Preparation apparatus and method of ultra-low roughness tungsten probe

A preparation device and roughness technology, which is applied in the field of preparation devices for ultra-low roughness tungsten probes, can solve problems such as high stability requirements, increased corrosion system construction costs, and inability to accurately control the length-to-diameter ratio. Easy to operate and prevent excessive corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

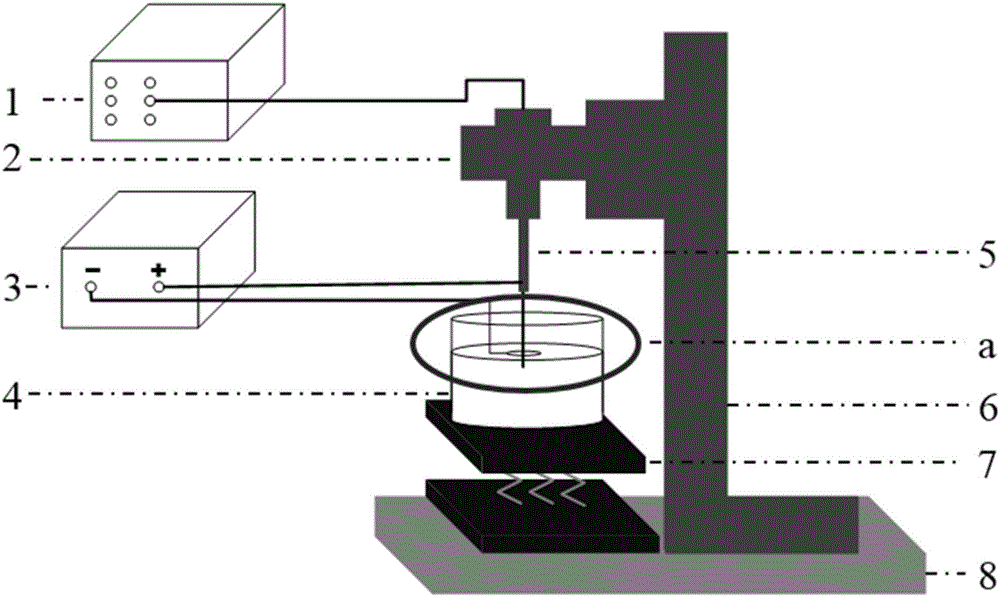

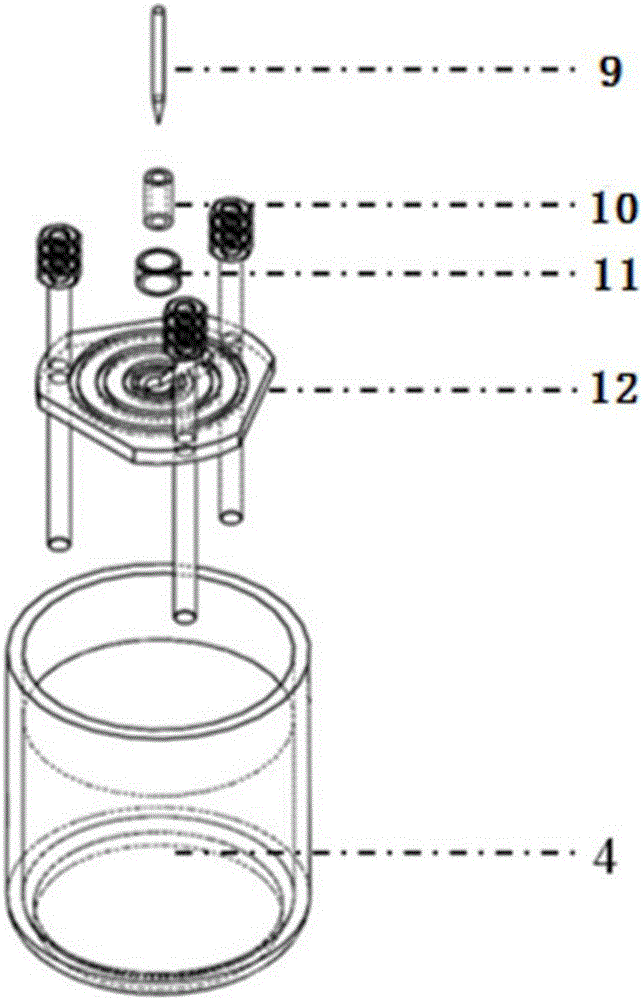

[0033] A preparation device for an ultra-low roughness tungsten probe, comprising a shock absorbing platform 8, the shock absorbing platform 8 is an optical shock absorbing flat plate, the shock absorbing platform 8 is connected with an L-shaped fixing bracket 6, and the L-shaped fixing bracket 6 is connected with a useful For the motion control system that drives the tungsten wire 9 to move, the motion control system includes a track that is arranged on the L-shaped fixed bracket 6 and is perpendicular to the shock-absorbing platform 8. A slider is arranged in the track, and a slider is connected to the slider for driving the slider along the track. The stepping motor 2 of the orbital motion, the tungsten wire 9 is connected to the bottom of the stepping motor 2 through the tungsten wire clamp 5, the container 4 containing the corrosive solution is also arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com