Quick heating method for graphene and deep processing method based on same

A rapid heating and graphene technology, applied in the direction of graphene, chemical instruments and methods, sustainable manufacturing/processing, etc., to achieve the effect of improving energy utilization and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

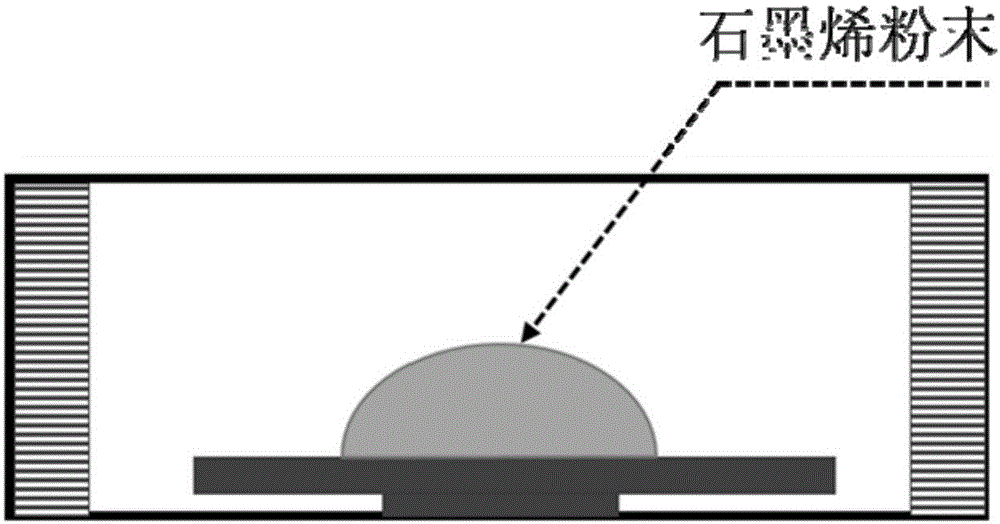

[0041] Get 60mg thermally exfoliated graphene as raw material, such as figure 1 As shown, a microwave oven is used in the air to act on the sample, the microwave power is set to 700w, and the heating time is 1 minute to prepare porous graphene. The transmission electron microscope pictures of the raw materials used are as follows: figure 1 As shown, there are no holes on the surface of graphene nanosheets; the transmission electron microscope photos of the prepared porous graphene are as follows figure 2 As shown, the graphene surface is punched with holes about 20nm in size.

Embodiment 2

[0043] Using the same raw material and process as in Example 1, the heating time was increased to 10min to prepare porous graphene. The transmission electron microscope photographs of the prepared porous graphene are as follows: image 3 As shown, the graphene surface is punched with holes of 100nm in size.

Embodiment 3

[0045] Take 50 mg of graphene oxide as raw material, and heat it for 2 seconds with a 1kw infrared lamp in the air for deoxygenation and purification. The comparison sample was before infrared action ( Figure 5 ) and after infrared ( Figure 6 ) of the Fourier transform infrared spectrum, it can be found that the 1730cm in the raw material -1 Stretching vibration absorption peak of nearby C=O double bond, 1620cm -1 The vibrational absorption peak of the nearby O-H bond, 1217cm -1 The vibrational absorption peak of the nearby C-OH bond and the 1043cm -1 The vibrational absorption peaks of nearby C-O-C bonds are obviously weakened or disappeared. Simultaneous XPS analysis ( Figure 7 ) also showed that the oxygen content of the sample decreased significantly after infrared treatment. These data indicate that oxygen-containing groups were effectively removed for purification purposes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com