A mems resonant torque sensor for measuring torsional properties of linear micro-nano materials

A technology of torque sensor and micro-nano material, which is applied in the direction of measuring device, torque measurement, instrument, etc., to achieve the effect of improving measurement accuracy, high sensitivity and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

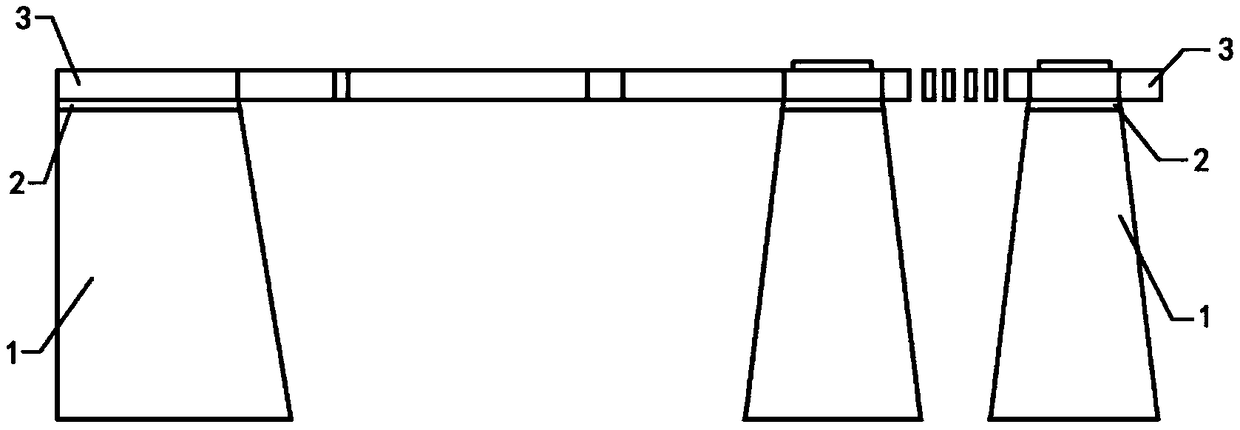

[0022] see figure 1 A MEMS resonant torque sensor for measuring torsional properties of linear micro-nano materials, comprising a monocrystalline silicon substrate 1 with a thickness ranging from 400um to 1000um, a silicon dioxide insulating layer 2 grown on the monocrystalline silicon substrate 1, and grown The thickness range is 2-3um, and the monocrystalline silicon structure layer 3 is arranged on the silicon dioxide insulating layer 2, and the thickness range is 10-25um.

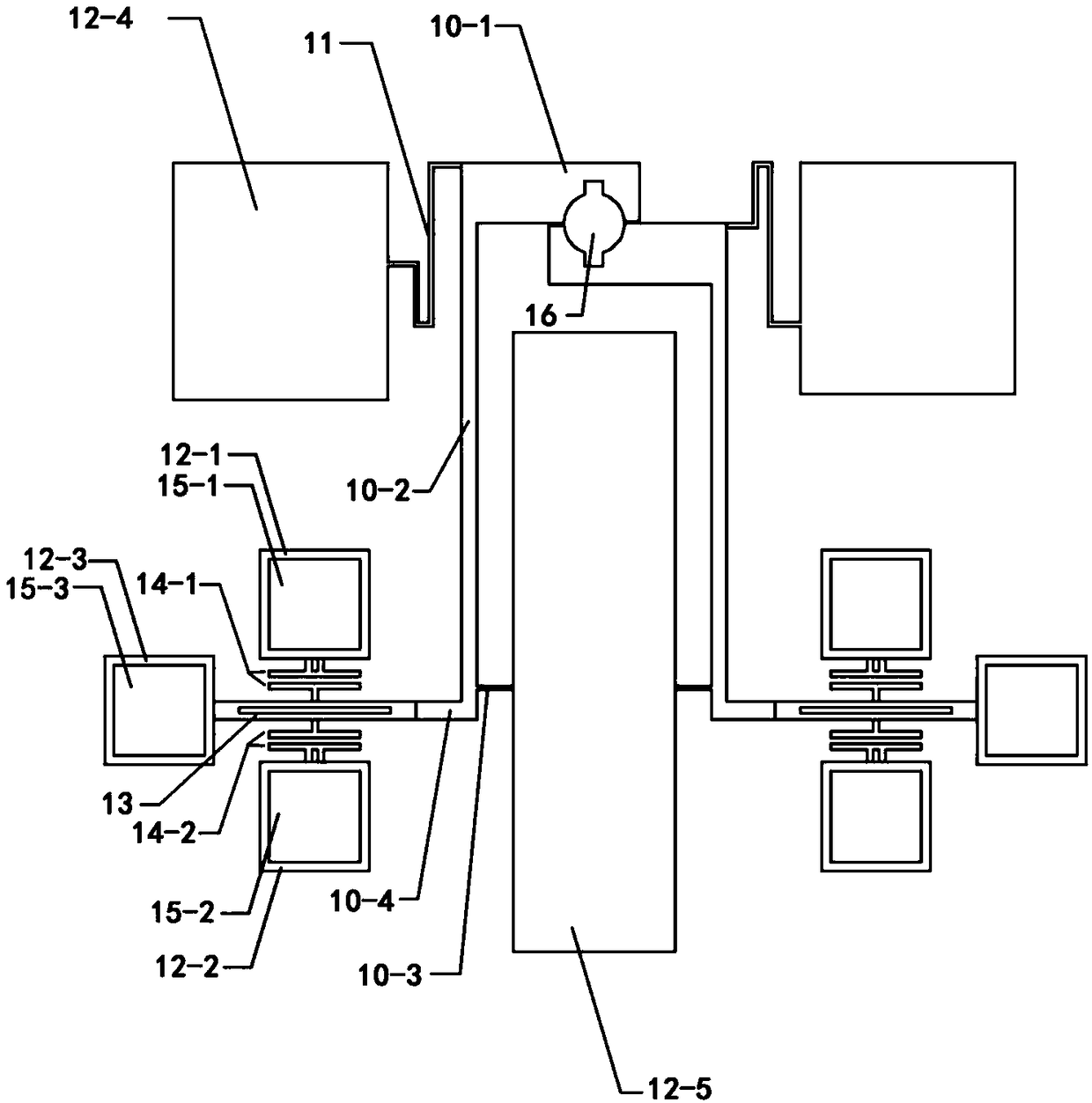

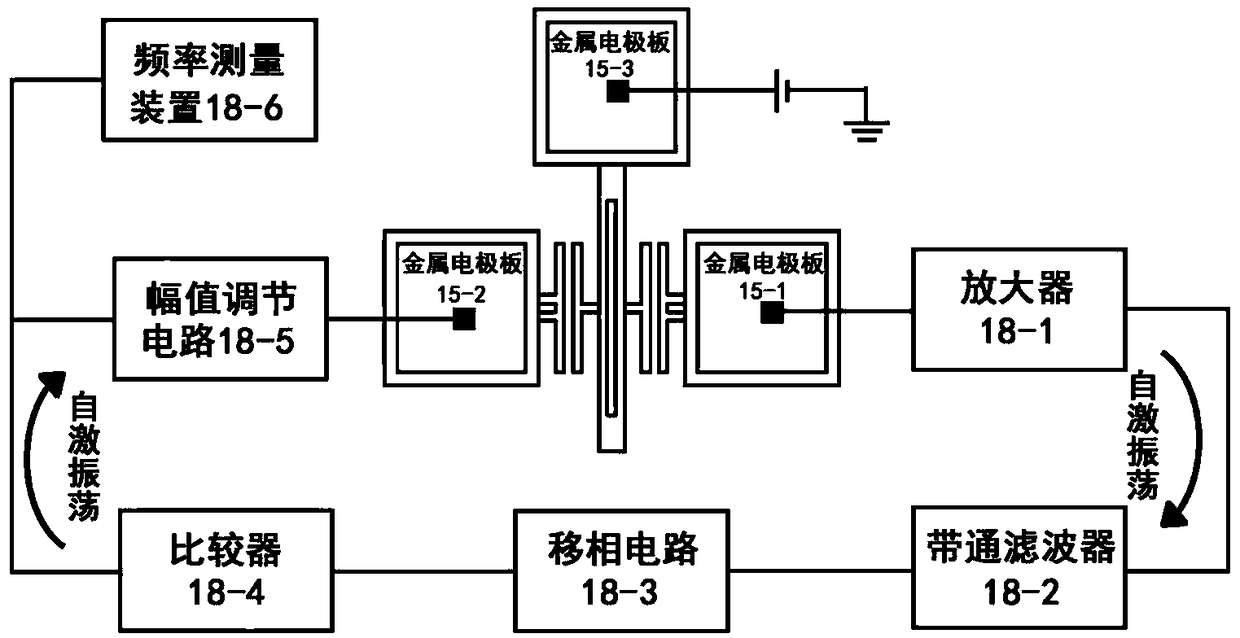

[0023] see figure 2 , the monocrystalline silicon structure layer 3 includes two opposite "Z" shaped micro-amplified beams, each "Z" shaped micro-amplified beam includes an input beam 10-1, a lever beam 10-2, and a fulcrum beam 10-3 And the output beam 10-4, the top of the lever beam 10-2 is connected with the input beam 10-1, the bottom of the lever beam 10-2 is connected with one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com