Synthetic leather for swivel chair and preparation method for synthetic leather

A technology for synthetic leather and swivel chair, applied in the field of synthetic leather for swivel chair and its preparation, can solve the problems of poor air permeability of synthetic leather, poor anti-corrosion and acid-proof performance, corrosion of the bottom layer and surface layer, etc., and achieves good moisture dissipation performance and air permeability Strong performance and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

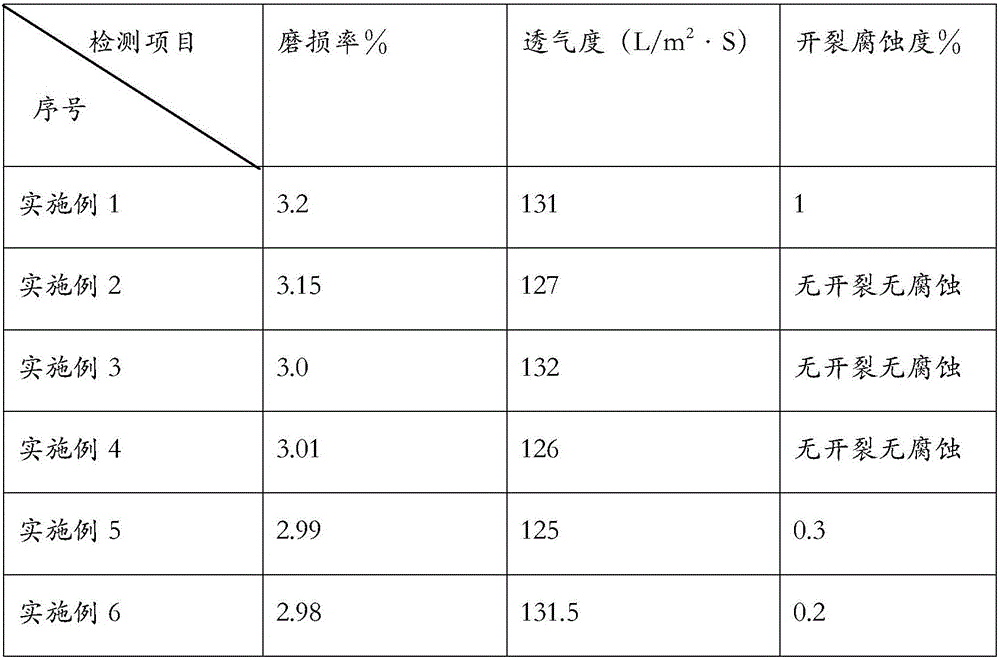

Examples

Embodiment 1

[0026] A synthetic leather for a swivel chair, comprising a bottom layer and a top layer; the top layer is attached to both sides of the bottom layer; the top layer includes the following components by weight: 100 parts of PVC resin, 50 parts of plasticizer, 20 parts of aramid fiber, 20 parts of silk fiber, and 5 parts of foaming agent; the weight and number ratio of aramid fiber and silk fiber is 1; the bottom layer includes the following components by weight: 100 parts of PVC resin, 30 parts of calcium carbonate 5 parts, 5 parts of stabilizer, 5 parts of polytetrafluoroethylene.

[0027] A preparation method of synthetic leather for a swivel chair, the steps are as follows:

[0028] (1) Preparation of the bottom layer:

[0029] a. Stir and mix the components of the bottom layer in a mixer according to their parts by weight; the mixing time is controlled at 40min;

[0030] b. Kneading, kneading and calendering the mixed materials to obtain the bottom layer.

[0031] (2) Pr...

Embodiment 2

[0038] A synthetic leather for a swivel chair, comprising a bottom layer and a top layer; the top layer is attached to both sides of the bottom layer; the top layer includes the following components by weight: 100 parts of PVC resin, 52 parts of plasticizer, 24 parts of aramid fiber, 22 parts of silk fiber, and 7 parts of foaming agent; the weight and number ratio of aramid fiber and silk fiber is 1.09; the bottom layer includes the following components by weight: 100 parts of PVC resin, 33 parts of calcium carbonate parts, 7 parts of stabilizer, 6 parts of polytetrafluoroethylene.

[0039] A preparation method of synthetic leather for a swivel chair, the steps are as follows:

[0040] (1) Preparation of the bottom layer:

[0041] a. Stir and mix the components of the bottom layer in a blender according to their parts by weight; the stirring time is controlled at 42min;

[0042] b. Kneading, kneading and calendering the mixed materials to obtain the bottom layer.

[0043] (...

Embodiment 3

[0050] A synthetic leather for a swivel chair, comprising a bottom layer and a top layer; the top layer is attached to both sides of the bottom layer; the top layer includes the following components by weight: 100 parts of PVC resin, 55 parts of plasticizer, 25 parts of aramid fiber, 25 parts of silk fiber, and 7 parts of foaming agent; the weight and number ratio of aramid fiber and silk fiber is 1; the bottom layer includes the following components by weight: 100 parts of PVC resin, 35 parts of calcium carbonate 7 parts, 7 parts of stabilizer, 7 parts of polytetrafluoroethylene.

[0051] A preparation method of synthetic leather for a swivel chair, the steps are as follows:

[0052] (1) Preparation of the bottom layer:

[0053] a. Stir and mix the components of the bottom layer in a mixer according to their parts by weight; the mixing time is controlled at 45min;

[0054] b. Kneading, kneading and calendering the mixed materials to obtain the bottom layer.

[0055] (2) Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com