Bionic non-smooth surface friction resistance testing device based on underwater

A non-smooth surface, frictional resistance technology, applied in the direction of measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of high test cost, inaccurate data dispersion and long cycle of drag reduction test devices, and achieve structural Simple, easy to operate, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

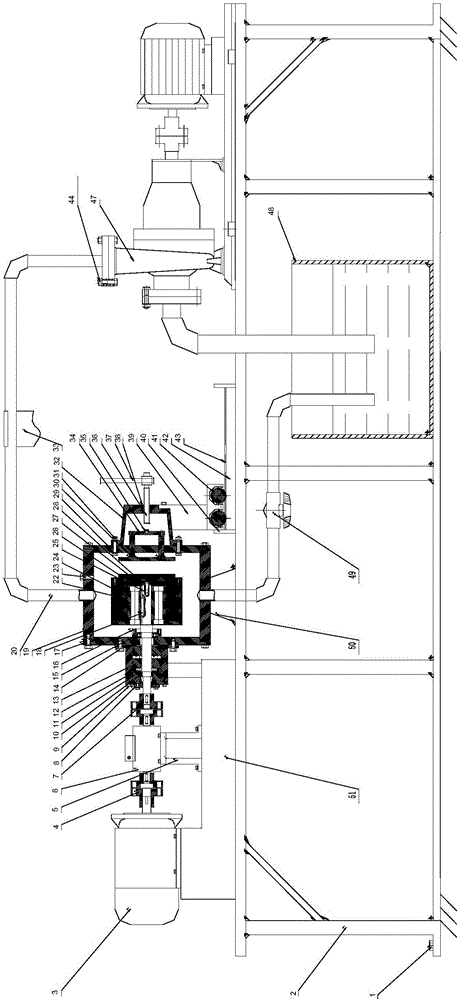

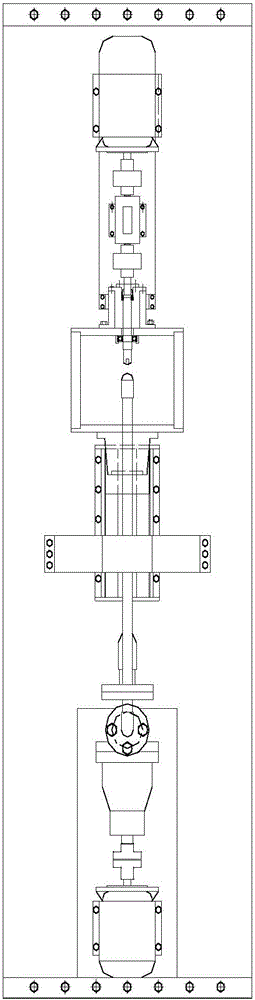

[0031] Embodiment 1 implements the underwater bionic non-smooth surface friction resistance testing device based on the present invention, comprising a test platform support, a rotating test component with a sealed cavity, a power input assembly, a water distribution assembly, a mobile assembly and a signal processing assembly. The above-mentioned rotating test parts, power input assembly and water distribution assembly are installed on the test platform support, and the moving assembly is welded to the test platform support; the power input assembly is connected to the test platform support through the first coupling The power input end of the signal processing component is connected, the power output end of the signal processing component is connected with one end of the rotating shaft of the rotating test component through a second coupling, and the other end of the rotating test component is installed with a moving component; The water inlet pipe of the water distribution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com