Method for testing surface hardness of composite insulating material

A technology of composite insulation and surface hardness, which is applied in the direction of material analysis, material excitation analysis, and material analysis through optical means, which can solve the problems of limited measurement accuracy and achieve the effects of convenient operation, safe operation, and fast analysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

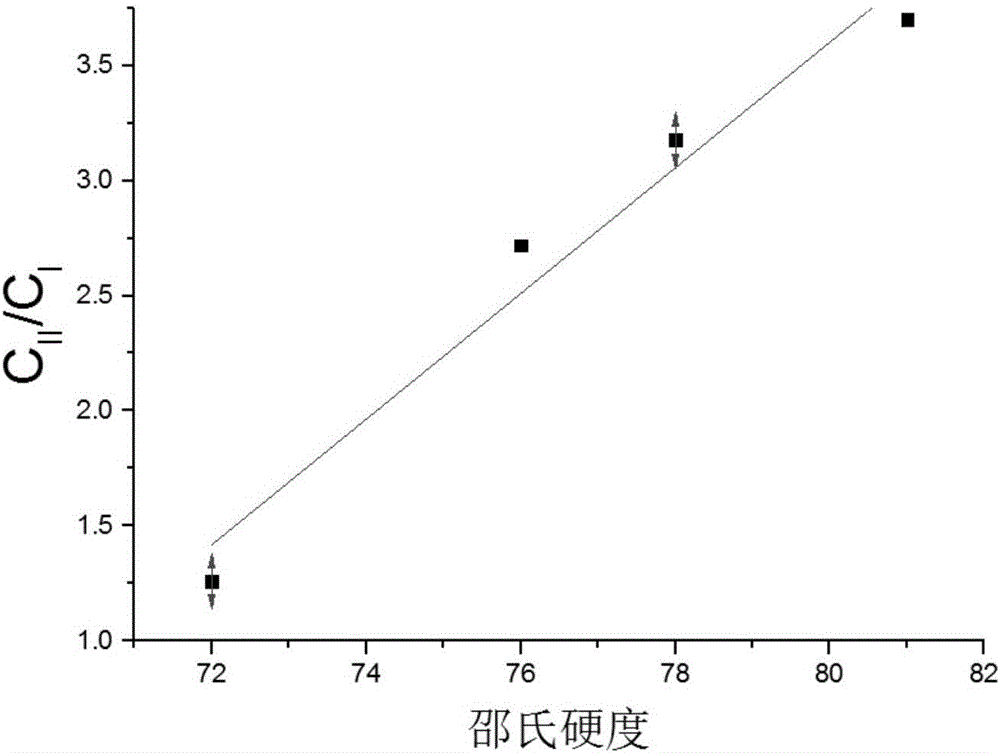

[0063] Sampling composite insulator sheds of 220kV transmission lines, the same manufacturer, and different operating regions, and measuring the Shore hardness x at specific locations i , carry out the laser-induced breakdown spectrum test at a distance of 5m for each specific position, select the ion line C II 588.977nm and the atomic line C I 247.8561nm of carbon element, and calculate their ratio y i , program in the software to calculate its y i with x i relationship such as figure 1 shown. Use LIBS test for other positions to be tested to obtain their spectral data, and use this functional relationship to calculate the hardness values of other positions to be tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com