Display substrate and driving method thereof and display device

A technology for displaying substrates and display areas, which is applied in the direction of instruments, semiconductor devices, circuits, etc., and can solve problems such as increased thickness of display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

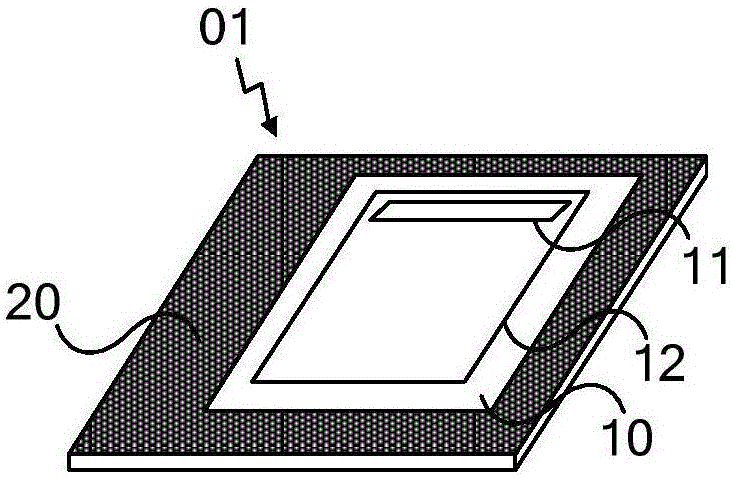

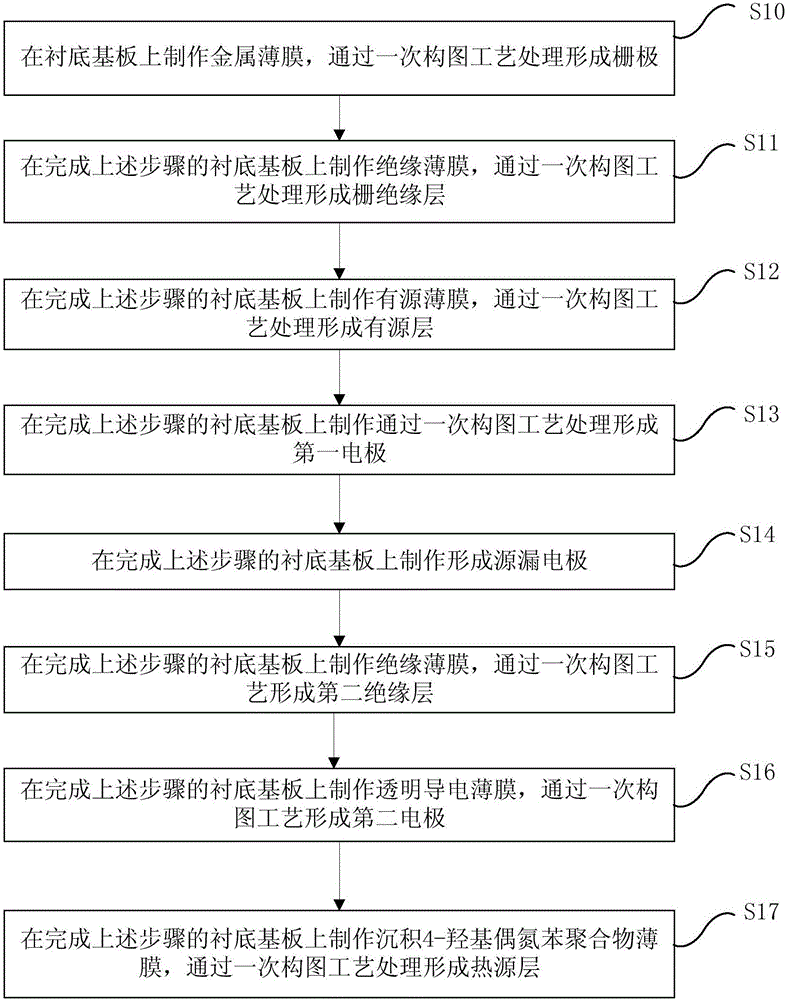

[0048] Embodiment 1. In this embodiment, the array substrate includes a plurality of sub-pixels arranged in a matrix. In this case, the position of the heat source layer 12 corresponds to the light-transmitting area of the sub-pixel, and the pattern of the heat source layer 12 is consistent with the shape of the light-transmitting area. The following is the preparation method of the array substrate, such as image 3 Shown include:

[0049] Step S10, such as Figure 4a As shown, the gate 102 is formed on the base substrate 101 through a patterning process.

[0050] Specifically, a metal thin film may be prepared on the base substrate 101 first. The gate 102 is then formed through a patterning process. Wherein, the gate 102 is made of a metal material, and the metal material can generally be metals such as molybdenum, aluminum, aluminum-nickel alloy, molybdenum-tungsten alloy, chromium, or copper, or a combination structure of the above-mentioned thin films.

[0051] It s...

Embodiment 2

[0069] Embodiment 2 In this embodiment, when the display substrate 01 is an array substrate, the pattern of the heat source layer 12 is consistent with the shape of the display area 10 of the display substrate 01 . The preparation method of the array substrate is as follows, including:

[0070] Such as Figure 8a As shown, the preparation method of forming the gate 102, the first insulating layer 103, the active layer 104, the pixel electrode 105, the source and drain electrodes 106, the second insulating layer 107, and the common electrode 108 on the base substrate 101 in sequence is the same as the above step S10 - The step S16 is the same and will not be repeated here. The difference is: on the base substrate 101 formed with the common electrode 108, a patterning process such as Figure 8a The heat source layer 12 is shown.

[0071] In this embodiment, the heat source layer 12 is located in the display area 10 and conforms to the shape of the display area 10 . Since the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com