Diesel oil burning power system with diesel engine adopting alcohol ether fuel to burn

A technology for power systems and diesel engines, applied in combustion engines, machines/engines, mechanical equipment, etc., can solve problems such as increased maintenance costs, difficulty in meeting power requirements, and low diesel replacement rate, and achieve cost savings, stable and reliable startup and Operation, the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

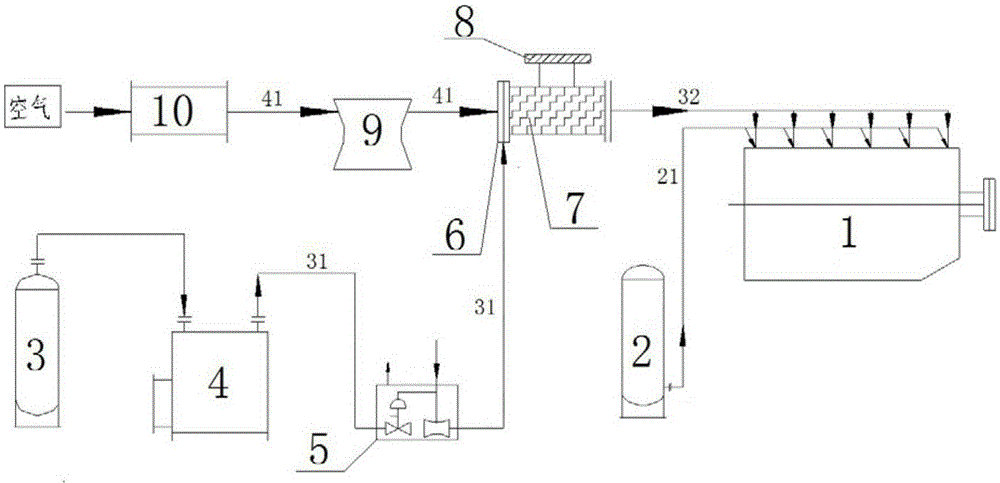

Method used

Image

Examples

Embodiment

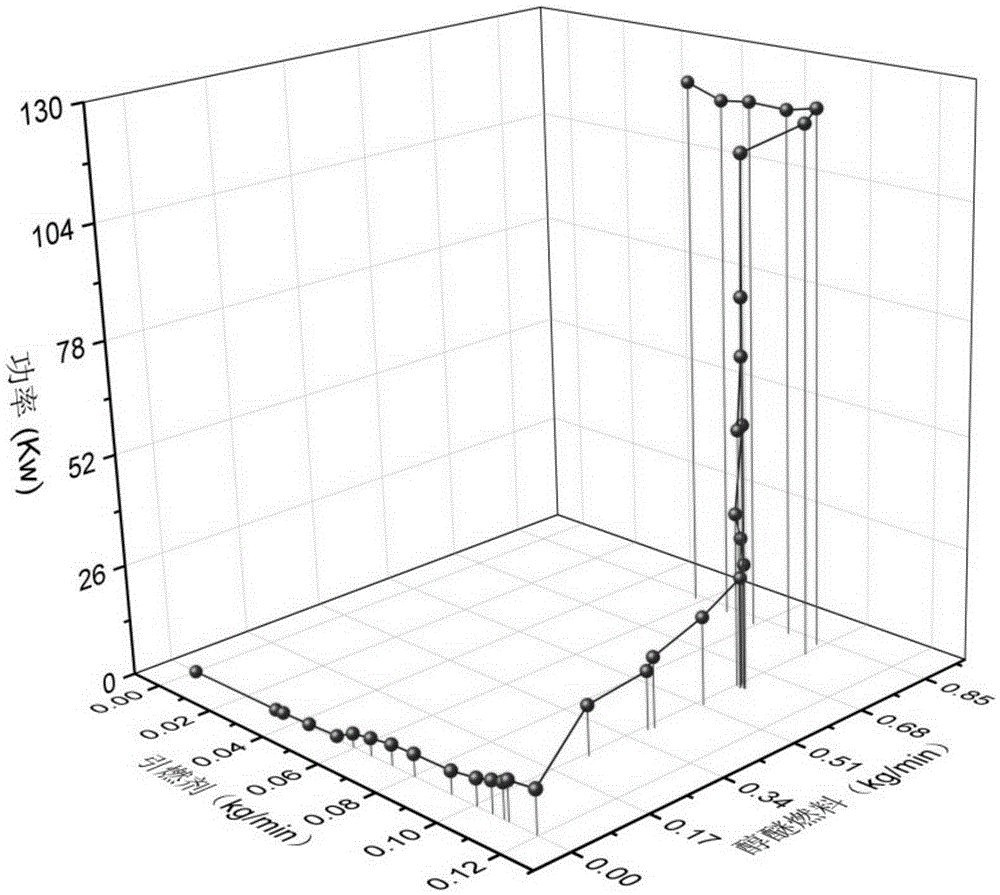

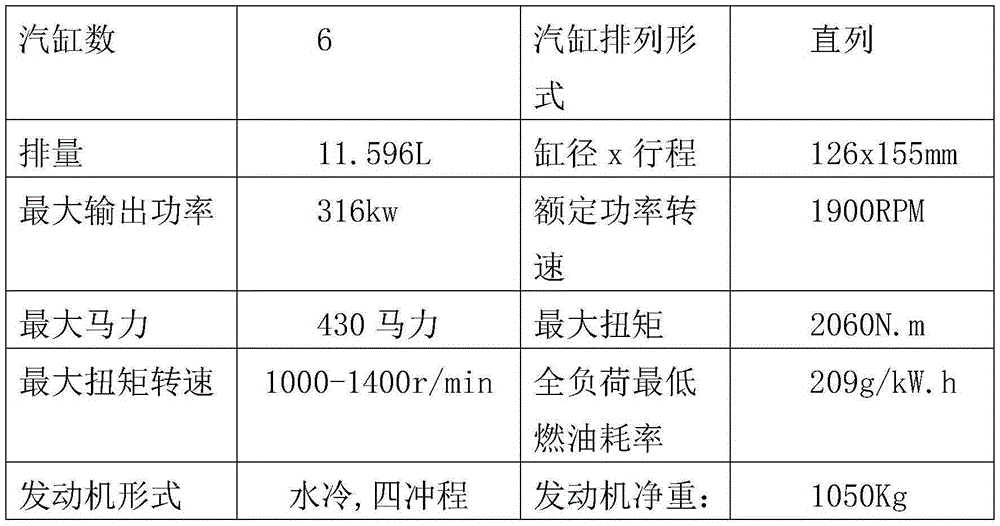

[0043] The system of the present invention has carried out a bench test on a 100-kilowatt six-cylinder diesel engine to verify the industrial feasibility. In the experiment, at a certain speed, the engine power change under the action of a igniter was tested with a high proportion of methanol alcohol ether fuel. The performance parameters and experimental data of the diesel engine used are shown in Table 1 and Table 2 respectively, and the power curve of the engine DMEV ignition start is shown in the attached figure 2 .

[0044] Table 1 Diesel engine technical parameter table

[0045]

[0046] Table 2 Bench experiment data table

[0047]

[0048]

[0049] *The liquid alcohol ether fuel in Table 2 is a mixture of methanol and dimethyl ether with a mass ratio of 90:10.

[0050] The power curve of engine DMEV ignition start is as follows: figure 2 shown. It can be seen from the figure that the engine (six-cylinder diesel engine) starts slowly and the output power ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap