Device and method for continuously producing high-adhesive-force aluminized film

A high-adhesion, aluminum-coated film technology, applied in sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve problems such as easy to fall off, poor adhesion of aluminum-coated films, etc., to achieve simple process, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

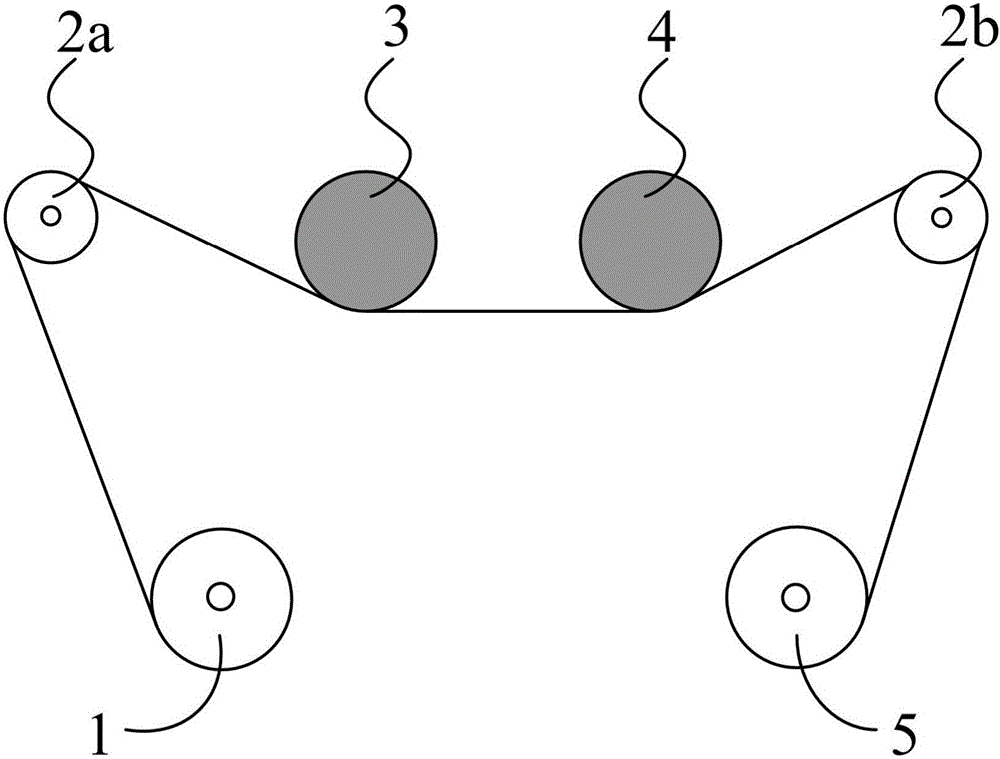

[0034] Use PET as the coating substrate, fix it on the substrate unwinding roller 1, and then evacuate to the background air pressure of 5×10 -3 Pa; start the unwinding roller 1 and the winding roller 5 power supply, set the winding speed to be 1000mm / min, pass into the sputtering gas argon in the sputtering chamber 3, and the air pressure is 8.4×10 -1 Pa, with the Al target as the sputtering target, the sputtering voltage is 380V, and the sputtering current is 6.2A to form a metal Al buffer layer; the aluminum film is evaporated by the aluminum wire thermal evaporation system in the coating chamber 4, and the thickness of the aluminum film is 115nm. Focus on the aluminum coating of 6.45N / 15mm.

Embodiment 2

[0036] Use PE as the coating substrate, fix it on the substrate unwinding roller 1, and then evacuate to the background air pressure of 6×10 -3 Pa; start the unwinding roller 1 and the winding roller 5 power supply, set the winding speed to be 2000mm / min, pass into the sputtering gas argon in the sputtering chamber 3, and the air pressure is 7.8×10 -1 Pa, using the Cr target as the sputtering target, the sputtering voltage is 385V, the sputtering current is 6.2A to form a metal Cr buffer layer; the aluminum film is evaporated by the aluminum wire thermal evaporation system in the coating chamber 4, and the thickness of the aluminum film is 86nm. Focus on the aluminized film of 5.33N / 15mm.

Embodiment 3

[0038] Use PET as the coating substrate, fix it on the substrate unwinding roller 1, and then evacuate to the background air pressure of 6×10 -3 Pa; start the power supply of unwinding roller 1 and winding roller 5, set the winding speed to be 300mm / min, pass into the sputtering gas argon and helium in the sputtering chamber 3, and the air pressure is 8.2×10 -1 Pa, using the Fe target as the sputtering target, the sputtering voltage is 380V, the sputtering current is 7.1A to form a metal Fe buffer layer; the aluminum film is deposited by the aluminum target sputtering system in the coating chamber 4, the thickness of the aluminum film is 40nm, and the adhesion is obtained 6.87N / 15mm aluminized film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com