Steam water heat recovery and fuel heating integrated efficiency-increasing system for combined-cycle power plant

A combined cycle and fuel heating technology, applied in turbine/propulsion fuel delivery system, fuel heating of turbine/propulsion device, charging system, etc., can solve the problem of reducing steam turbine steam cycle efficiency, limited improvement of combined cycle thermal efficiency, and its auxiliary system explosion, etc., to achieve the effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

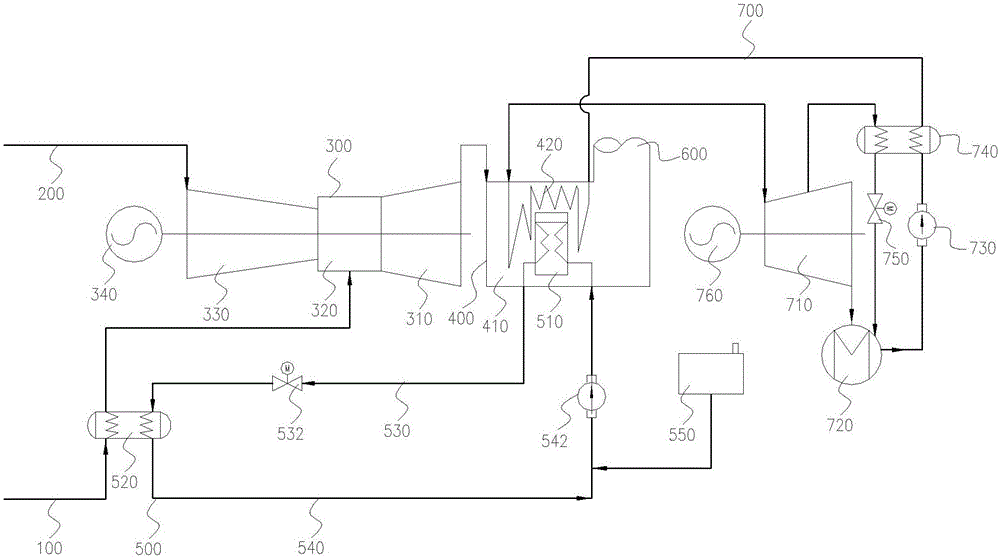

[0028] Such as figure 1 As shown, a steam-water recovery and fuel heating integrated efficiency improvement system of a combined cycle power plant includes a gas turbine unit 300, an intake pipe 200 and a feed pipe 100 connected to the gas turbine unit 300, and the gas turbine unit The waste heat boiler 400 connected to the outlet of 300 , the chimney 600 connected to the waste heat boiler 400 , and the steam unit 700 connected to the waste heat boiler 400 . The gas-steam combined cycle power plant uses the gas turbine unit 300 and the steam unit 700 as the host, supplies air and fuel to the gas turbine unit through the intake pipe 200 and the feed pipe 100, and mixes the air and fuel in the gas turbine unit 300 for combustion , using the generated flue gas to generate electricity. At the same time, the exhaust smoke after the work of the gas turbine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com