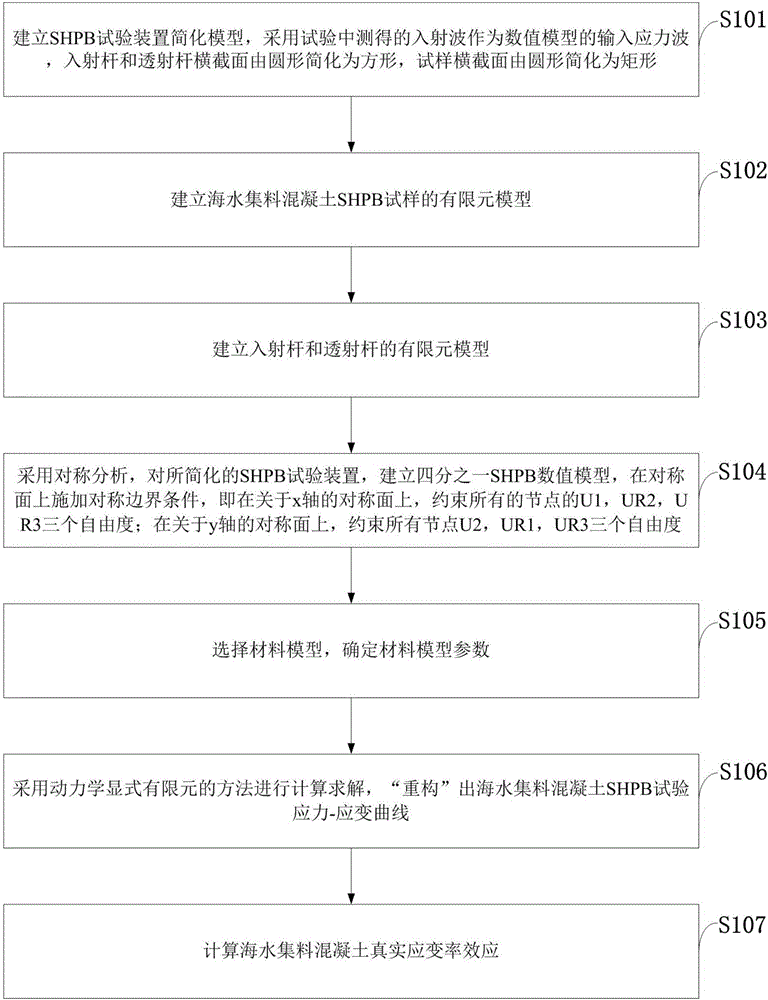

Computer dynamic simulation method of determining true strain rate effect of seawater aggregate concrete

A real strain and dynamic simulation technology, applied in design optimization/simulation, calculation, special data processing applications, etc., to achieve the effect of avoiding the increase of compressive strength, fast results, and good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1, matrix strength 70.5Mpa, theoretical porosity 10% seawater aggregate concrete:

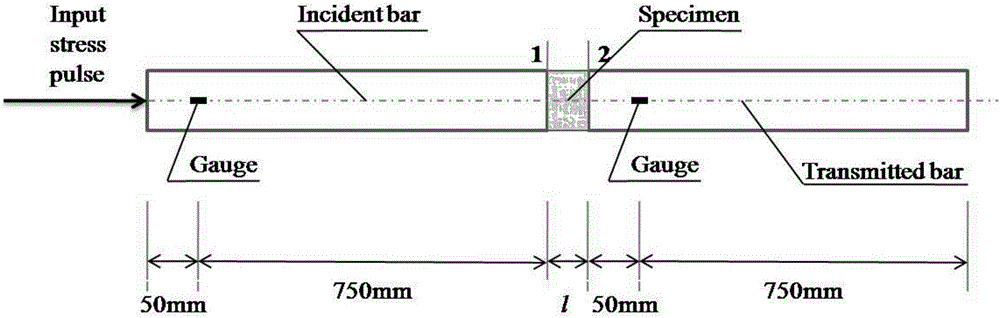

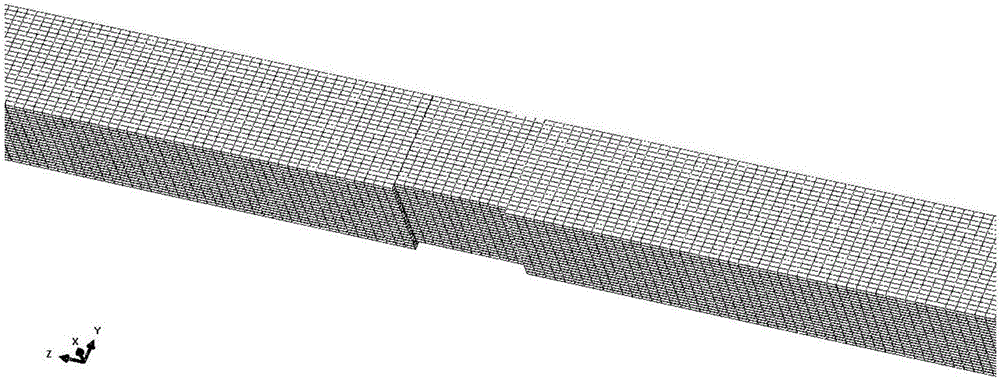

[0069] Calculate the "reconstructed" stress-strain curves of seawater aggregate concrete with a theoretical porosity of 10% at three strain rate levels of 70 / s, 100 / s and 140 / s, Figure 5 is the measured incident stress wave corresponding to the three strain rate levels; the basic physical parameter density of the incident rod and the transmitted rod is 7850kg / m 3 , modulus of elasticity 210GPa, Poisson's ratio 0.3, compressive strength 400MPa; basic physical parameters density of seawater aggregate concrete matrix 2172kg / m 3 , Elastic modulus 24.2GPa, Poisson's ratio 0.21; seawater aggregate concrete matrix friction angle β=46°, expansion angle ψ=β=46°, off-plane parameter K=1; Figure 6 It is a structured grid of one eighth cell of seawater aggregate concrete with a theoretical porosity of 10%, and the cell size is 8.7656mm×8.7656mm×8.7656mm, Figure 7 It is a quarter structu...

Embodiment 2

[0071] Embodiment 2, matrix strength 70.5Mpa, theoretical porosity 20% seawater aggregate concrete:

[0072] Calculate the "reconstructed" stress-strain curves of seawater aggregate concrete with a theoretical porosity of 20% at three strain rate levels of 70 / s, 100 / s and 140 / s, Figure 9 is the measured incident stress wave corresponding to the three strain rate levels; the basic physical parameter density of the incident rod and the transmitted rod is 7850kg / m 3 , modulus of elasticity 210GPa, Poisson's ratio 0.3, compressive strength 400MPa; basic physical parameters density of seawater aggregate concrete matrix 2172kg / m 3 , Elastic modulus 24.2GPa, Poisson's ratio 0.21; seawater aggregate concrete matrix friction angle β=46°, expansion angle ψ=β=46°, off-plane parameter K=1; Figure 10 It is a structured grid of one-eighth cell of seawater aggregate concrete with a theoretical porosity of 20%, and the cell size is 7.000mm×6.8930mm×6.8930mm, Figure 11 The theoretical por...

Embodiment 3

[0074] Example 3, the matrix strength is 70.5Mpa, the theoretical porosity is 30% seawater aggregate concrete:

[0075] Calculate the "reconstructed" stress-strain curves of seawater aggregate concrete with a theoretical porosity of 30% at three strain rate levels of 70 / s, 100 / s and 140 / s, Figure 13 is the measured incident stress wave corresponding to the three strain rate levels; the basic physical parameter density of the incident rod and the transmitted rod is 7850kg / m 3 , modulus of elasticity 210GPa, Poisson's ratio 0.3, compressive strength 400MPa; basic physical parameters density of seawater aggregate concrete matrix 2172kg / m 3 , Elastic modulus 24.2GPa, Poisson's ratio 0.21; seawater aggregate concrete matrix friction angle β=46°, expansion angle ψ=β=46°, off-plane parameter K=1; Figure 14 It is a structured grid of one-eighth cell of seawater aggregate concrete with a theoretical porosity of 30%, and the cell size is 5.9033mm×6.1667mm×6.1667mm, Figure 15 It is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com