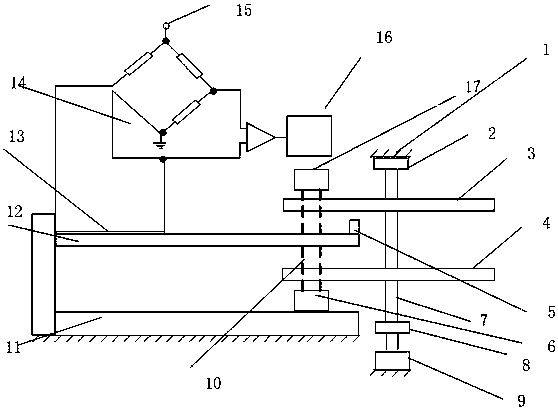

Apparatus and method for mass measurement of nanobeams and microparticles excited by light momentum

A quality measurement and nano-beam technology, applied in the field of nano-micro quality detection, can solve problems such as redundant noise, lower measurement accuracy, damage, etc., and achieve the effect of high measurement sensitivity and less measurement interference factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

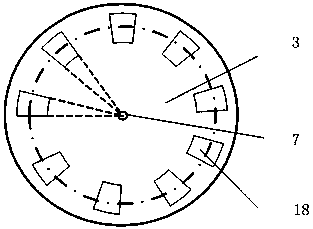

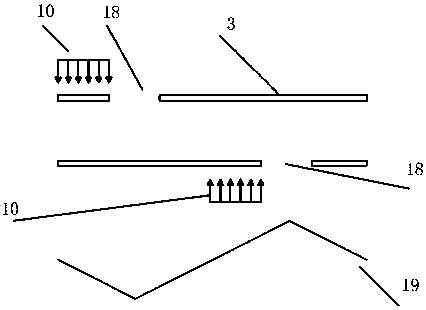

example 1

[0029] Example 1: Monochromatic light is vertically irradiated on the upper surface of the nanobeam 12, and the power P of the incident light passing through the light hole 18 is 1×10 -6 w, the force efficiency α of the incident light is 0.8, the refractive index n of the surrounding medium is 1, and the light speed c is 3×10 8 m / s, the number k of light holes on the disc is 1256, and the linear density of nanobeams 12 is 9.32×10 -9kg / m, the elastic modulus E of the nano-beam 12 is 170GPa, the length l of the nano-beam 12 is 40 μm, the width b of the nano-beam 12 is 5 μm, and the height h of the nano-beam 12 is 0.8 μm. The magnitude of the light momentum excitation force generated by the light radiation passing through the light hole 18 is 2.0×10 -3 nN.

[0030] When the nanobeam 12 resonates, it is measured that the rotation speed of the disk is 1700 revolutions per second, and the mass of the nanoparticle 5 is 2.7358×10 -15 kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com