order of 400#, 800#, 1500#, 2500#, 5000# sandpaper. When changing the sandpaper, the grinding direction of the sample should be changed to π / 2, and there is no upper A wear mark of sandpaper, the lubricant is water;

[0048] 3. Mechanical polishing can be done according to the general metallographic sample polishing process, using short woolen cloth, 0.3μmAl 2 o 3 The polishing paste and the lubricant are water, the rotational speed of the polishing disc is 300r / min, and the surface is polished until there are no scratches visible to the naked eye. During the polishing process, attention should be paid to the lighter the force at the later stage of polishing, and the direction of the sample should be kept unchanged during the polishing process to ...

Embodiment 2

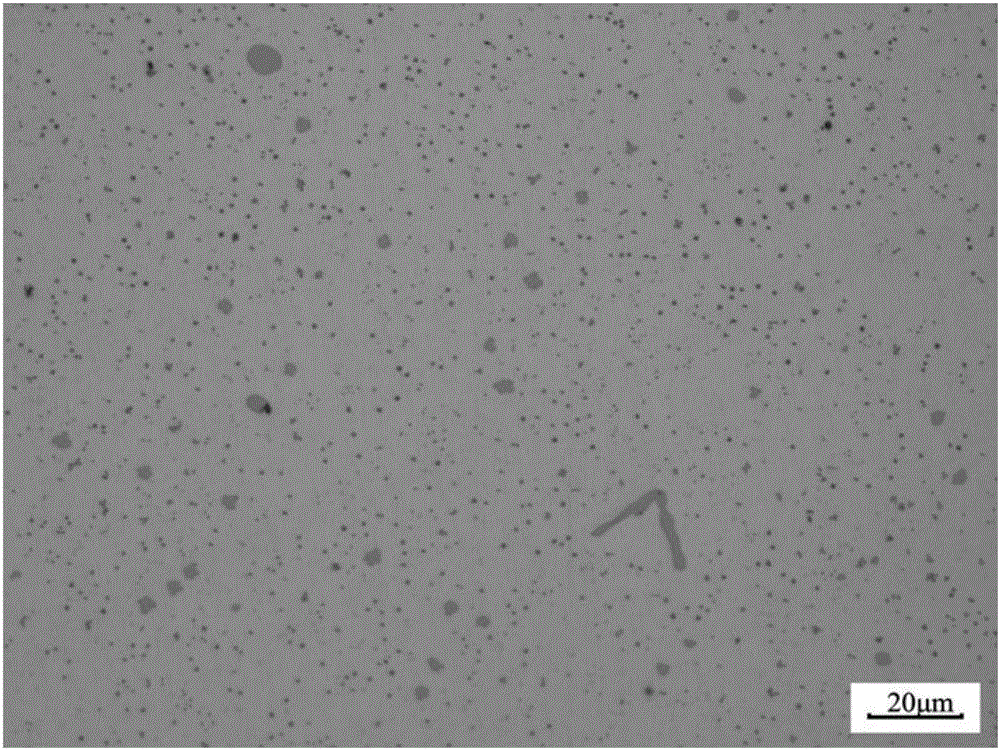

[0052] 1. The selected sample is normalized complex aluminum brass, the chemical composition (mass percentage) is: 64.76% Cu, 22.27% Zn, 1.92% Fe, 7.49% Al, 2.51% Mn, 0.22% Pb, 0.52% Ni ;

[0053] 2. Grind the metallographic sample in the order of 400#, 800#, 1500#, 2500#, 5000# sandpaper. When changing the sandpaper, the grinding direction of the sample should be changed to π / 2, and there is no upper A wear mark of sandpaper, the lubricant is water;

[0054] 3. Mechanical polishing can be done according to the general metallographic sample polishing process, using short woolen cloth, 0.3μm Al 2 o 3 The polishing paste and the lubricant are water, the rotational speed of the polishing disc is 300r / min, and the surface is polished until there are no scratches visible to the naked eye. During the polishing process, attention should be paid to the lighter the force at the later stage of polishing, and the direction of the sample should be kept unchanged during the polishing pr...

Embodiment 3

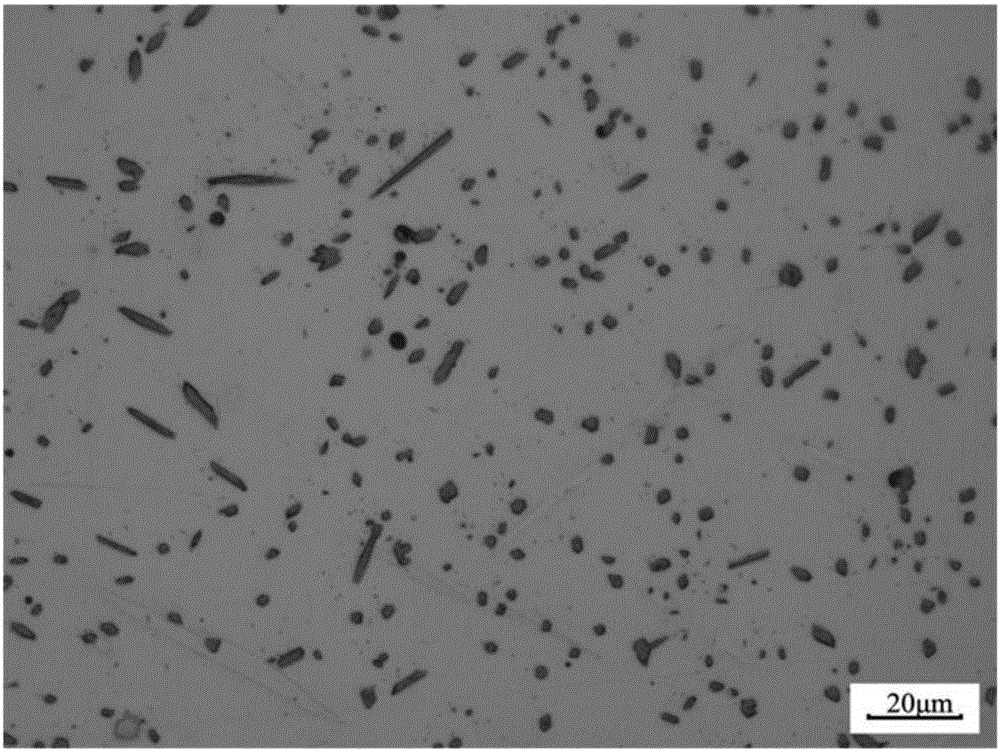

[0058] 1. The selected sample is as-cast complex manganese brass, the chemical composition (mass percentage) is: 60.28% Cu, 33.3% Zn, 0.29% Fe, 2.09% Al, 1.96% Mn, 1.05% Si, 0.43% Pb;

[0059] 2. Grind the metallographic sample in the order of 400#, 800#, 1500#, 2500#, 5000# sandpaper. When changing the sandpaper, the grinding direction of the sample should be changed to π / 2, and there is no upper A wear mark of sandpaper, the lubricant is water;

[0060] 3. Mechanical polishing can be done according to the general metallographic sample polishing process, using short woolen cloth, 0.3μm Al 2 o 3 The polishing paste and the lubricant are water, the rotational speed of the polishing disc is 300r / min, and the surface is polished until there are no scratches visible to the naked eye. During the polishing process, attention should be paid to the lighter the force at the later stage of polishing, and the direction of the sample should be kept unchanged during the polishing process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com