Welding method for doping trace boron element into weld metal

A technology of weld metal and welding method, which is applied in the field of welding metallurgy and alloying, to achieve the effect of improving the level of toughness, improving toughness and improving service safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] According to the metallurgical method of the present invention, the matching manual electrode design for 12MnCrNi steel is implemented. According to the technical requirements of the 12MnCrNi steel matching manual welding rod (see Table 1), design and make three batches of 12MnCrNi steel matching manual welding rods containing borax (sodium tetraborate, Na2B4O7. Middle), the composition of the steel core and coating powder used in the three batches of electrodes are shown in Table 2 and 3, respectively. The base metal and welding process parameters of the three batches of electrodes are shown in Table 4. After welding, the mechanical properties of the deposited metal were tested, and the test results are shown in Table 5. As a comparison, see Table 6 for the test data of 12MnCrNi steel supporting manual electrodes that do not contain borides on the original drug skin.

Embodiment ——12

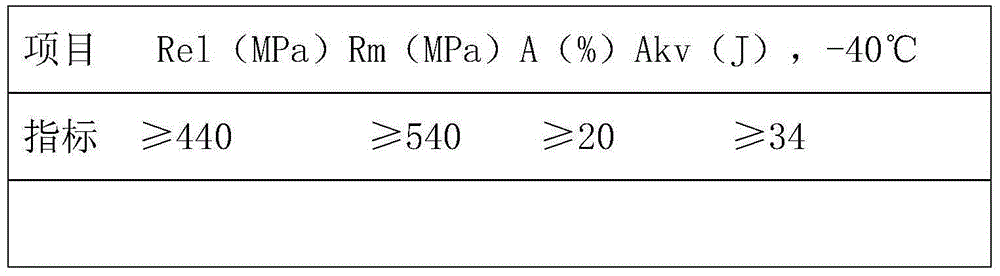

[0014] Table 1 embodiment - technical requirements for 12MnCrNi steel supporting manual welding rod

[0015] Deposited Metal Mechanical Properties

[0016]

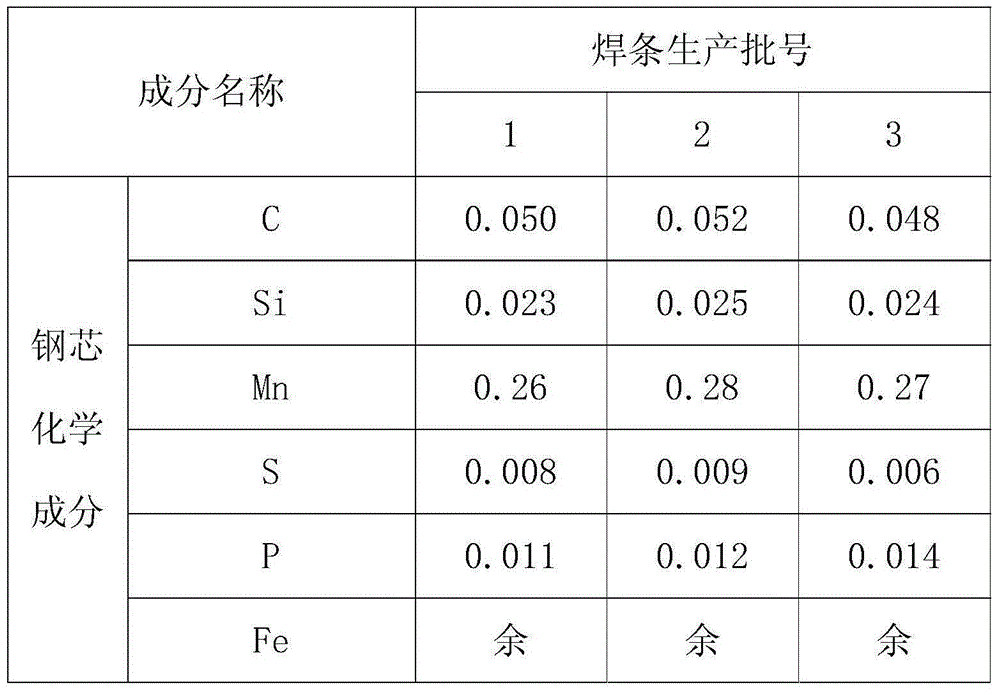

[0017] Table 2 embodiment——12MnCrNi steel matching manual electrode steel core composition (weight, %) (specification 4mm)

[0018]

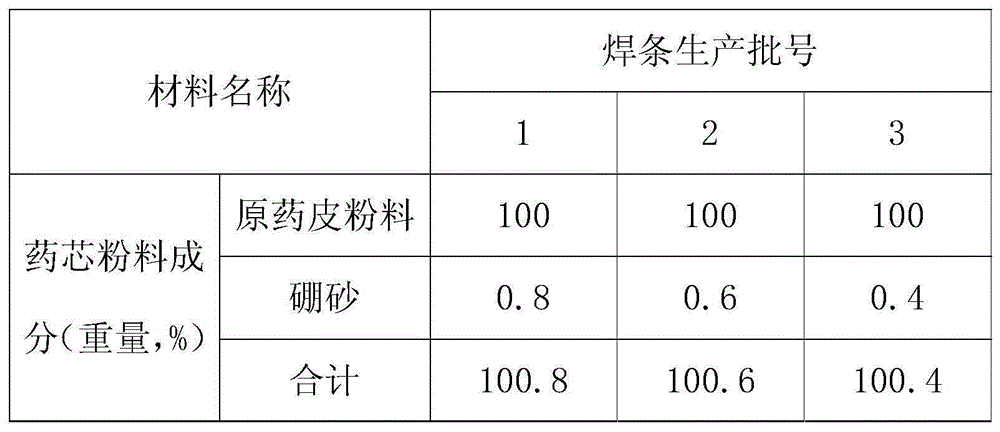

[0019] Table 3 embodiment - 12MnCrNi steel matching manual electrode coating composition (weight, %)

[0020]

[0021] Potassium sodium mixed with water glass is used for bonding, and the outer diameter of the coating is 6.0mm.

[0022] The embodiment of table 4 - the base metal and welding process parameters of three batches of welding rods

[0023]

[0024] Table 5 Example - three batches of electrode deposited metal chemical composition and mechanical properties

[0025]

[0026] Table 6 Chemical composition and mechanical properties of deposited metal of 12MnCrNi steel with manual electrode without boride coating

[0027]

[0028] It can be seen that compared with ...

Embodiment 2

[0030] The metallurgical method according to the present invention was implemented in an improved design of 350 flux. Design and make three batches of flux containing B 2 o 3 The 350G flux, the flux production method is the same as the original 350 flux. The components of the three batches of flux are shown in Table 7, respectively. The welding wire for the three batches of flux is 12MnCrNi (size 4mm), and the base metal and welding process parameters are shown in Table 8. After welding, the mechanical properties of the deposited metal were tested, and the test results are shown in Table 9.

[0031] Table 7 Example - 350G flux composition (weight, %)

[0032]

[0033] Table 8 Example - Base metal and welding process parameters welded by three batches of flux 350G

[0034]

[0035] Table 9 Examples - Chemical Composition and Mechanical Properties of Deposited Metal

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com