Refuse lac chain-extended modification powder and preparation method thereof

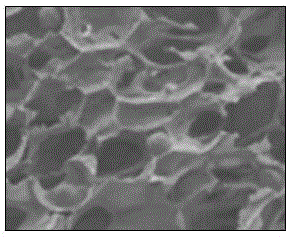

A technology of modified powder and slag glue, applied in the field of chain extension modified powder and its preparation, can solve the problems of unsuitable chain extension modification, toxicity of chain extension agent, etc., and achieve good mechanical strength, biodegradability, and reaction temperature. The effect of low, uniform cell structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: The chain extension modified powder composition of the lac waste slag is: dehydrated lac waste slag 100g, triglycidyl isocyanurate (TGIC) 5g;

[0026] The preparation method of the above-mentioned modified powder: heat the waste lac residue at 80°C for 12 hours in a vacuum to remove the moisture in the waste lac residue to obtain the waste lac residue; take 100g of the waste lac residue and add it to the grinding Finely powdered chain extender TGIC 5g, stirred and mixed for 15 minutes to obtain a liquid mixture; heated in an oven at 100°C for 6 hours to carry out chain extension reaction, and obtained shellac waste slag rubber chain extension modified product; pulverized by tissue pulverizer After passing through a 100-mesh sieve, the shellac waste slag glue chain extension modified powder is obtained.

Embodiment 2

[0027] Example 2: The composition of the chain-extended modified powder of lac waste slag is: 100 g of dehydrated lac waste slag, 13 g of triglycidyl isocyanurate (TGIC);

[0028] The preparation method of the above-mentioned modified powder: heat the waste lac residue at 80°C for 12 hours in a vacuum to remove water to obtain the waste lac residue; take 100g of the waste lac residue and add a chain extender that is ground into a fine powder TGIC 13g, stirred and mixed for 15 minutes to obtain a liquid mixture, which was heated in an oven at 120°C for 2 hours to carry out chain extension reaction to obtain a chain extension modified product of shellac waste slag, which was pulverized by a tissue grinder and passed through a 100-mesh sieve. That is, the chain-extended modified powder of shellac waste slag is obtained.

Embodiment 3

[0029] Example 3: The chain-extended modified powder composition of the shellac waste residue is: dehydrated shellac waste residue 100g, triglycidyl isocyanurate (TGIC) 8g;

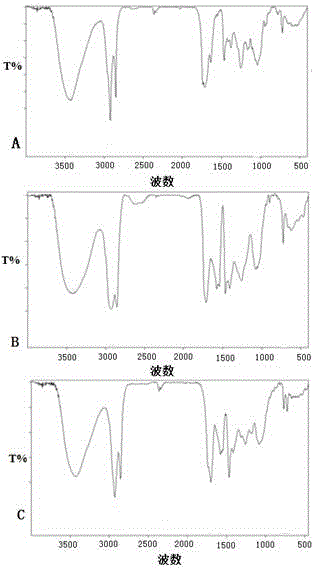

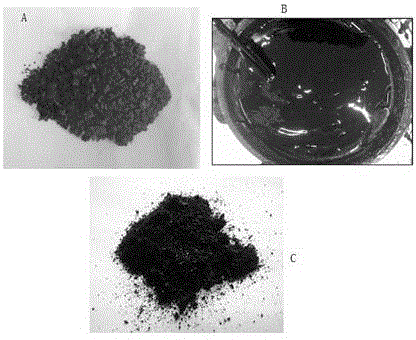

[0030] The preparation method of the above-mentioned modified powder: heat the waste lac residue at 75°C for 12 hours in a vacuum to remove the moisture in the waste lac residue to obtain the waste lac residue; take 100g of the waste lac residue and add it to the grinding Finely powdered chain extender TGIC 8g, stirred and mixed for 15 minutes to obtain a liquid mixture; heated in an oven at 110°C for 4 hours to carry out chain extension reaction, and obtained shellac waste slag rubber chain extension modified product; pulverized by tissue pulverizer After passing through a 100-mesh sieve, the shellac waste slag glue chain extension modified powder ( figure 1 , 2 ).

[0031] From figure 2 It can be seen that the lac particles have its typical purple-red particle characteristics ( figure 2 A), but th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com