Reactor for synthesizing vinyl chloride through acetylene method

A reactor, vinyl chloride technology, applied in hydrogen halide addition preparation, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of loss of control of reaction temperature, affecting synthesis effect, flying temperature, etc., to achieve heat dissipation effect and Good corrosion resistance, improved product quality, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

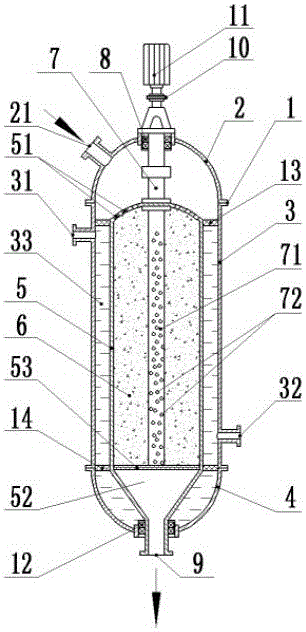

[0037] like figure 1 As shown, a reactor for synthesizing vinyl chloride by acetylene method includes a reactor body 1, a reaction mechanism and a cooling mechanism; the reactor body 1 is provided with an air inlet 21 and an air outlet 9; inside the reactor body 1 is a reaction mechanism; the reactor body 1 is also provided with a cooling mechanism; the reactor body 1 is formed by connecting the upper casing 2, the cylinder body 3 and the lower casing 4; the upper casing 2, the cylinder body 3 and the lower casing 4 are connected from the upper Connected sequentially from bottom to bottom, the cooling mechanism is located between the reactor body 1 and the reaction mechanism; a rotating device is also connected to the reaction mechanism.

[0038]The reaction mechanism includes a reaction cylinder 5 and a catalyst 6; the catalyst 6 is filled in the entire reaction cylinder 5; the reaction cylinder 5 is erected in the cylinder body 3 through a partition. There are several air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com