A kind of liquid surface regulator for coating and preparation method thereof

A technology of liquid surface and regulator, which is applied in the coating process of metal materials, etc., can solve the problems of insignificant effect of aluminum alloy, need to improve corrosion resistance, poor stability of titanium colloid, etc., and achieve good activity retention performance and good versatility , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

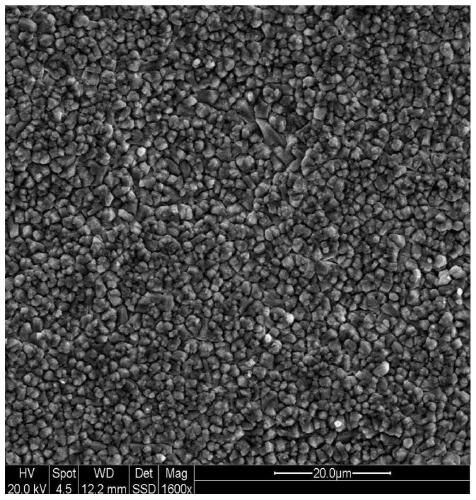

Image

Examples

Embodiment 1

[0026] A liquid surface conditioner for coating, each component includes by weight parts: 15 parts of a mixture of zinc phosphate and iron phosphate (the mass ratio of zinc phosphate and iron phosphate is 1:0.25), 9 parts of triethylhexyl phosphoric acid 8 parts, 8 parts of copper pyrophosphate, 8 parts of disodium dihydrogen pyrophosphate, 6 parts of hydrolyzed polymaleic anhydride, 1 part of sodium hydroxide, 53 parts of water; Its preparation method comprises the following steps:

[0027] Weigh deionized water according to the proportion, then add disodium dihydrogen pyrophosphate, triethylhexyl phosphoric acid and sodium hydroxide in sequence under stirring conditions, and then add the mixture of zinc phosphate and iron phosphate dispersed by ultrasonic disperser and hydrolyzate Maleic anhydride, keep it for 15 minutes, then add copper pyrophosphate to form a uniform mixture, finally add sodium hydroxide to the resulting mixture to adjust the pH value of the mixture between...

Embodiment 2

[0031] A liquid surface conditioner for coating, each component includes by weight parts: 20 parts of a mixture of zinc phosphate and iron phosphate (the mass ratio of zinc phosphate and iron phosphate is 1:0.25), 10 parts of triethylhexyl phosphoric acid 5 parts, 5 parts of copper pyrophosphate, 5 parts of disodium dihydrogen pyrophosphate, 5 parts of hydrolyzed polymaleic anhydride, 1 part of sodium hydroxide, 66 parts of water; Its preparation method comprises the following steps:

[0032] Weigh deionized water according to the proportion, then add disodium dihydrogen pyrophosphate, triethylhexyl phosphoric acid and sodium hydroxide in sequence under stirring conditions, and then add the mixture of zinc phosphate and iron phosphate dispersed by ultrasonic disperser and hydrolyzate Maleic anhydride, keep it for 15 minutes, then add copper pyrophosphate to form a uniform mixture, finally add sodium hydroxide to the resulting mixture to adjust the pH value of the mixture betwee...

Embodiment 3

[0035] A liquid surface conditioner for coating, each component includes in parts by weight: 10 parts of a mixture of zinc phosphate and iron phosphate (the mass ratio of zinc phosphate and iron phosphate is 1:0.25), 8 parts of triethylhexyl phosphoric acid 5 parts, 5 parts of copper pyrophosphate, 5 parts of disodium dihydrogen pyrophosphate, 5 parts of hydrolyzed polymaleic anhydride, 1 part of sodium hydroxide, 66 parts of water; Its preparation method comprises the following steps:

[0036] Weigh deionized water according to the proportion, then add disodium dihydrogen pyrophosphate, triethylhexyl phosphoric acid and sodium hydroxide in sequence under stirring conditions, and then add the mixture of zinc phosphate and iron phosphate dispersed by ultrasonic disperser and hydrolyzate Maleic anhydride, keep it for 15 minutes, then add copper pyrophosphate to form a uniform mixture, finally add sodium hydroxide to the resulting mixture to adjust the pH value of the mixture betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com