Linear NTC thermosensitive polymer composite and preparation method thereof

A composite material and polymer technology, which is applied in the field of linear NTC thermosensitive polymer composite materials and its preparation, can solve the problems of environmental hazards, poor linearity, and limited applications, and achieve good stability and good linearity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

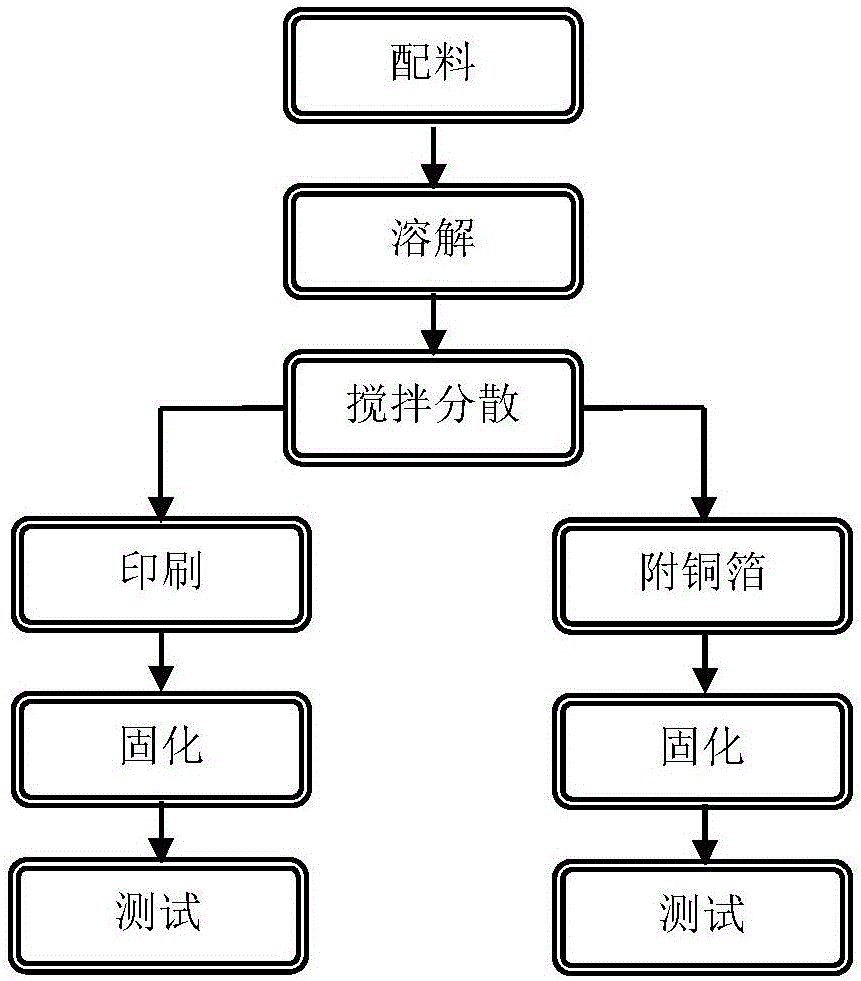

Method used

Image

Examples

Embodiment 1

[0042] (1) Ingredients, stirring and dispersing

[0043] According to the mass ratio of 0.9 part of fluororubber and 0.1 part of conductive carbon black, the raw material specifications are as shown in Table 1;

[0044] Then, take an appropriate amount of solvent butyl citrate, use butyl citrate for the weighed solid fluororubber, and add 0.12% phosphate coupling agent at the same time; after the fluororubber is completely dissolved, stir Gradually add conductive carbon black under certain conditions, and then continue to stir for 5 to 8 hours until the carbon black is completely and uniformly dispersed in the fluororubber, and finally pour it out and filter to obtain the fluororubber-carbon black liquid polymer composite material.

[0045] Table 1 Experimental raw materials and specifications

[0046] raw material grade or specification fluororubber solid or liquid carbon black nanoscale Tributyl citrate Analytical pure Phosphate coupling ...

Embodiment 2

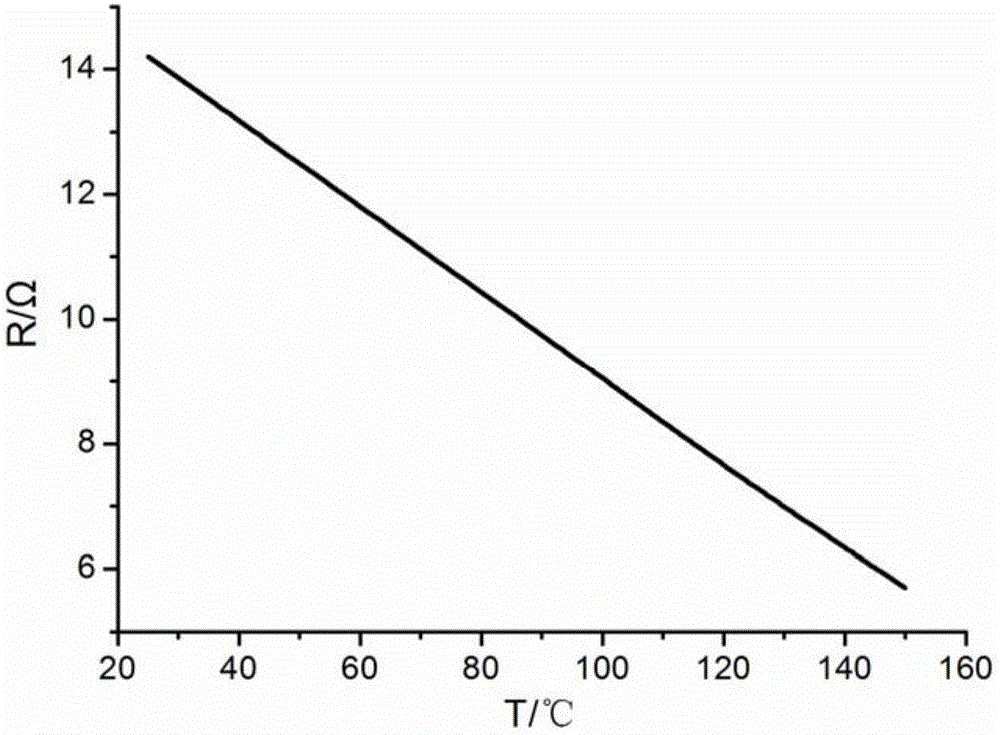

[0066] According to the mass ratio of 0.75 parts of fluororubber and 0.25 parts of conductive carbon black, the raw material specifications are shown in Table 1. Weigh an appropriate amount of solvent butyl citrate, dissolve the weighed fluororubber with butyl citrate, and add 0.2% phosphate coupling agent at the same time. Gradually add conductive carbon black, and continue to stir for 5 to 8 hours until the conductive carbon black is completely and uniformly dispersed in the fluororubber, and finally pour it out and filter to obtain the fluororubber-carbon black liquid polymer composite material. Then, a linear NTC thermistor sample was prepared by covering the copper foil, and the size of the sample was 15×15×2.5 mm. The specific operation process was the same as in Example 1.

[0067] 1) Test the resistance of the samples at 25°C, 85°C, 105°C, 125°C and 150°C respectively, as shown in Table 5,

[0068] Table 5 Variation of resistance of polymer composites with temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature resistivity | aaaaa | aaaaa |

| Room temperature resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com